A kind of preparation equipment and preparation process of polysilicon modified wear-resistant paste

A technology of modification and polysilicon, which is applied in the process of sub-atmospheric pressure, the method of chemically changing substances by using atmospheric pressure, chemical/physical/physicochemical processes, etc., can solve the problem of affecting the vacuum degree of the reactor and the mixing of the mixture impact, inconvenient feeding, etc., to achieve the effect of improving surface smoothness, good compatibility, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

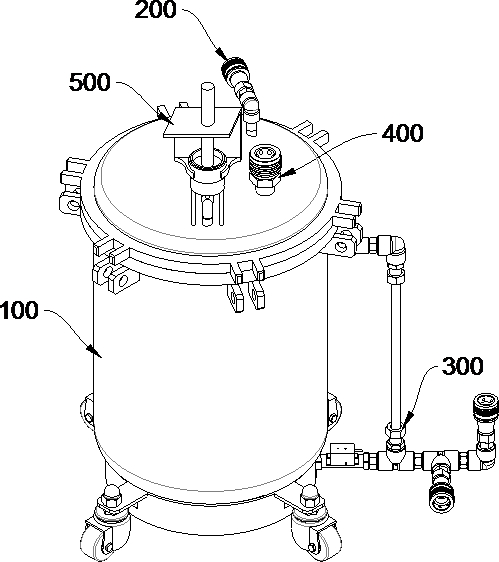

[0059] Please refer to Figure 1-10 , the present embodiment provides a polysilicon modified wear-resistant paste preparation equipment comprising: a reactor 100, a vacuum device 200, a heating device 300, a stirring device 400 and a feeding device 500; the reactor 100 has a top cover 1 and a discharge port 2; vacuum device 200 is used to regulate the degree of vacuum in reactor 100; Heating device 300 is used to heat the mixture in reactor 100; Stirring device 400 is used to stir the mixture in reactor 100; Feeding device 500 is used to react Putting materials in the kettle 100;

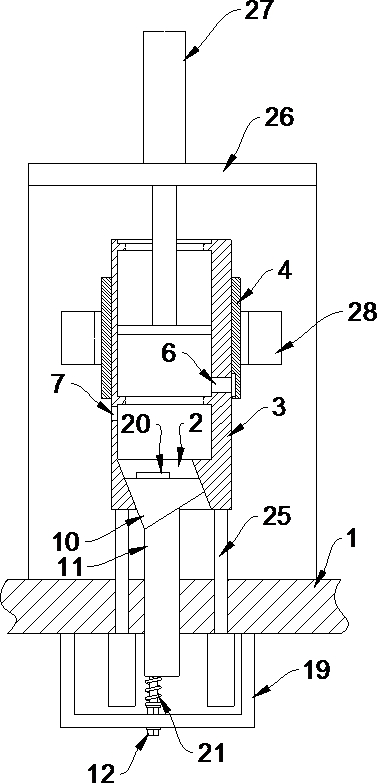

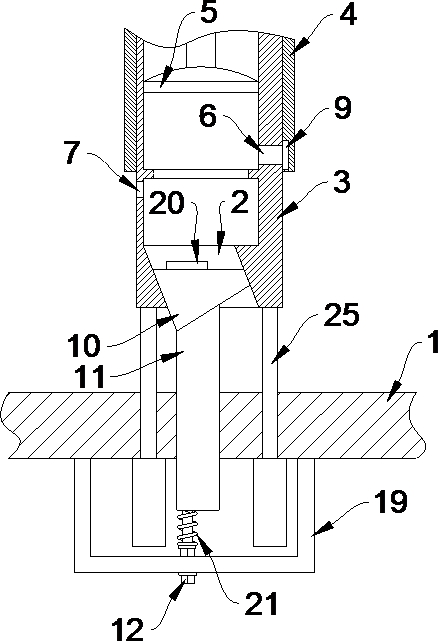

[0060] The feeding device 500 includes a storage bin 3, an exhaust bushing 4 and an exhaust piston 5. The storage bin 3 includes an exhaust section 31 and a feed section 32 that communicate with each other. The exhaust section 31 is provided with a first exhaust hole 6. , the feeding section 32 is provided with a feeding port 7, the feeding section 32 communicates with the inner cavity of the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com