Mechanical rectification mechanism

A technology of mechanical rectification and front cover, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc. It can solve the problems of complex assembly, inability to achieve modular design, low transmission efficiency, etc., and reduce the number of transmission stages , high mechanism transmission efficiency and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

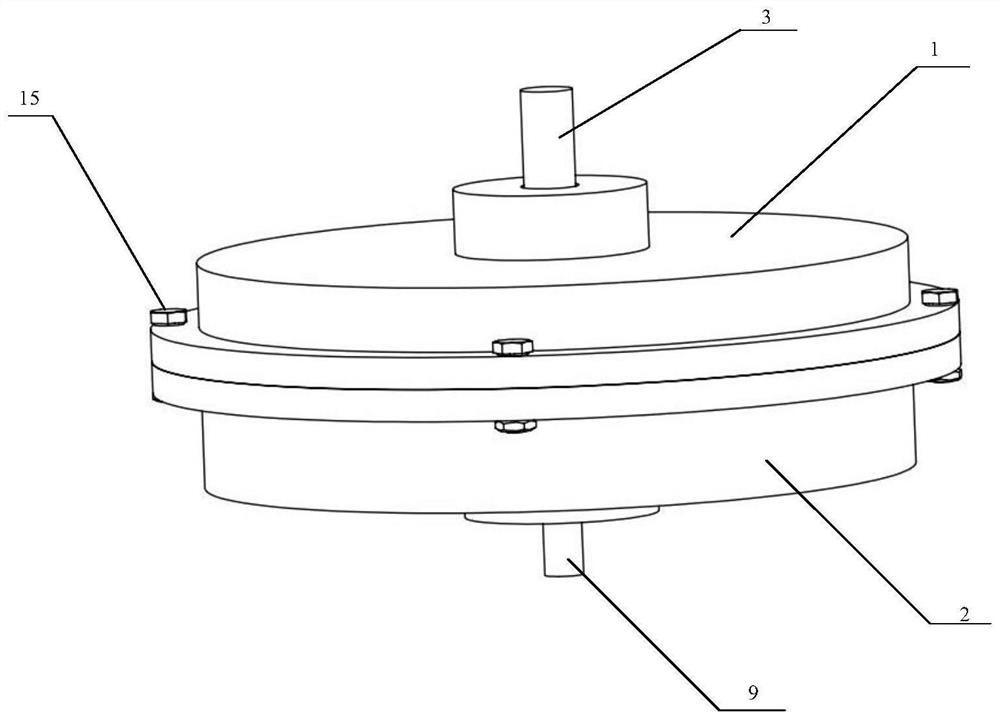

[0021] Such as figure 1 As shown, a compact and efficient mechanical rectification mechanism in this embodiment includes a front cover 1, a rear cover 2, an input shaft 3 and an output shaft 9 in appearance, and four pairs of bolts and nuts 15 are used to package the front cover and the rear cover. Fasten.

