An efficient drying equipment for nut production and processing and its application method

A technology for drying equipment and nuts, which is applied in the field of efficient drying equipment for nut production and processing, and can solve the problems of affecting the taste of nuts, falling nuts, and incomplete drying of nuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

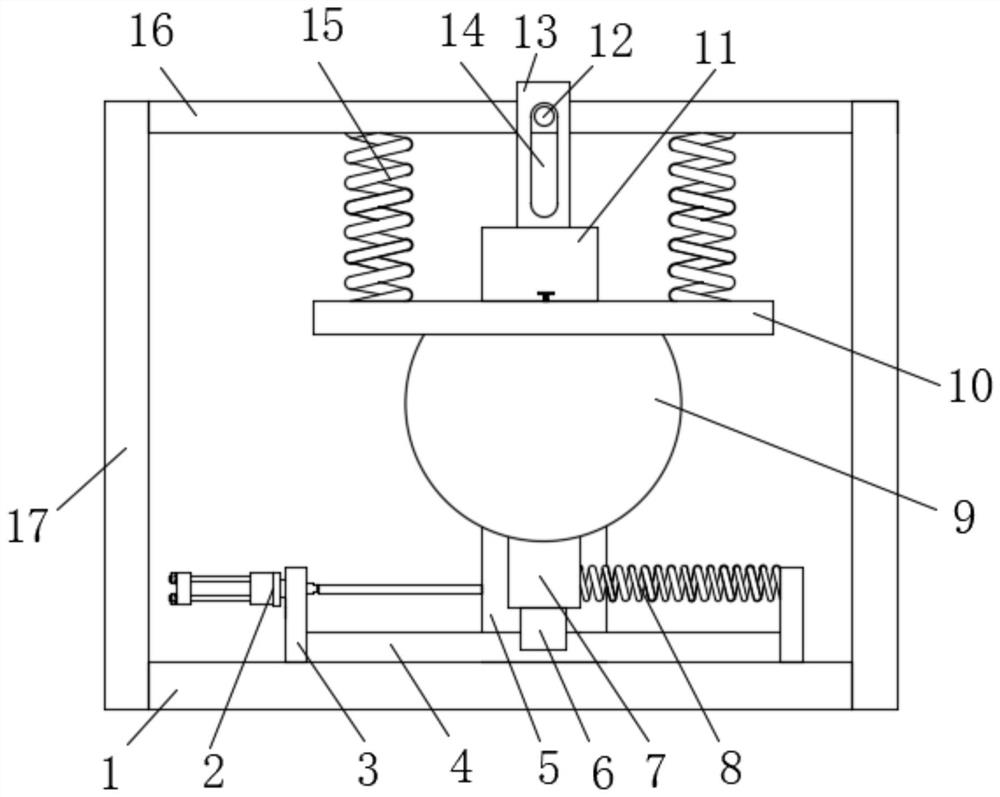

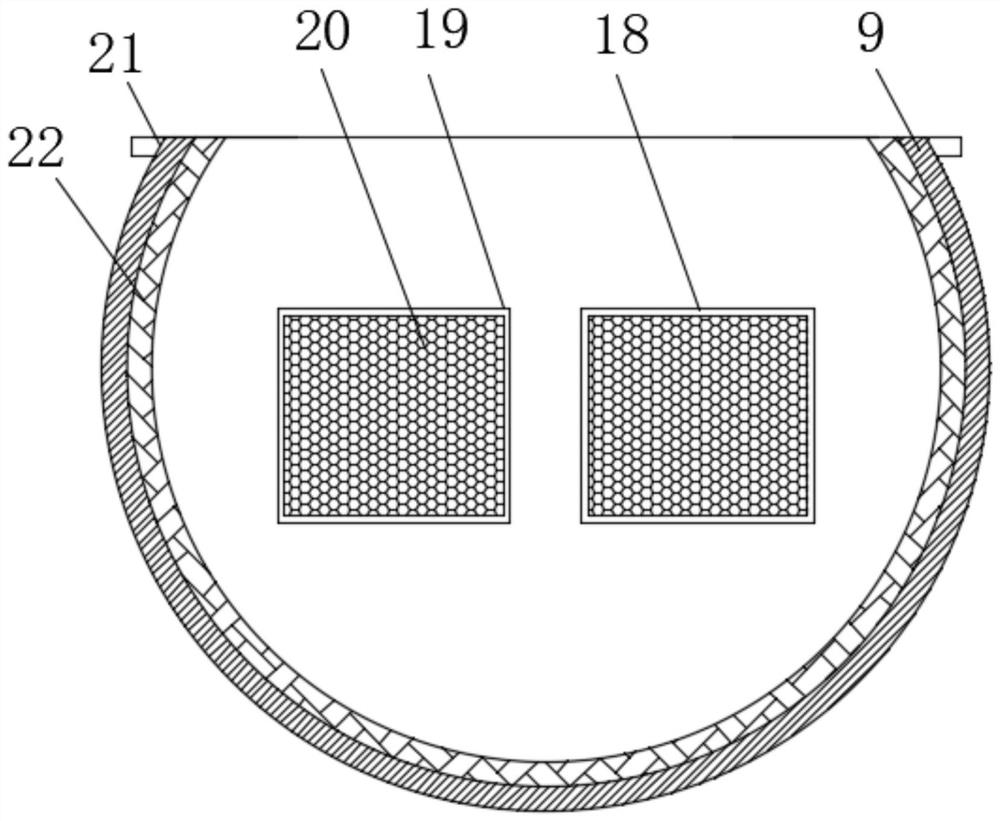

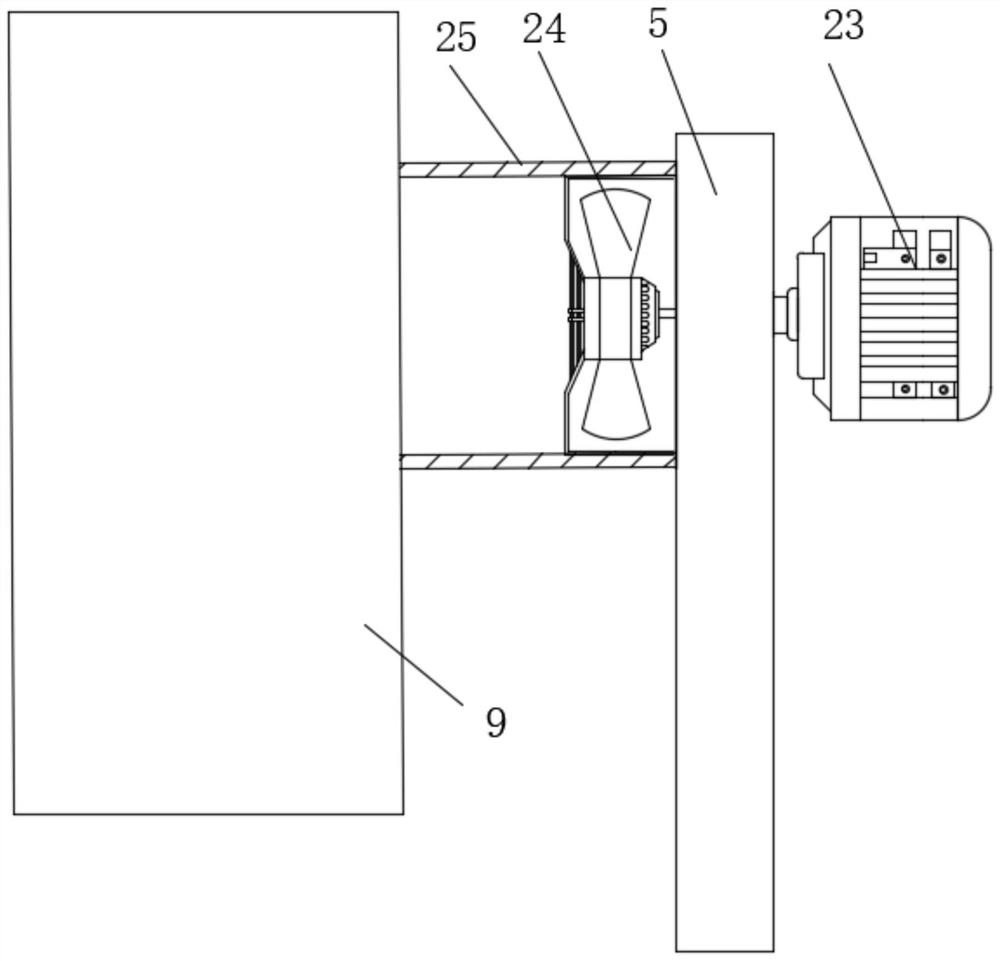

[0037] Example 1: Figure 1-8 As shown, an efficient nut production process drying device, including the bottom plate 1, both ends of the bottom plate 1 fixedly connected to the side plate 17, two side plates 17 are fixed to each other side fixed connection with a symmetric setting The top plate 16 is provided with a stirring assembly for stirring nuts, and the top portion of the bottom plate 1 is fixedly coupled with a fixing plate 5, and the fixed plate 5 is fixedly connected with a blown nut blowing assembly, the bottom plate 1 The top slide is connected to the connecting block 7, and the top of the connecting block 7 is fixedly coupled with the hollow cylinder 9, and the inside of the hollow barrel 9 has a drying assembly for the nut drying, and the top of the bottom plate 1 is provided with a push assembly for pushing the connection block 7. The top of the hollow cylinder 9 is provided with a closed assembly for covering the hollow cranks 9.

[0038] In the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com