Fermentation box for processing wheaten food

A technology of food processing and fermentation box, applied in the direction of dough fermenter, application, food science, etc., can solve problems such as reducing the processing efficiency of noodle food, and achieve the effects of preventing a large number of deaths, speeding up cooling, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

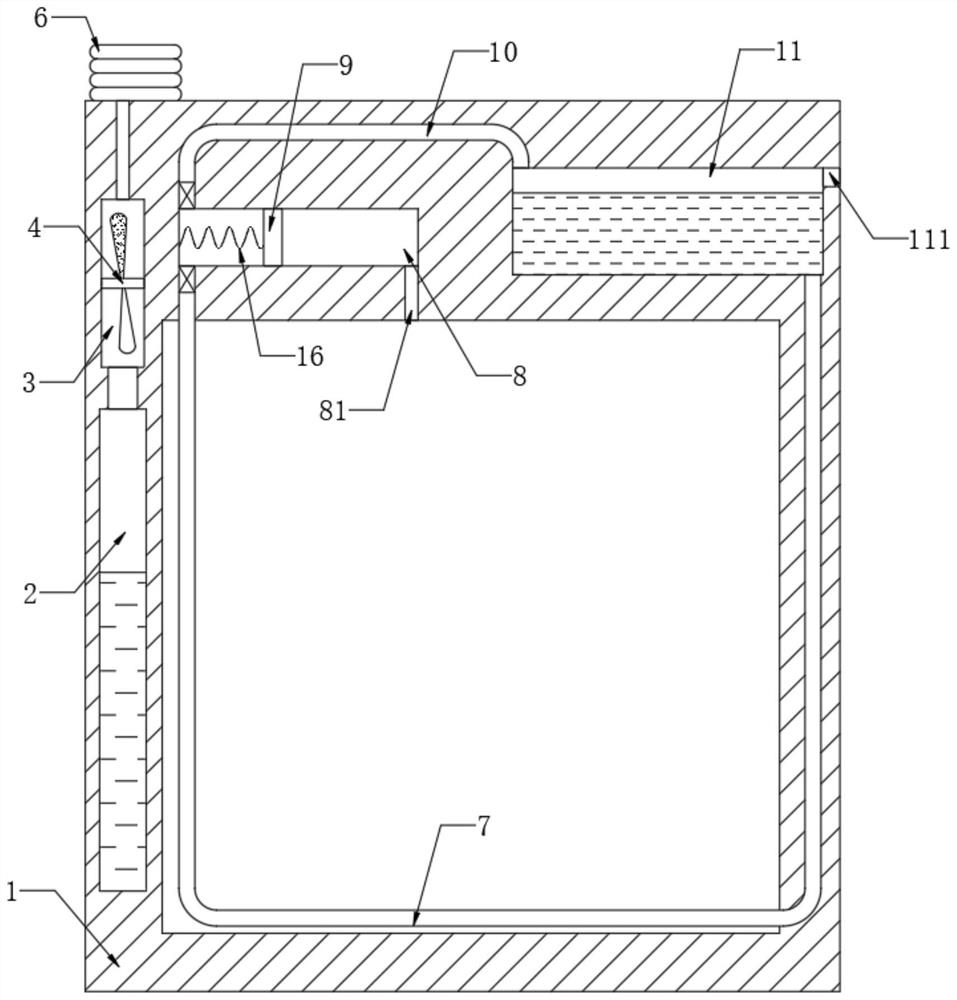

[0020] refer to figure 1 , a fermentation box for flour food processing, comprising a fermentation box 1, a chute 8 is provided on the side wall of the fermentation box 1, a sliding plug 9 is sealed and slidably connected in the chute 8, and the sliding plug 9 is elastically connected by a spring 16 On the inner wall of the chute 8, the side wall of the fermentation box 1 is provided with a first liquid storage tank 11, and the inner wall of the first liquid storage tank 11 is provided with a liquid injection port 111, between the first liquid storage tank 11 and the chute 8 There is a one-way liquid inlet pipe 7 and a one-way liquid return pipe 10 connected between them. The one-way liquid inlet pipe 7 only allows the coolant to flow from the first liquid storage tank 11 to the chute 8, and the one-way liquid return pipe 10 only allows the coolant to To flow from the chute 8 to the first liquid storage tank 11, specifically, a check valve may be installed in the pipeline. A ...

