Sand washing spray head for sand washing operation in ship coating operation and sand washing operation method thereof

A technology for sand washing and ships, which is applied in the direction of ship cleaning devices, devices for coating liquid on the surface, and ship hulls. It can solve the problems of increased difficulty in sand washing operations and difficulties in sand body flushing out, so as to improve the operating efficiency of employees and the company. The effects of labor productivity, ensuring product quality and production safety, improving team skill quality and job adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

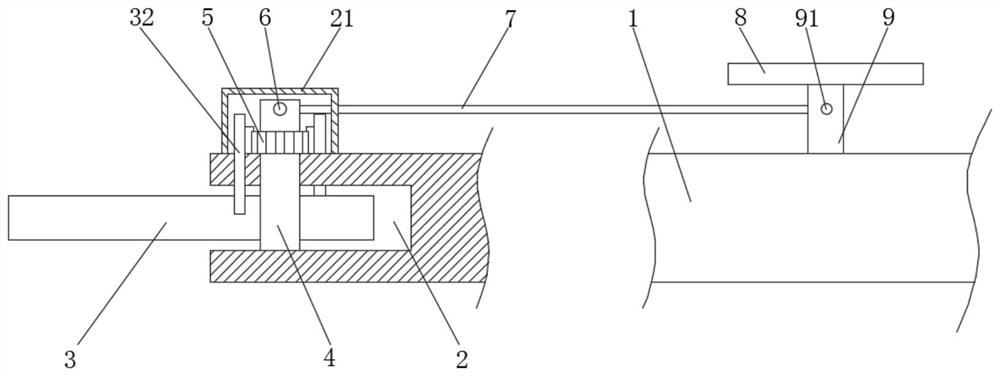

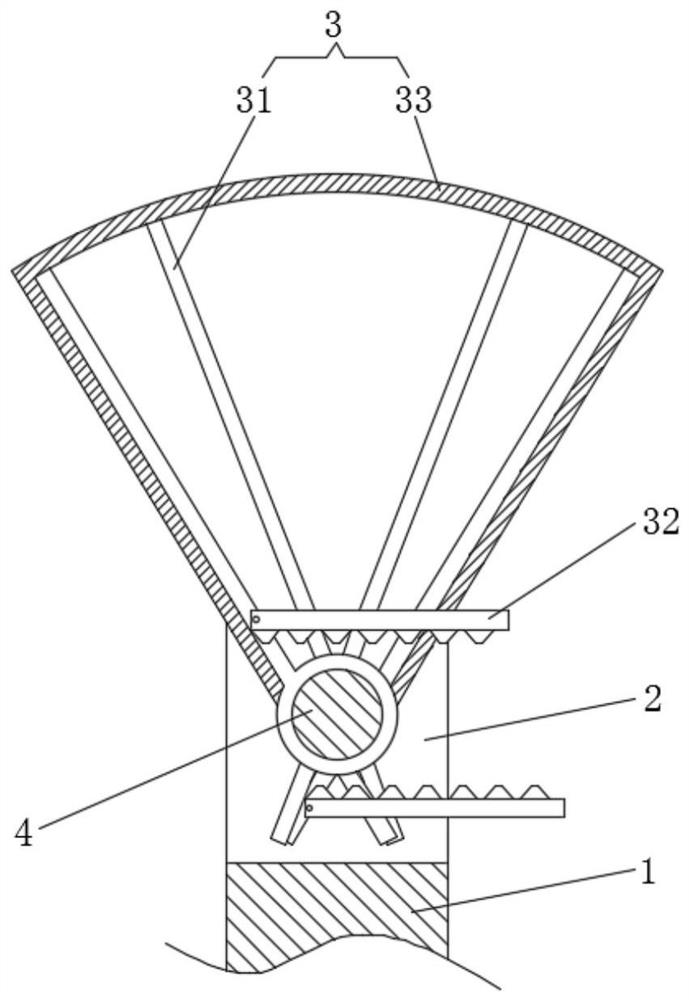

[0026] see Figure 1-3 , the present embodiment provides a sand washing spray head for sand washing operations in ship painting operations, including a water flow pipeline 1 connected to the sand washing machine, the output end of the water flow pipeline 1 is provided with a U-shaped fixed groove 2, and the inside of the fixed groove 2 The nozzle 3 is installed, and the interior of the fixed groove 2 is integrally provided with a rotating shaft 4. The top of the rotating shaft 4 extends to the outside of the fixing groove 2. The outer wall of the rotating shaft 4 is fixed with a gear 5 near the top, and the top of the rotating shaft 4 is integrally provided with a powerful rod 6. Two ends of the force bar 6 are respectively fixed with a torsion bar 7 , and one end of the torsion bar 7 away from the force bar 6 is connected with a turntable 8 to the outer wall of the water flow pipe 1 .

[0027] The nozzle 3 is composed of a plurality of movable rods 31 and a sealing cloth 33 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com