Full-automatic collecting device for hub paint spraying

A fully automatic, wheel-hub technology, applied in the direction of spraying devices, transportation and packaging, conveyor objects, etc., can solve the problems of affecting spraying efficiency, high physical strength consumption, and the danger of manual handling of hubs, and achieves the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

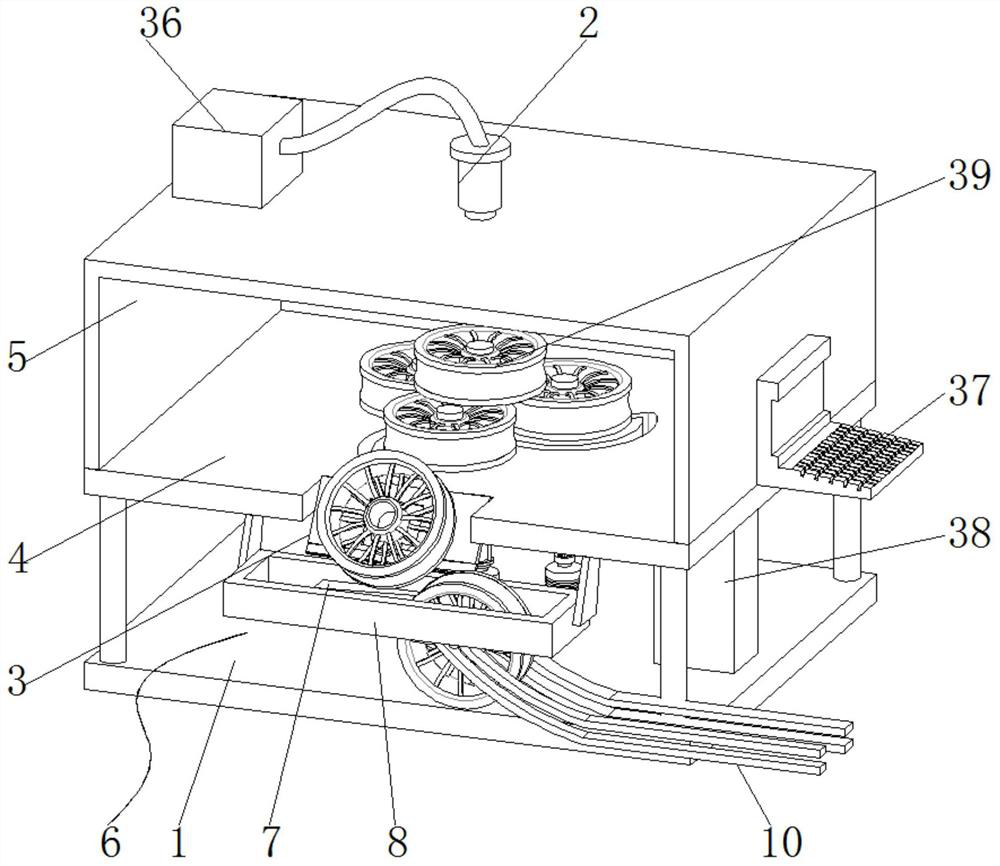

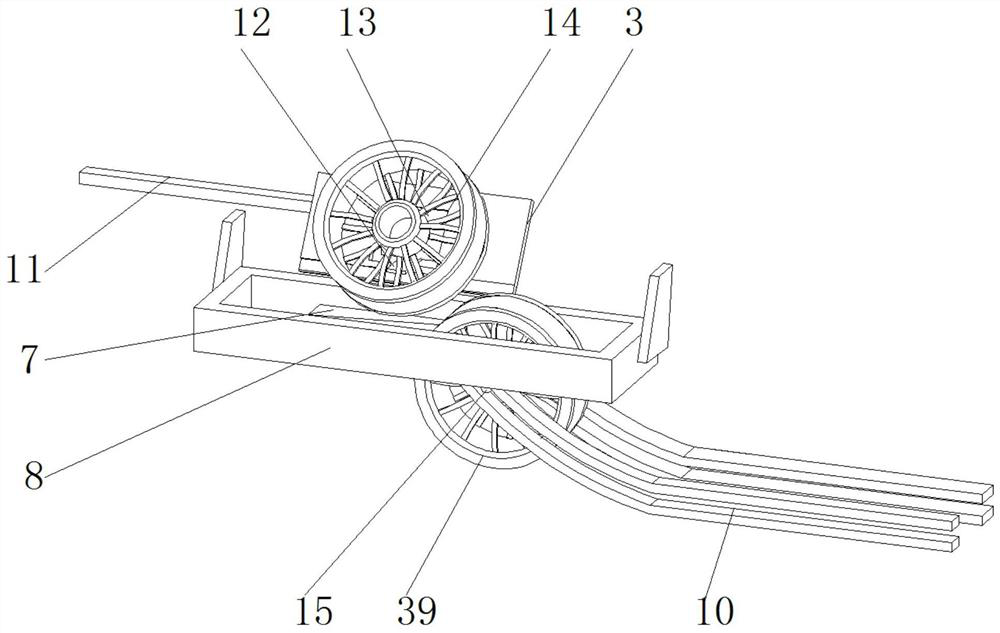

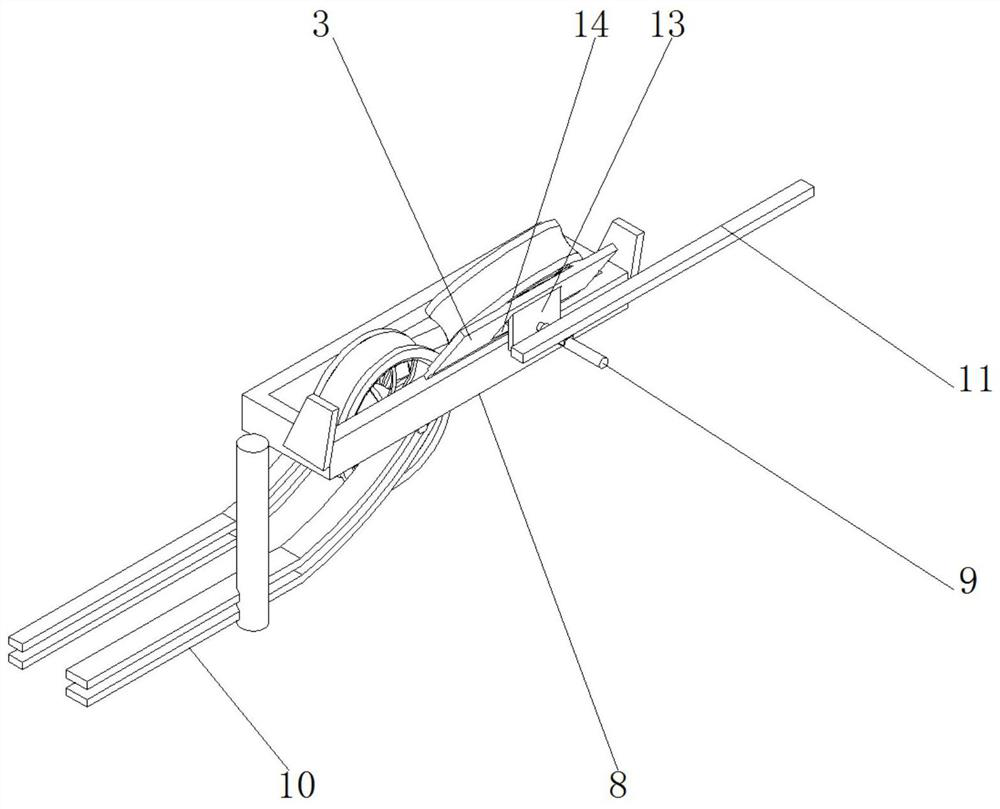

[0025] The embodiment of the present invention provides a kind of collection device for fully automatic wheel hub painting, such as Figure 1-9 As shown, it includes an iron base 1 , a paint spraying device 2 , a paint box 6 , a top plate 4 , an airtight cover 5 , a fetching mechanism 6 and a plurality of hubs 39 . The top board 4 is arranged on the base 1 , and the airtight cover 5 is arranged on the top board 4 . Both the paint spraying device 2 and the paint box 36 are arranged on the airtight cover 5 . The paint box 36 communicates with the paint spraying device 2 . A plurality of hubs 39 are arranged on the top board 4 , and the taking mechanism 6 is arranged on the top board 4 . The taking mechanism 6 includes a frame 8, a plurality of insertion rods 15, a turnover plate 3, two chute seats 10 and a trapezoidal block 7. One side of the turnover plate 3 is hinged on the front of the top plate 4 , and the frame 8 is arranged on the bottom of the top plate 4 . The frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com