Flexible workshop scheduling optimization method and system considering crane transportation process

A technology for workshop scheduling and transportation process, applied in control/adjustment system, general control system, program control, etc., to achieve the effect of reducing the maximum completion time and total energy consumption, and improving the efficiency of processing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

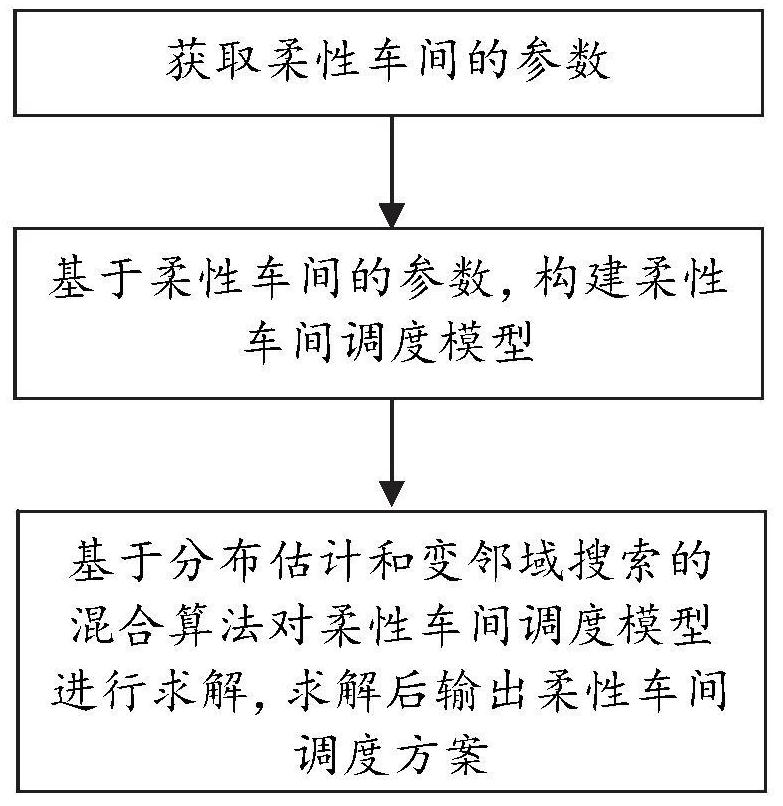

[0053] This embodiment provides a flexible workshop scheduling optimization method considering the crane transportation process, such as figure 1 shown, including:

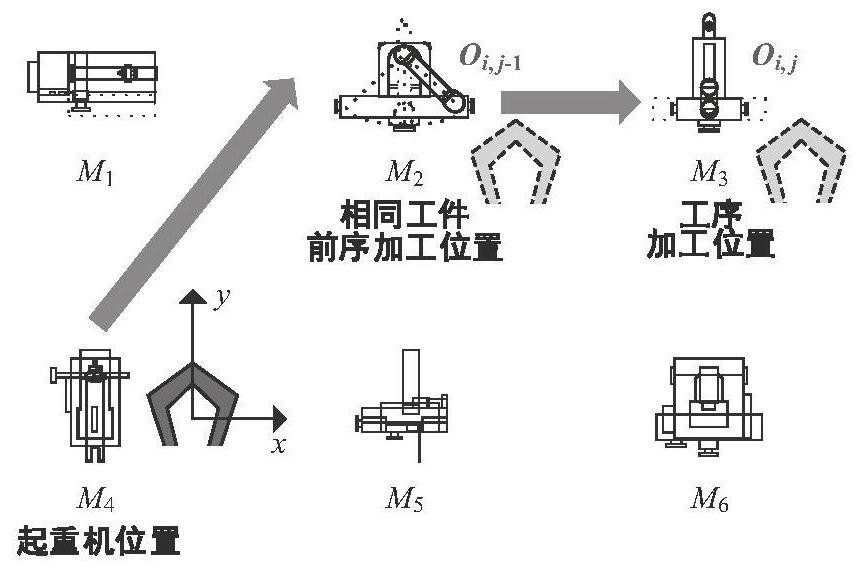

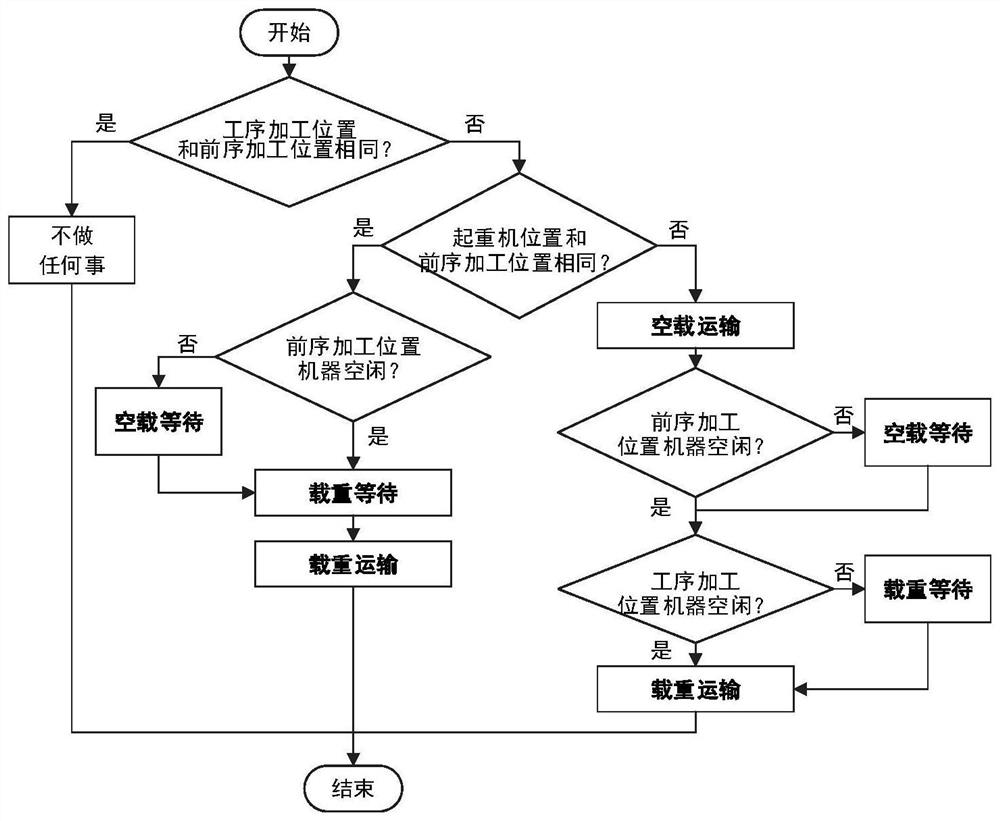

[0054] Obtain the parameters of the flexible workshop, the parameters include the number of machines in the target factory, the number of workpieces, the processing procedure corresponding to each workpiece, the processing machine corresponding to each procedure, the processing time of the workpiece, and the position coordinates of the crane;

[0055] Based on the parameters of the flexible workshop, a flexible workshop scheduling model is constructed; the flexible workshop scheduling model aims at minimizing the maximum completion time and total energy consumption;

[0056] The hybrid algorithm based on distribution estimation and variable neighborhood search solves the flexible shop-shop scheduling model, and outputs the flexible shop-shop scheduling scheme after solving; among them, all individual solutions in ...

Embodiment 2

[0195]In this embodiment, the hybrid algorithm described in Embodiment 1 is subjected to experimental analysis to evaluate its performance. The algorithm and other comparative algorithms are implemented in C++ and run on an Intel Core i7 2.6-GHz 8GB memory computer. The comparison algorithms include Girish and PSO algorithm, VNS algorithm, GA algorithm and IG algorithm.

[0196] In order to compare the performance of the algorithm and other algorithms, the following performance index of relative percentage increase (RPI) is proposed:

[0197]

[0198] where f c is the average fitness value of the given algorithm, f b is f in all comparison algorithms c the optimal value of .

[0199] This embodiment includes four types of calculation examples. The first type of calculation example is a small-scale calculation example, where the number of workpieces is I={7,9,10}, and the number of machines M=6. The second type of calculation examples are medium-scale calculation examp...

Embodiment 3

[0232] This embodiment provides a flexible workshop scheduling optimization system considering the crane transportation process, including:

[0233] The parameter acquisition module is configured to: acquire the parameters of the flexible workshop, the parameters include the number of machines in the target factory, the number of workpieces, the processing procedure corresponding to each workpiece, the processing machine corresponding to each procedure, the processing time of the workpiece, the crane location coordinates;

[0234] The flexible workshop scheduling model building module is configured to: build a flexible workshop scheduling model based on the parameters of the flexible workshop; the flexible workshop scheduling model aims at the maximum completion time and the minimization of total energy consumption;

[0235]The scheduling scheme output module is configured to: solve the flexible workshop scheduling model based on the hybrid algorithm of distribution estimation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com