Model supporting device applied to wind tunnel test

A technology of wind tunnel test and support device, which is used in measurement device, aerodynamic test, machine/structural component test, etc. The effect of reasonable strength of support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The implementation process of this embodiment is as follows:

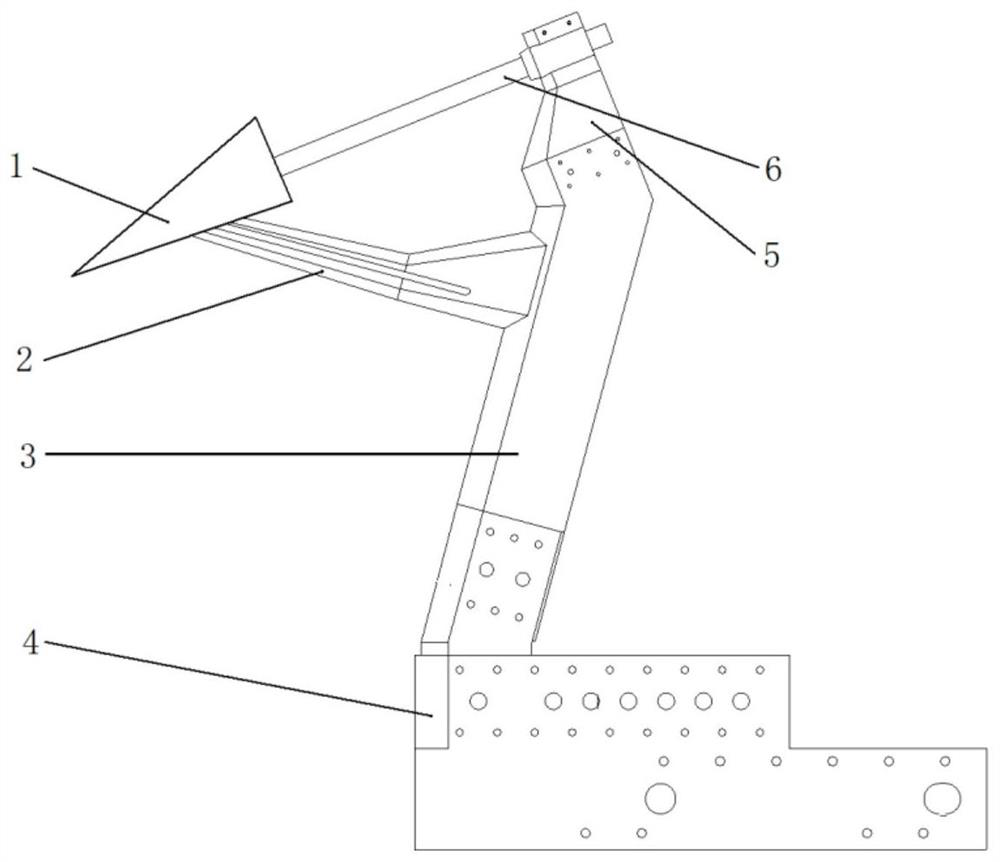

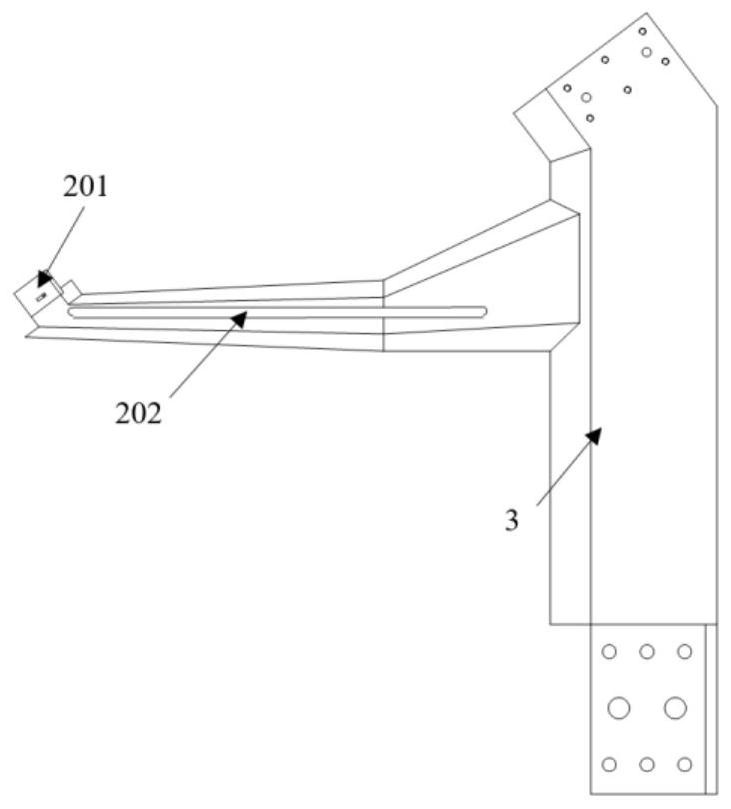

[0050] a. According to figure 1 Install the "back support + false tail strut + modified nozzle" test device, and conduct a hypersonic wind tunnel test;

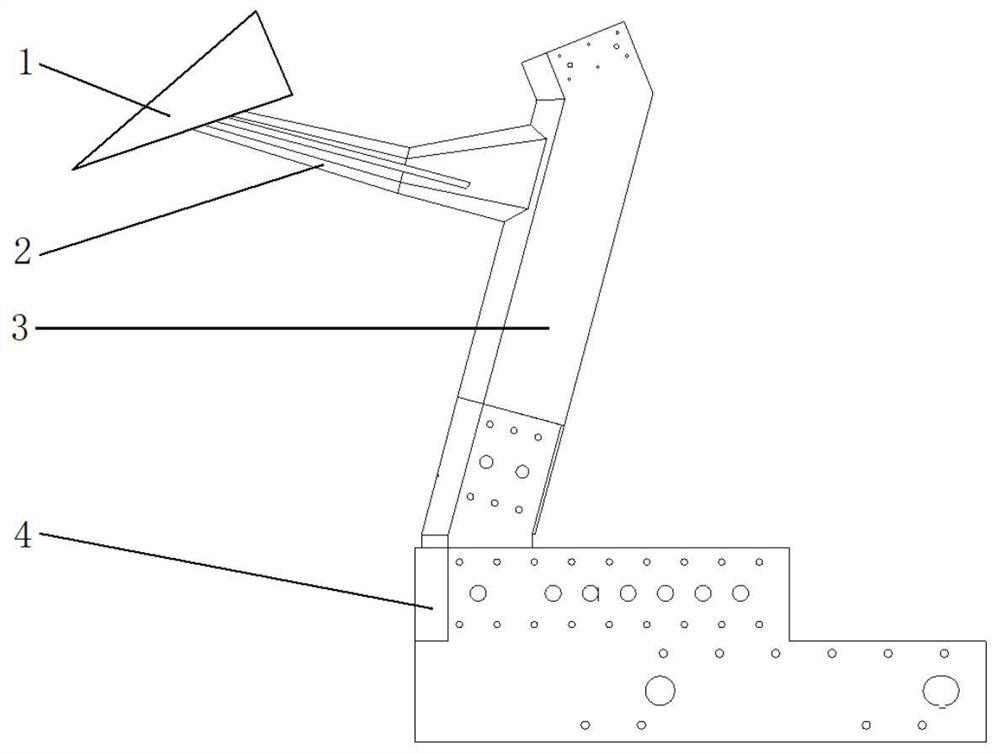

[0051] b. Demolition figure 1 The false tail strut support 5 and the false tail strut 6 in the model 1 are replaced with the real nozzle at the same time, and the obtained figure 2 The "back support + real nozzle" test device shown, and the hypersonic wind tunnel test was carried out;

[0052] c. Demolition figure 2 Replace the "tail support + repair nozzle" test device, and conduct a hypersonic wind tunnel test;

[0053] d. Perform data processing on the test results obtained in steps a, b, and c, and deduct the influences of "back support interference" and "nozzle modification + tail support interference" to obtain the aerodynamic force of model 1 of the real profile nozzle .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com