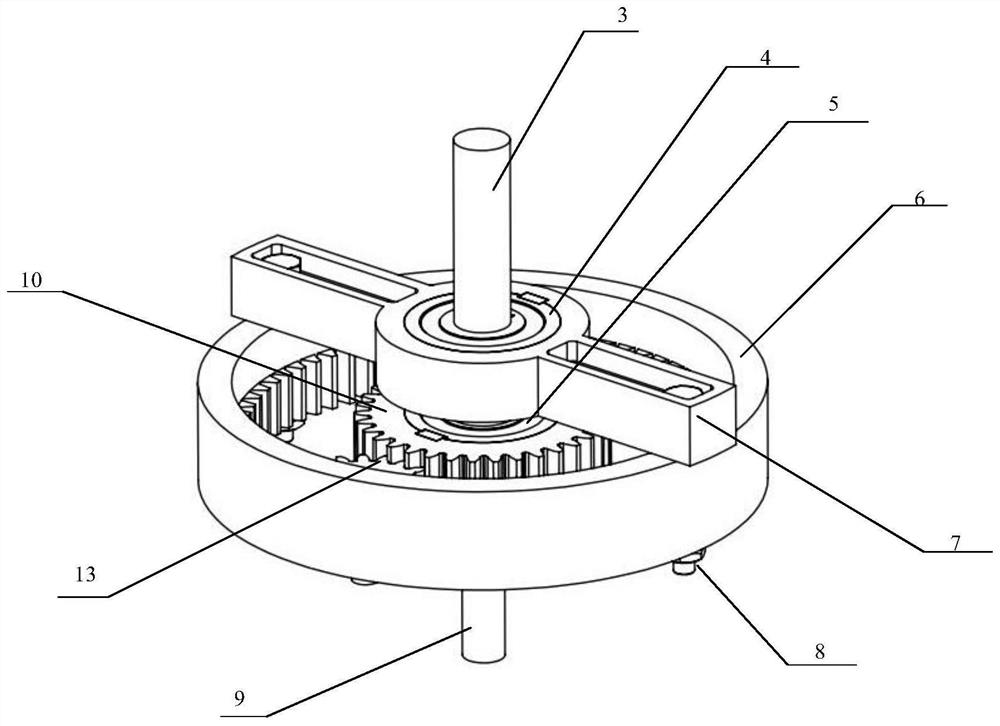

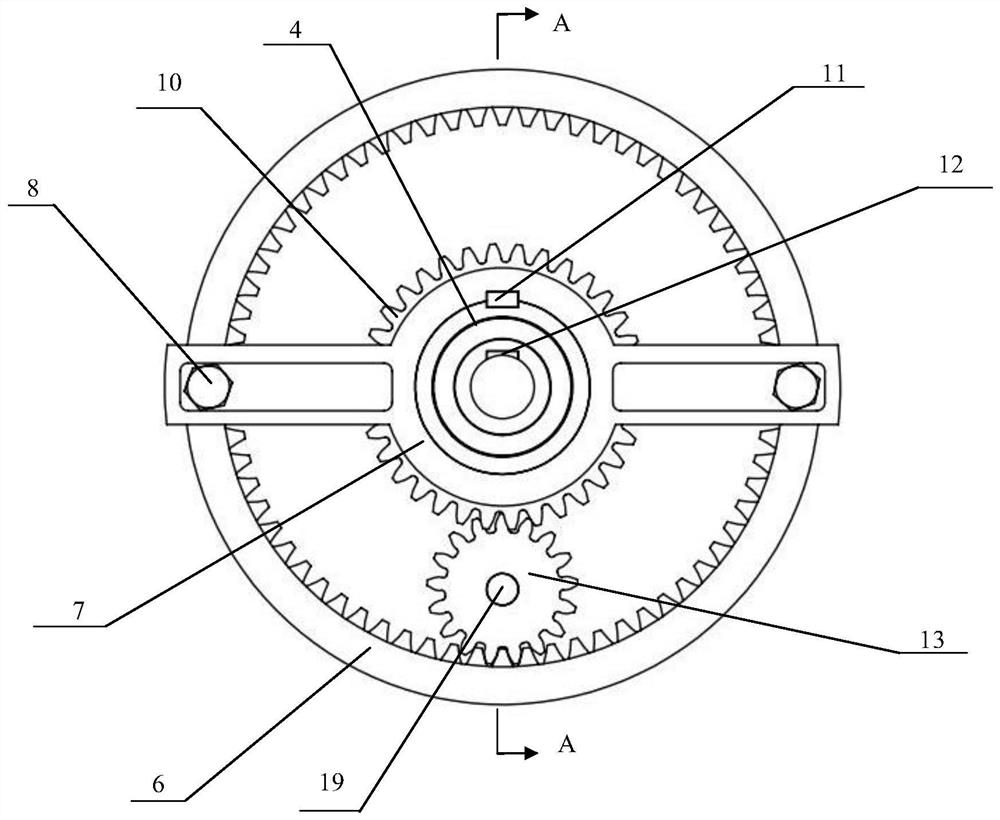

[0022] Transmission system of the present invention such as figure 2 and 3 Shown, be made up of input shaft 3 and output shaft 9, two one-way bearings of 4 and 5, connecting rod 7, ring gear 6, pinion 13 and boss gear 10. In addition, the connection relationship between each component is as Figure 4 shown.

[0023] In this mechanism, the input shaft 3, the connecting rod 7, the boss gear 10 and the output shaft 9 are all coaxial with the rotation center of the entire mechanical rectification mechanism, located in the center of the entire rectification mechanism, and the input shaft 3 is the two ends A stepped shaft with the same diameter and a shoulder at a quarter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com