High-speed and high-precision single-bundle fiber impregnation machine

A high-precision, fibrous technology, applied in the direction of thin material processing, coating, and conveying filamentous materials, can solve the problems of insufficient dipping amount, lower dipping quality, uneven glue amount, etc., and achieve the goal of increasing production and The quality of dipping, reducing the amount of resin adhesion, and the effect of high-precision impregnation and gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

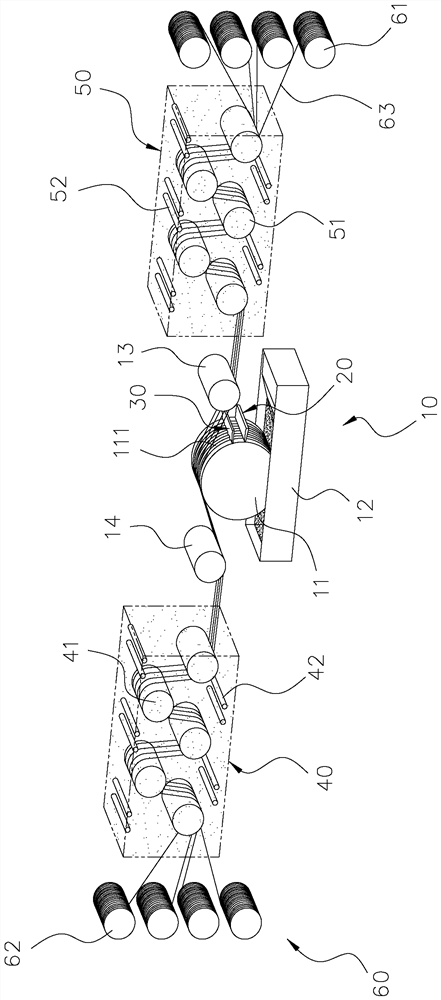

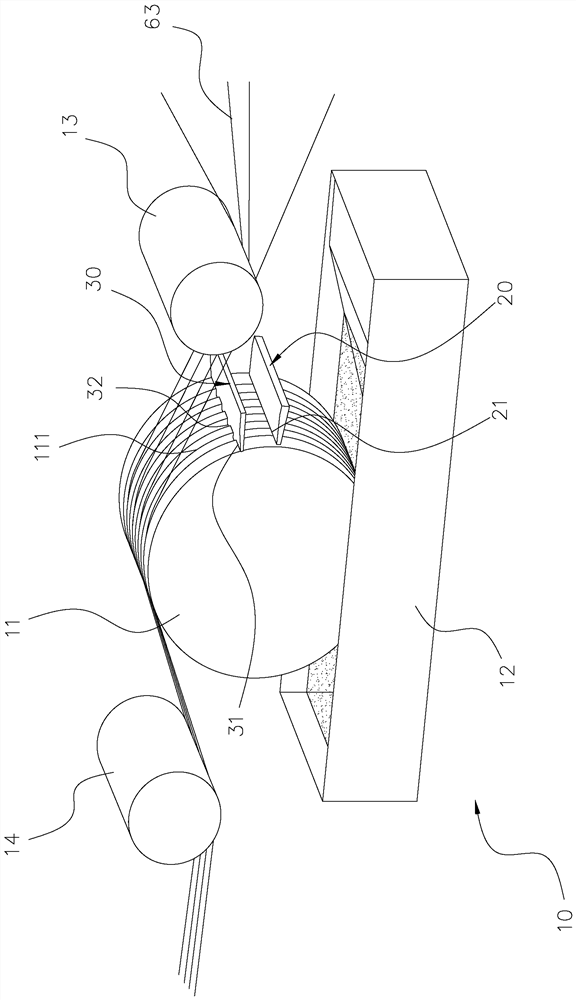

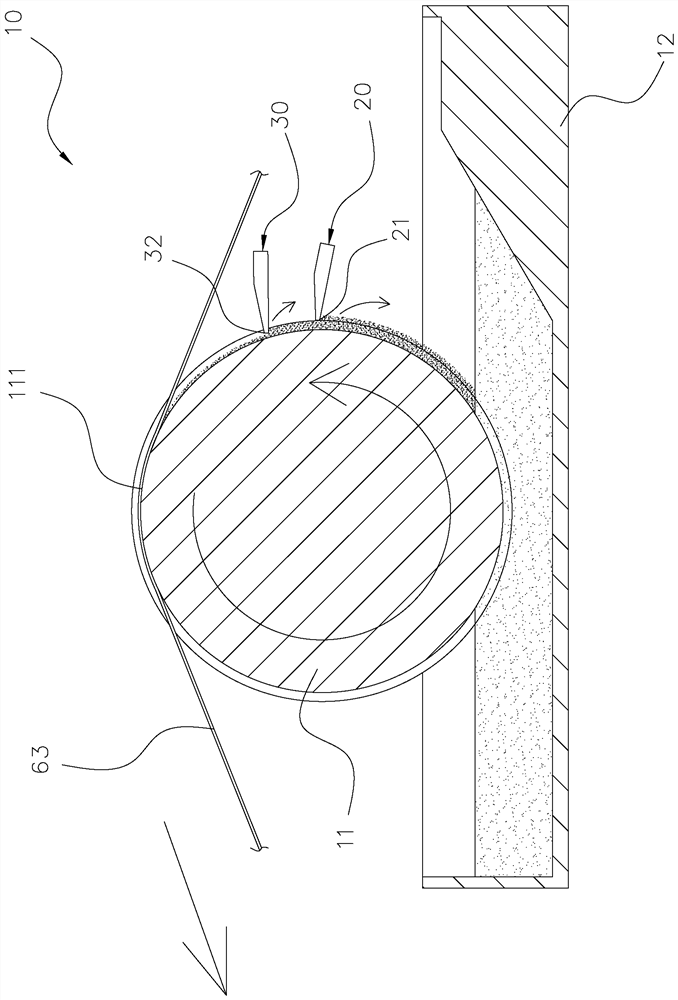

[0036] please first figure 1 continuous to image 3As shown, a high-speed and high-precision single-bundle fiber impregnation machine includes: an impregnation wheel set 10, a first scraper 20, a second scraper 30, a soaking heating box 40, a fiber heating box 50 and A fiber winding wheel set 60, an impregnation wheel set 10 includes an impregnation roller 11, a resin tank 12, a front guide wheel 13 and a rear guide wheel 14. The surface of the impregnation roller 11 is concave with a plurality of yarn guiding grooves 111, the above-mentioned yarn guiding grooves 111 are arranged in the same circumference and depth along the axis of the impregnating roller 11, and the front guiding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com