A hydrogen fuel cell power system, chopper circuit control system and method

A chopper circuit and control system technology, applied in control/regulation systems, electrical components, and adjustment of electrical variables, can solve problems such as excessive ripple current, improve circuit efficiency, improve EMI problems, and solve excessive ripple current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

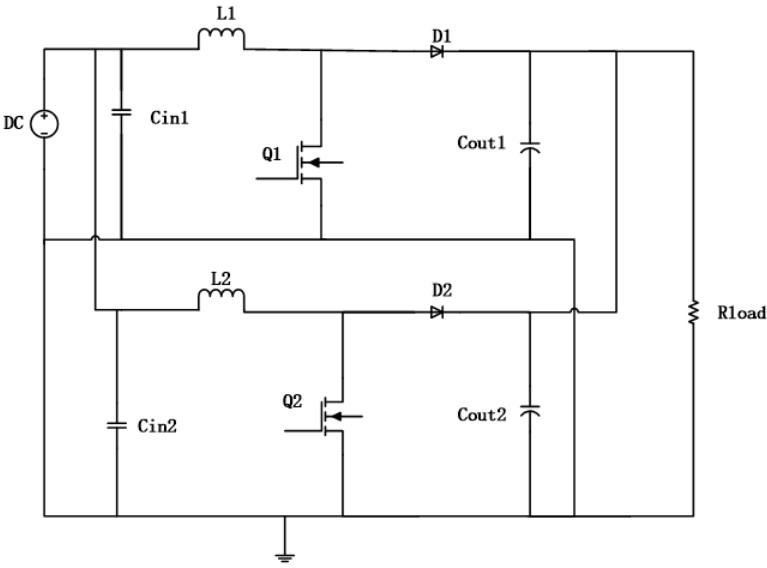

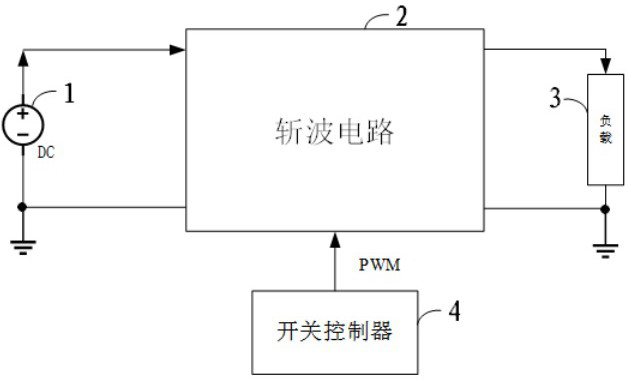

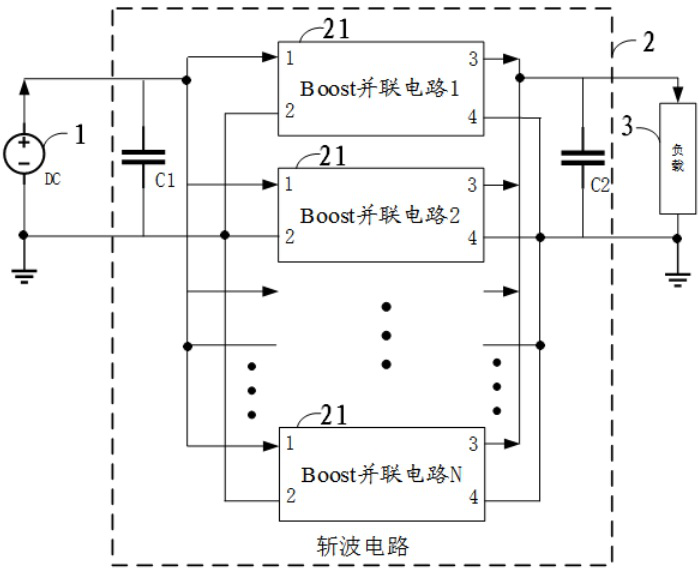

[0039] Please refer to figure 2 , is a schematic diagram of the structural connection of the chopper circuit control system in an embodiment, including a DC power supply 1 , a load 3 , a chopper circuit 2 and a switch controller 4 . The chopper circuit control system is used to convert the first DC power supply into the output of the second DC power supply, and the chopper circuit control system includes a chopper circuit 2 and a switch controller 4 . Please refer to image 3 , is a schematic diagram of the structural connection of the chopper circuit in an embodiment, the chopper circuit 2 includes at least one set of Boost parallel circuits 21 . Please refer to Figure 4 , is a schematic diagram of the structural connection of the Boost parallel circuit in an embodiment, the Boost parallel circuit 21 includes two magnetically coupled Boost circuits 211 connected in parallel, as Figure 4 Boost circuit 1 and Boost circuit 2 are shown. Each Boost circuit 211 includes a fi...

Embodiment 2

[0046] Please refer to Figure 6 , which is a flowchart of a chopper circuit control method in another embodiment, including:

[0047] Step 100, controlling the wave sending sequence of the chopper circuit.

[0048] The wave transmission timing of the two Boost circuits controlling each group of Boost parallel circuits is out of phase by 180 degrees. Wherein, the chopper circuit includes at least one set of Boost parallel circuits, and the Boost parallel circuit includes two magnetically coupled Boost circuits connected in parallel.

[0049] In one embodiment, the chopper circuit control method further includes:

[0050] Step 200, controlling the working mode of the chopper circuit.

[0051] The control chopper circuit works in CCM mode.

[0052] In one embodiment, the chopper circuit includes N sets of Boost parallel circuits, where N is an integer greater than 2. The chopper circuit control method also includes:

[0053] Step 300, controlling the timing of sending wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com