Apparatus for automated assembly and routing of electrical apparatuses

An electrical equipment and wiring technology, applied in the field of automatic assembly and wiring equipment, can solve the problems of affecting the appearance, troublesome inspection and maintenance, troublesome wiring method, etc., and achieve the effect of beautiful appearance, reasonable structure design and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

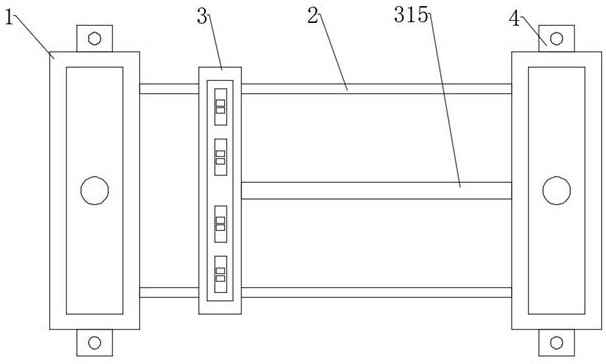

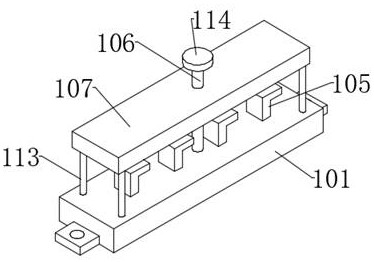

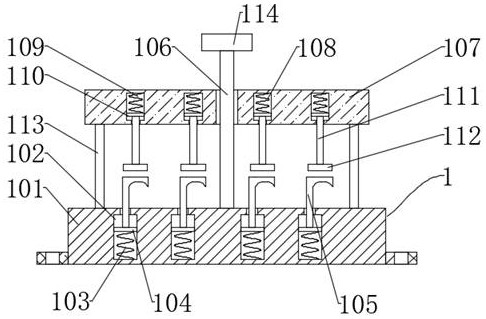

[0027] like Figure 1-5 As shown, the embodiment of the present invention provides equipment for automatic assembly and wiring of electrical equipment, including a wire crimping device 1 for pressing and fixing the power cord. The number of the wire crimping devices 1 is set to two, and two A sliding rod 2 is fixedly connected between the wire pressing devices 1. The wire pressing device 1 includes a base 101. A first pressing groove 102 is opened inside the base 101, and a first pressing groove is fixedly connected to the inner bottom of the first pressing groove 102. The spring 103 is used to eject the clamping rod 105 from the first extrusion groove 102, so as to facilitate the removal of the power cord. A squeeze groove 102 falls off, the upper surface of the first limiting plate 104 is fixedly connected with a clamping rod 105, the clamping rod 105 is an L-shaped rod, and both the clamping rod 105 and the first limiting plate 104 are slidably connected with the base 101, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com