Embodiment 2

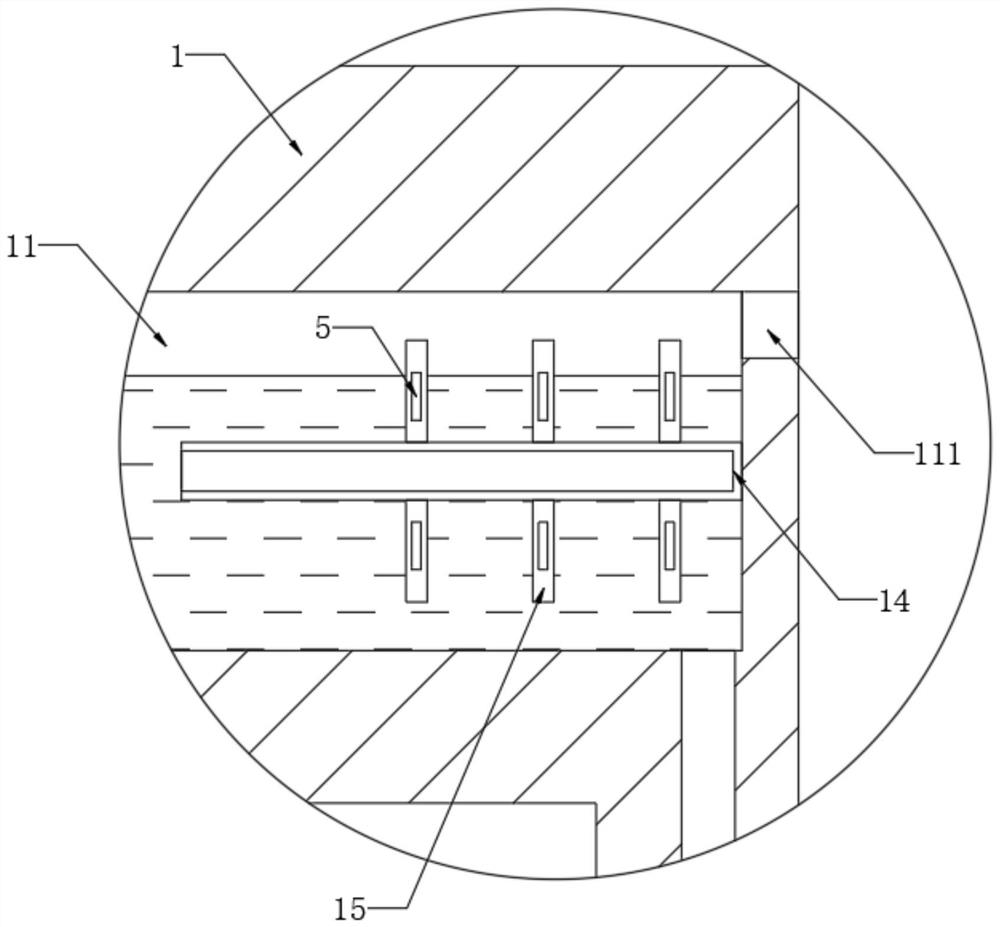

[0025] refer to Figure 2-3 , different from Embodiment 1, a closed coil 12 is embedded on the inner wall of the driving groove 3, a threaded sleeve 14 is rotatably connected to the inner wall of the first liquid storage tank 11, and a multi-threaded sleeve 14 is fixedly connected to the side wall of the threaded sleeve 14. A spoiler vane 15, and a spoiler vane 15 is installed with a semiconductor refrigeration sheet 5, and the semiconductor refrigeration sheet 5 is electrically connected with the closed coil 12, the installation mode of the semiconductor refrigeration sheet 5 and the connection between the closed coil 12 The methods all belong to the existing mature technology, so they will not be described in detail. A screw rod 13 is fixedly connected to the side wall of the slide plug 9 , and the screw rod 13 extends into the first liquid storage tank 11 .

[0026] In this embodiment, during the horizontal back and forth movement of the slide plug 9, the screw rod 13 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com