Small-hole gravity type solder ball array method and process

A gravity type and solder ball technology, which is applied in the field of small hole gravity type solder ball arrays, can solve the problems of low production capacity and poor precision, and achieve the effects of increasing production capacity, improving processing efficiency, and increasing implantation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

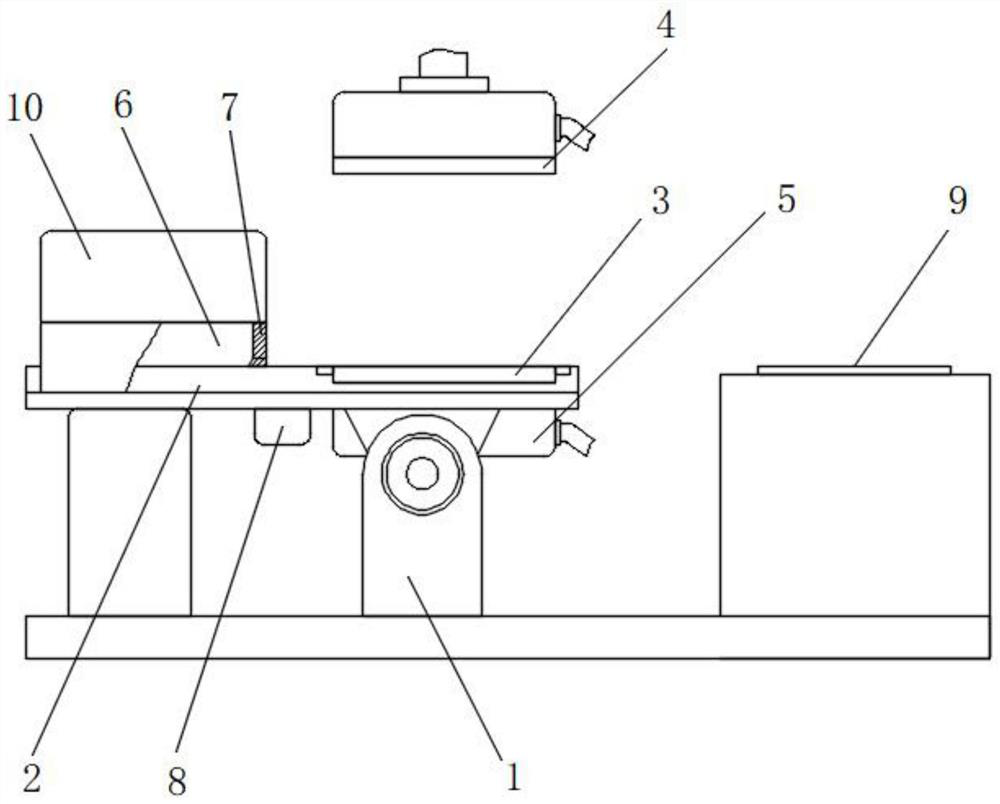

[0028] The present invention provides such as Figure 1-4 A small hole gravity solder ball array method and process shown includes the following steps:

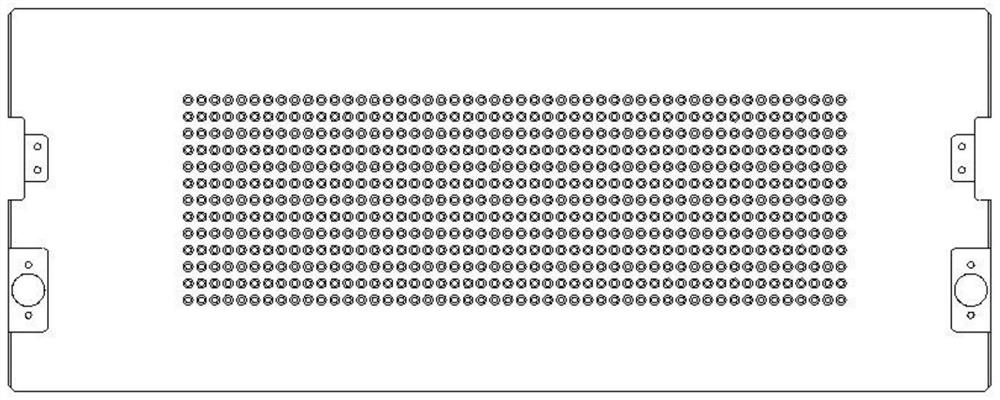

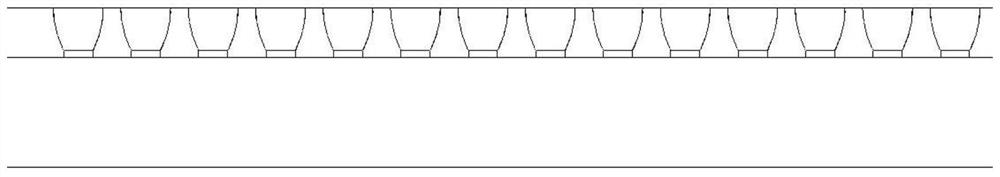

[0029] Step 1. Set the lower solder ball plate 3 on the operating platform 2 that can be tilted and turned over, and set the ball fetching upper plate 4 that can move left and right and up and down above the solder ball lower ball plate 3. Arrayed cup-shaped micro-holes are processed in the ball plate 4 and the solder ball lower ball plate 3, and the cup-shaped micro-holes on the ball upper plate 4 correspond to the cup-shaped micro-holes on the solder ball lower ball plate 3;

[0030] Step 2: Install a vacuum cavity support plate 5 on the bottom of the lower ball plate 3 for solder balls and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com