Preparation method of porous doped flexible activated carbon gas adsorption film

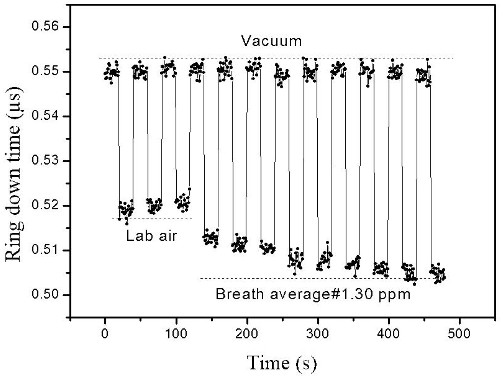

A gas adsorption, activated carbon technology, applied in separation methods, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem of difficult removal of interfering components, achieve good mechanical properties and thermal stability, and stable physical properties. Effects of chemical properties, controllable pore size distribution structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

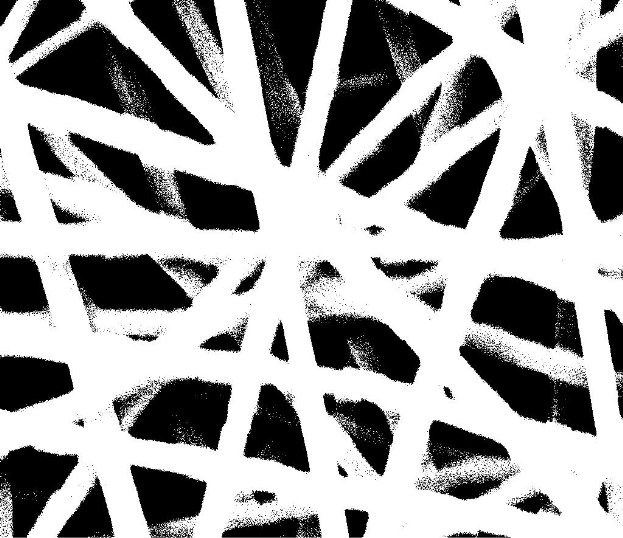

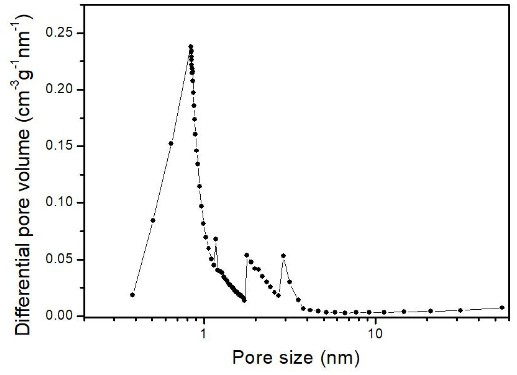

[0021] First, weigh 1g of polyacrylonitrile (PAN) powder, 0.1g of graphene oxide and stir to dissolve completely in 10ml of N,N-dimethylformamide (DMF) solvent; then put the dissolved PAN / DMF solution into Put it into a disposable syringe, install it on the electrospinning instrument, carry out electrospinning under the conditions of a voltage of 15kV, a receiving distance of 20cm, and a solution advancing speed of 0.005mm / s, and put the obtained fiber film into vacuum drying Drying in the middle: the temperature is 40°C; the drying time is 24h; finally, the dried PAN / GO membrane is pre-oxidized and carbonized and activated. The pre-oxidation conditions: the temperature is 200°C; the time is 2h; the heating rate is 1°C / min; the protective gas is air. Carbonization activation conditions: carbonization activation temperature is 600°C; holding time is 2h; heating rate is 5°C / min; protective gas is high-purity nitrogen. The carbonized and activated PAN / GO membrane was washed and...

Embodiment 2

[0024] First, weigh 0.5g of polyacrylonitrile (PAN) powder, 0.3g of graphene oxide and stir to completely dissolve in 10ml of N,N-dimethylformamide (DMF) solvent; then dissolve the dissolved PAN / DMF solution Put it into a disposable syringe, install it on an electrospinning instrument, perform electrospinning under the conditions of a voltage of 10kV, a receiving distance of 10cm, and a solution advancing speed of 0.001mm / s, and put the obtained fiber film into a vacuum Drying during drying: the temperature is 60°C; the drying time is 6h; finally, the dried PAN / GO membrane is pre-oxidized and carbonized and activated. The pre-oxidation conditions: the temperature is 100°C; the time is 2h; the heating rate is 5 ℃ / min; the protective gas is air. Carbonization activation conditions: carbonization activation temperature is 400°C; holding time is 2h; heating rate is 10°C / min; protective gas is high-purity nitrogen. The carbonized and activated PAN / GO membrane was washed and dried ...

Embodiment 3

[0026] First, weigh 10g of polyacrylonitrile (PAN) powder, 0.5g of graphene oxide and stir to dissolve completely in 100ml of N,N-dimethylformamide (DMF) solvent; then put the dissolved PAN / DMF solution into Put it into a disposable syringe, install it on the electrospinning instrument, carry out electrospinning under the conditions of a voltage of 25kV, a receiving distance of 30cm, and a solution advancing speed of 0.01mm / s, and put the obtained fiber film into vacuum drying Drying in the middle: the temperature is 60°C; the drying time is 36h; finally, the dried PAN / GO membrane is pre-oxidized and carbonized and activated, and the pre-oxidation conditions are: the temperature is 250°C; the time is 1h; the heating rate is 10°C / min; the protective gas is air. Carbonization activation conditions: carbonization activation temperature is 800°C; holding time is 4h; heating rate is 1°C / min; protective gas is high-purity nitrogen. The carbonized and activated PAN / GO membrane was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com