Novel magnetron sputtering device

A magnetron sputtering device and a new technology, applied in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problem of uneven distribution, low coating quality and coating efficiency, and poor target utilization. equality issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

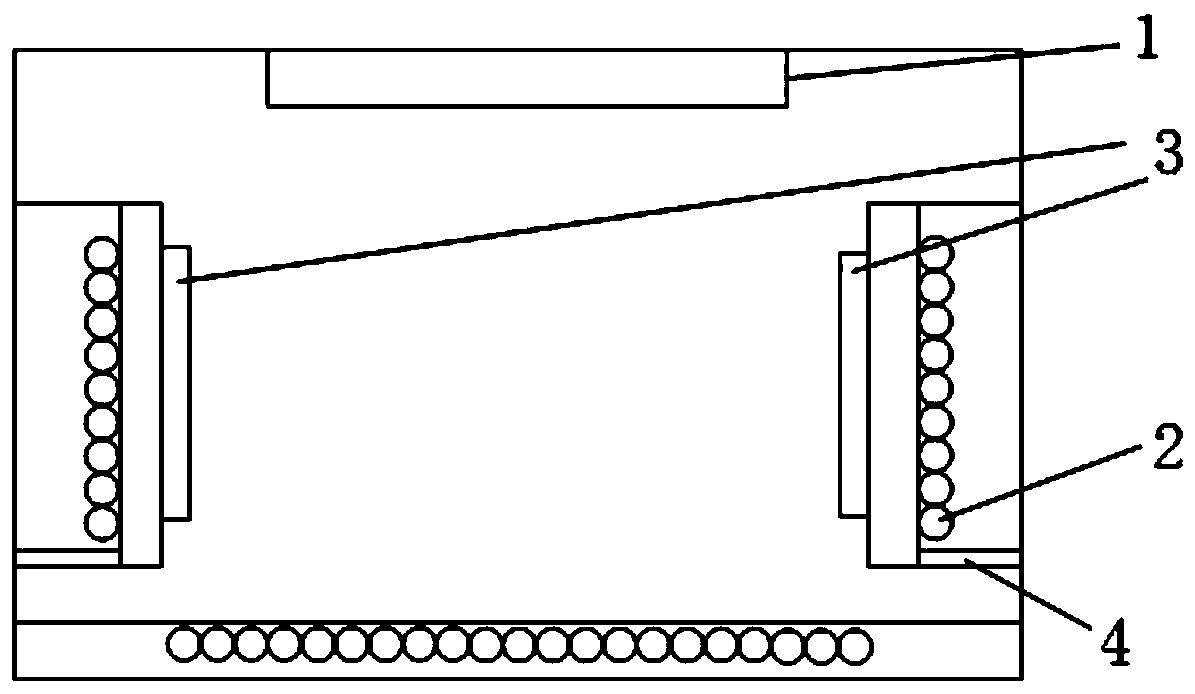

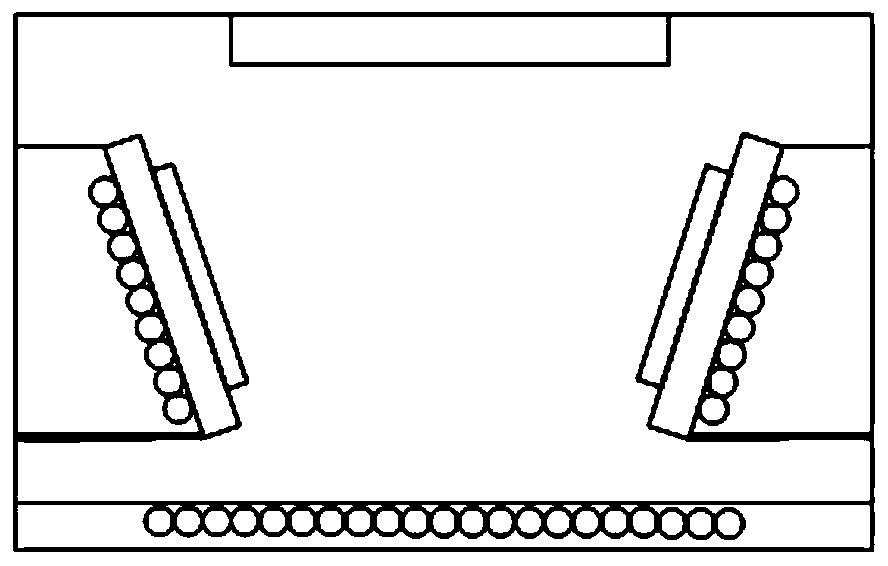

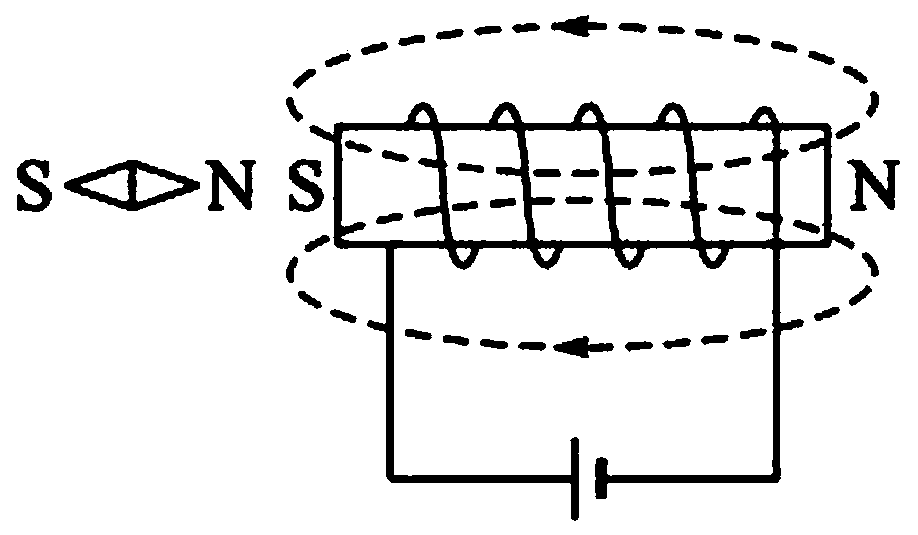

[0013] Such as figure 1 and figure 2 As shown, a novel magnetron sputtering device of the present invention includes a sputtering chamber and a solenoid 2, and a substrate 1 is fixed on the upper end of the sputtering chamber. A target 3 is arranged in the sputtering chamber, and the solenoids 2 are evenly distributed on the back of the target 1 and the bottom of the sputtering chamber, and each solenoid 2 is electrically connected to a power source. Such as image 3 As shown, each solenoid 2 can be energized separately to form an electromagnetic rod. The magnetic field distribution of the entire sputtering chamber can be controlled by adjusting the energization of each solenoid. A target inclination angle adjustment device is connected to the back of the target. In this embodiment, the target inclination angle adjustment device is a telescopic rod 4 connected to the lower end of the target back.

[0014] Such as figure 2 As shown, based on this, different materials can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com