Air pump electromagnetic valve element sorting system and working method thereof

A sorting system and air pump technology, applied in the direction of analyzing materials, using liquid/vacuum for liquid tightness measurement, and using stable tension/pressure to test material strength, etc. Sorting and other problems, to achieve the effect of efficient and convenient testing, easy sorting, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] see figure 2 as shown,

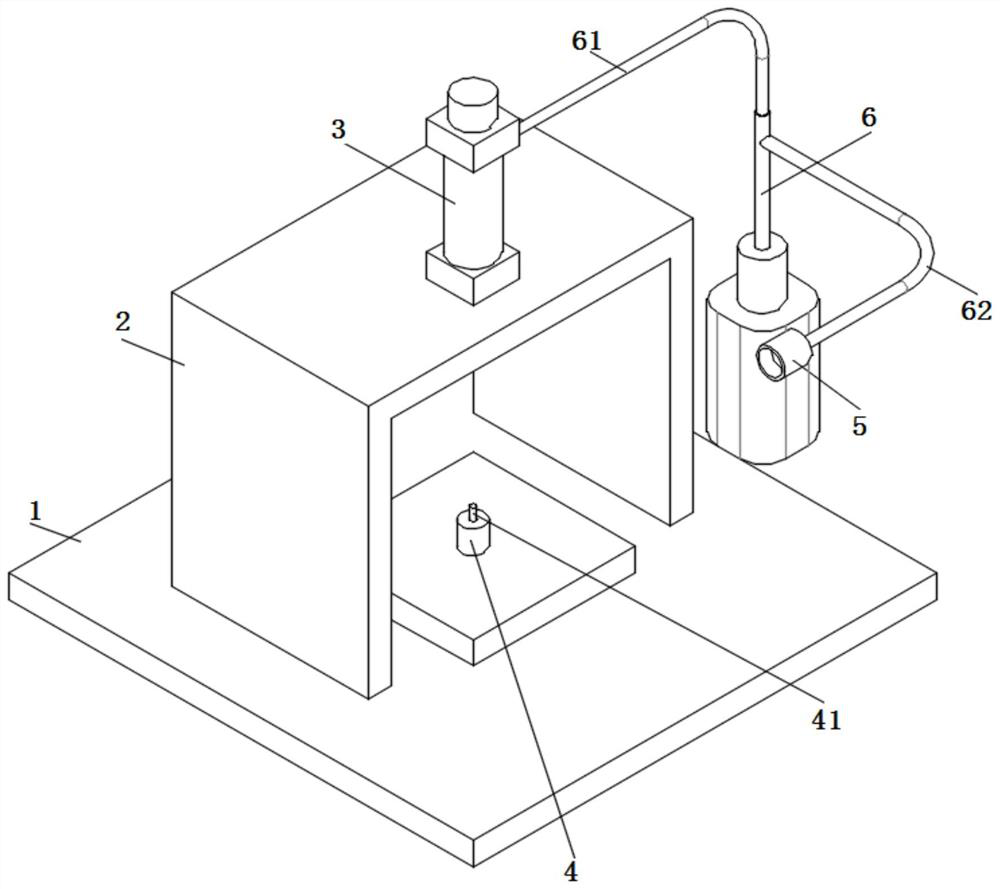

[0041]An air pump solenoid valve core sorting system, comprising: a fixed seat (1), a U-shaped frame (2), a cylinder (3), an air pump solenoid valve (4), a cap (5), and pressurized air source equipment , high-pressure intake valve and controller;

[0042] The air pump electromagnetic valve (4) is arranged on the detection platform on the upper surface of the fixed seat (1); a spool (41) is installed in the air pump electromagnetic valve (4); the cap (5) covers the air pump The solenoid valve (4) is sealed and matched with the air pump solenoid valve (4) to form a high-pressure sealed cavity; the inner wall of the high-pressure sealed cavity is equipped with an air pressure sensor; the inner bottom surface of the cap (5) is matched with the valve core (41); the The U-shaped frame (2) is fixed on the upper surface of the holder (1); the cylinder (3) is fixed on the top of the U-shaped frame (2); the piston of the cylinder (3) passes through the...

Embodiment 2

[0054] As shown in Embodiment 1, the working method of the air pump electromagnetic valve spool sorting system includes the following steps:

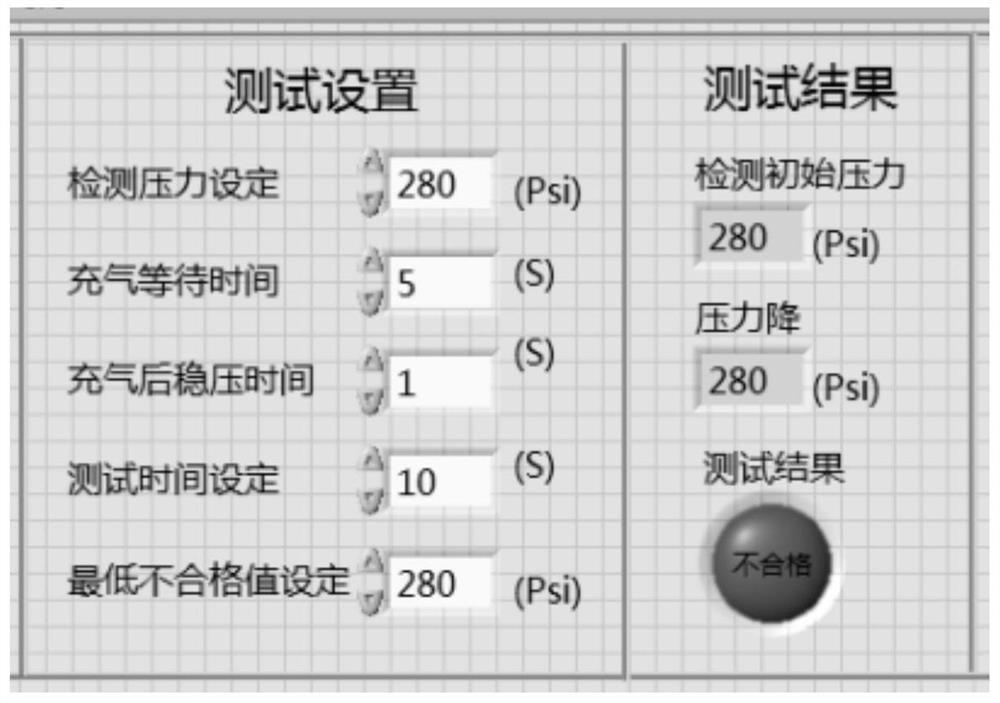

[0055] 1) Set the detection pressure value p through the sorting setting function module of the remote control terminal 1 , inflation waiting time t 1 , voltage stabilization time t after inflation 2 , test time t 3 And the lowest unqualified air pressure value p 2 ; Put the spool to be detected into the air pump solenoid valve (4);

[0056] 2) Select the corresponding cap according to the model of the spool to be tested, and put the cap on the top of the air pump solenoid valve (4), and the cap matches the air pump solenoid valve (4) and the spool; spools with different structures and functions Corresponding caps need to be used for detection; the sorting system of the present invention is provided with multiple different caps to adapt to the detection of various valve cores.

[0057] 3) The controller controls the pressurized air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com