Chromium-free passivation composite used for galvanized steel and capable of being dried at medium and low temperatures and preparing and using methods thereof

A technology of low-temperature drying and composition, applied in the direction of metal material coating process, etc., can solve the problems of affecting the adhesion of corrosion-resistant substrates, short drying time, and formation of friction black spot film adhesion, etc., and achieve excellent salt resistance. Fog performance, widely applicable effects

Inactive Publication Date: 2021-02-02

SHANGHAI XINGYU ECOSIL SURFACE MATERIAL

View PDF12 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it has been found in industrial applications in recent years that when these chrome-free passivation solutions are used on production lines with insufficient drying capacity (such as low drying temperature or short drying time), the passivation film cannot be fully dried and cross-linked. Form a dense film, which a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

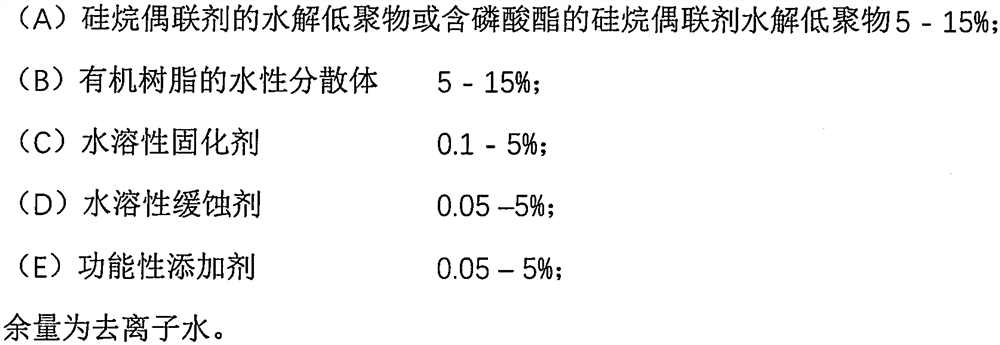

The invention provides a chromium-free passivation composite used for galvanized steel and capable of being dried at medium and low temperatures and preparing and using method thereof. The composite comprises at least one hydrolyzed oligomer dispersion of a silane coupling agent or a hydrolyzed oligomer dispersion of a silane coupling agent containing phosphate, at least one aqueous organic resin,an aqueous curing agent, at least one environment-friendly corrosion inhibitor and at least one functional additive. The chromium-free passivation composite can quickly form a compact film under thecondition of medium-low plate temperature, has excellent corrosion resistance, and can be widely applied to galvanizing production lines under different drying conditions. The invention also disclosespreparing and using methods of the chromium-free passivation composite used for the galvanized steel and capable of being dried at medium and low temperatures.

Description

technical field [0001] The invention relates to a chromium-free passivation composition and its production and use method, in particular to a chromium-free passivation composition used in the production of galvanized coil steel and its production and use method. Background technique [0002] The galvanized layer provides an economical and effective anti-rust method for the steel plate through the protection principle of the sacrificial anode. Galvanized sheet Zinc and zinc alloys are usually applied to steel sheets by a hot-dip process. Commonly used galvanized sheet types include pure zinc sheet (GI), aluminum-zinc sheet (GL), zinc-iron alloy (GA) and zinc-aluminum-magnesium sheet, etc. As an important engineering material, these galvanized sheets are widely used in various fields such as construction, automobile and equipment manufacturing. [0003] Conventional hexavalent chromium (Cr(VI)) passivation treatments provide effective corrosion protection for fresh galvanize...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C22/53

CPCC23C22/53C23C2222/20

Inventor 陆海涛朱洪帆朱丹青俞威曾建峰

Owner SHANGHAI XINGYU ECOSIL SURFACE MATERIAL

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com