Method for manufacturing diisocyanate and optical lens

A kind of technology of diisocyanate and m-xylylene diisocyanate, applied in the field of preparing diisocyanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

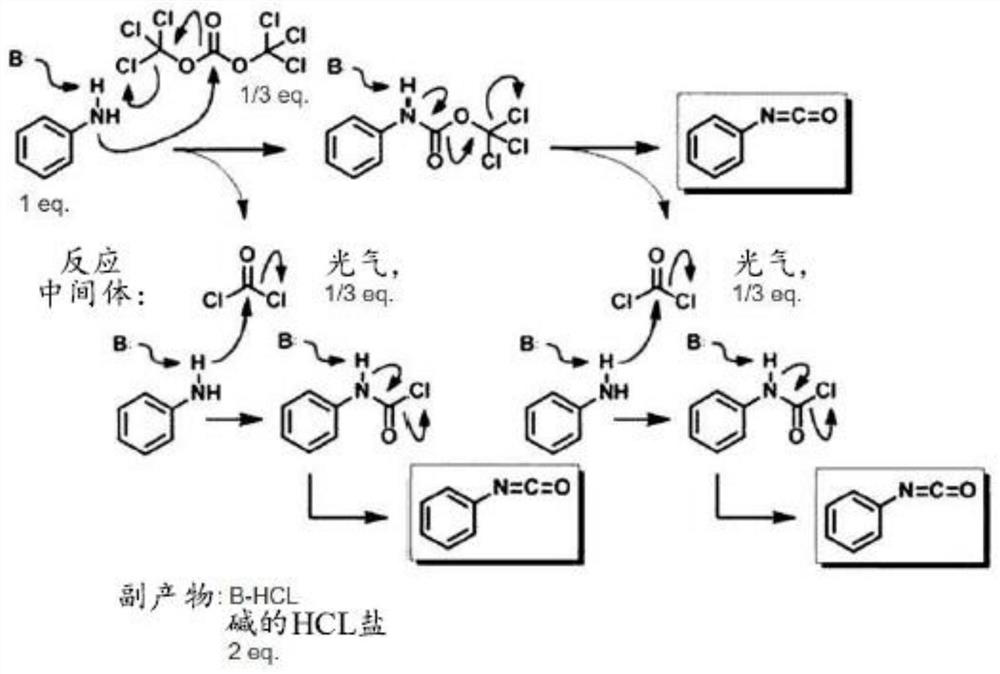

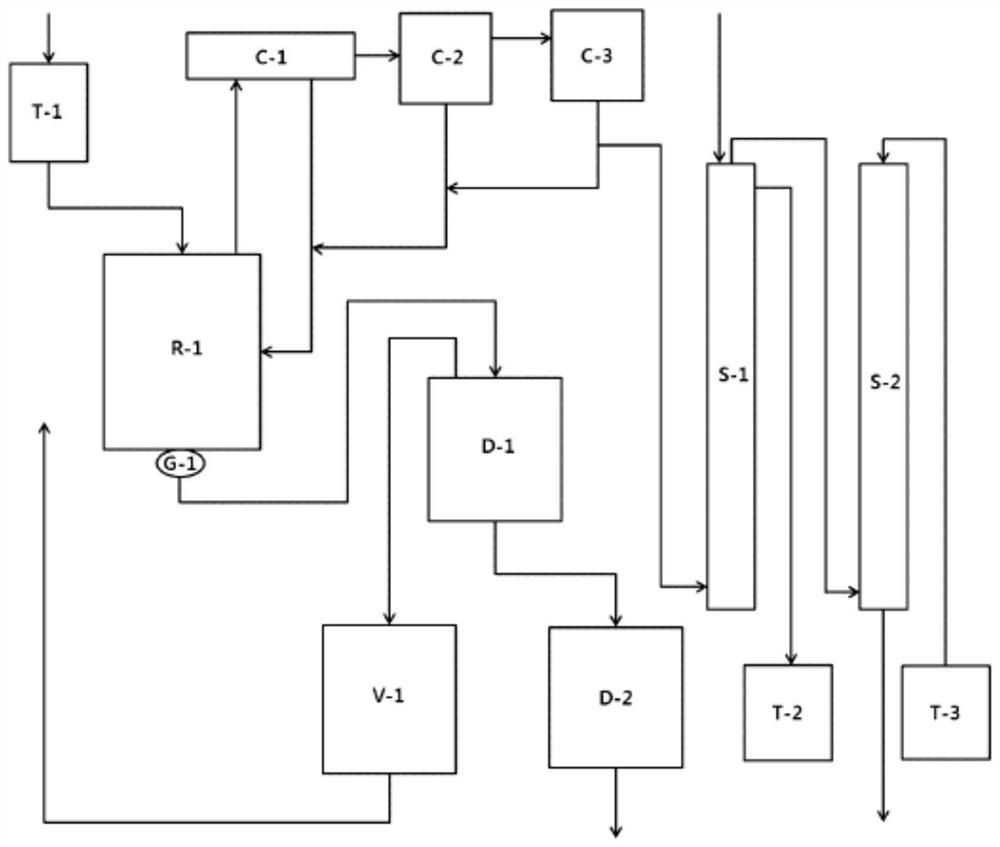

Method used

Image

Examples

preparation example Construction

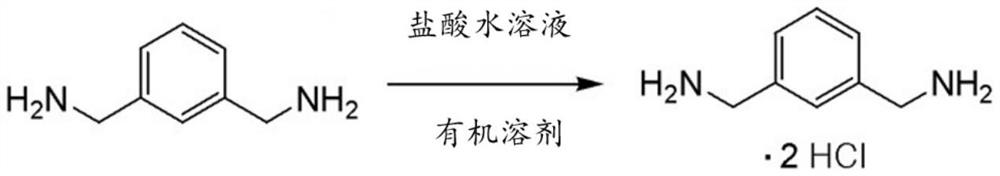

[0033] A method for preparing a diisocyanate according to an embodiment includes preparing at least one diamine selected from the group consisting of o-xylylenediamine, m-xylylenediamine, p-xylylenediamine, norbornenediamine, hydrogenated benzene Dimethylamine, and isophorone diamine; making said diamine react with aqueous hydrochloric acid in a first solvent to obtain diamine hydrochloride; and making said diamine hydrochloride and triphosgene react in a second Reaction in organic solvents to obtain diisocyanates.

[0034]In the method for preparing diisocyanate according to the embodiment, the diamine used as a raw material may be at least one selected from the group consisting of o-xylylenediamine (o-XDA), m-xylylenediamine (m- XDA), p-xylylenediamine (p-XDA), norbornenediamine (NBDA), hydrogenated xylylenediamine (H6XDA), and isophoronediamine (IPDA).

[0035] Preparation of diamine hydrochloride

[0036] First, diamine is reacted with aqueous hydrochloric acid in a firs...

specific Embodiment approach

[0177] Hereinafter, more specific embodiments are shown, but the present invention is not limited thereto.

[0178]

example 1

[0180] Into a 5-liter 4-neck reactor was charged 963.5 g (9.25 mol) of 35% aqueous hydrochloric acid, and then the internal temperature of the reactor was lowered to 15°C to 20°C while stirring. While maintaining the temperature of the reactor at 25°C to 50°C, 600.0 g (4.4 moles) of m-xylylenediamine (m-XDA) was introduced for 1 hour. After the introduction was completed, the internal temperature of the reactor was lowered to 10°C to 20°C, and it was stirred for 1 hour. Thereafter, 1,200.0 g of diethyl ether (Et 2 O) as an organic solvent, and lower the internal temperature of the reactor to -5°C to 0°C, and then stir for 30 minutes to 1 hour. After the reaction was completed, it was vacuum filtered using a filter, and the filtered diethyl ether was recovered for reuse. The recovery of diethyl ether was 73%. After vacuum filtration, m-xylylenediamine (m-XDA) hydrochloride was obtained. In order to remove the residual organic solvent and water, drying was carried out under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com