Spindle mechanical device uniform in transmission

A mechanical device and spindle technology, applied in metal processing equipment, etc., can solve problems such as complicated spindle transmission, influence on machining accuracy, and difficult clamping of lying cars, etc., and achieve the effect of reducing the number of transmission stages, reducing noise pollution, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

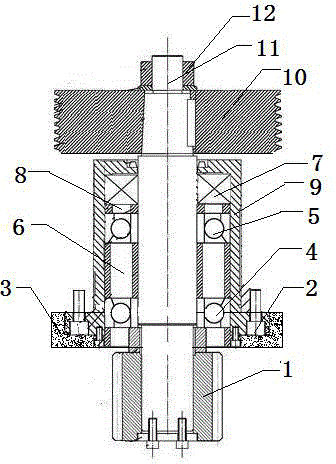

[0012] This embodiment provides a uniform transmission spindle mechanical device, which is characterized in that: the uniform transmission spindle mechanical device includes a shaft sleeve (1), a fixed tool (2), a mounting frame (3), a first deep groove Ball bearing assembly (4), second deep groove ball bearing assembly (5), first block (6), plane bearing assembly (7), second block (8), bearing sleeve (9), gear (10 ), spindle (11), lock nut (12);

[0013] Among them: the shaft sleeve (1) is fixed under the main shaft (11), and the first deep groove ball bearing assembly (4), the second deep groove ball bearing assembly (5) and the plane bearing are sequentially installed on the main shaft (11) Assemblies (7), there are limit blocks between the bearing assemblies and the bearing assemblies, the bearing assemblies (4, 5, 7) are covered with bearing sleeves (9), which are fixed by the mounting frame (3) and the fixed tooling (2), and the main shaft (11) is provided with gear (10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com