A T-shaped cross-beam cross island membrane pressure sensor chip and its preparation method

A pressure sensor, cross beam technology, used in the measurement of fluid pressure, fluid pressure measurement by changing ohmic resistance, instruments, etc., can solve the problem that the corrugated sheet is not resistant to corrosion, hysteresis, and the operating temperature of the oil-filled package cannot be higher than 200 ℃ and other problems, to achieve the effect of low cost, reasonable structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

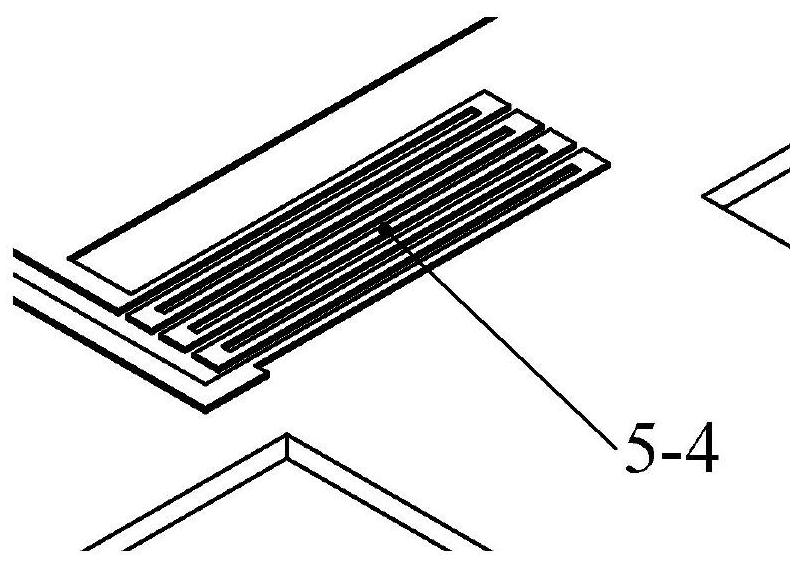

[0046] Referring to Fig. 1(a), Fig. 1(b), Fig. 1(c), Fig. 1(d), figure 2 , a T-shaped cross-beam cross-island membrane pressure sensor chip, including a substrate 1, a film 2 is arranged in the middle of the front of the substrate 1, and a T-shaped cross beam 3 is connected to the upper surface of the film 2, and the T-shaped cross beam 3 is composed of four same-sized It is composed of T-beams, the narrow ends of the T-beams are connected at the tail, and the adjacent T-beams are vertical so that the T-shaped cross beams 3 are axisymmetrically distributed on the film 2, and the wide ends of the four T-beams are connected to the base 1 ; In the etching cavity on the back of the substrate 1, a cross-shaped mass 4 is attached to the center of the lower surface of the film 2, and the cross-shaped mass 4 corresponds to the T-shaped cross beam 3 up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com