Barrel type efficient impact drill bit for rock-socketed inclined pile construction

An impact drill bit and inclined pile technology is applied in the field of cylindrical high-efficiency impact drill bits for rock-socketed inclined pile construction, which can solve the problems of repeated rock breaking by the drill bit, low impact hole forming efficiency, uncontrolled rotation direction and angle, etc. Service life, keep the bottom of the hole clean, ensure the effect of uniform wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described The embodiments are only some of the embodiments of the present application, but not all of them.

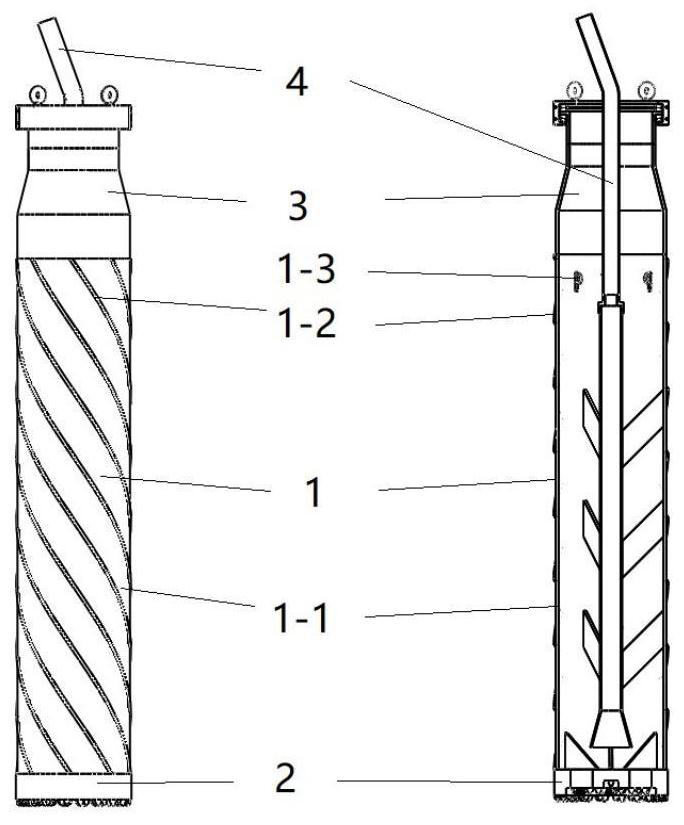

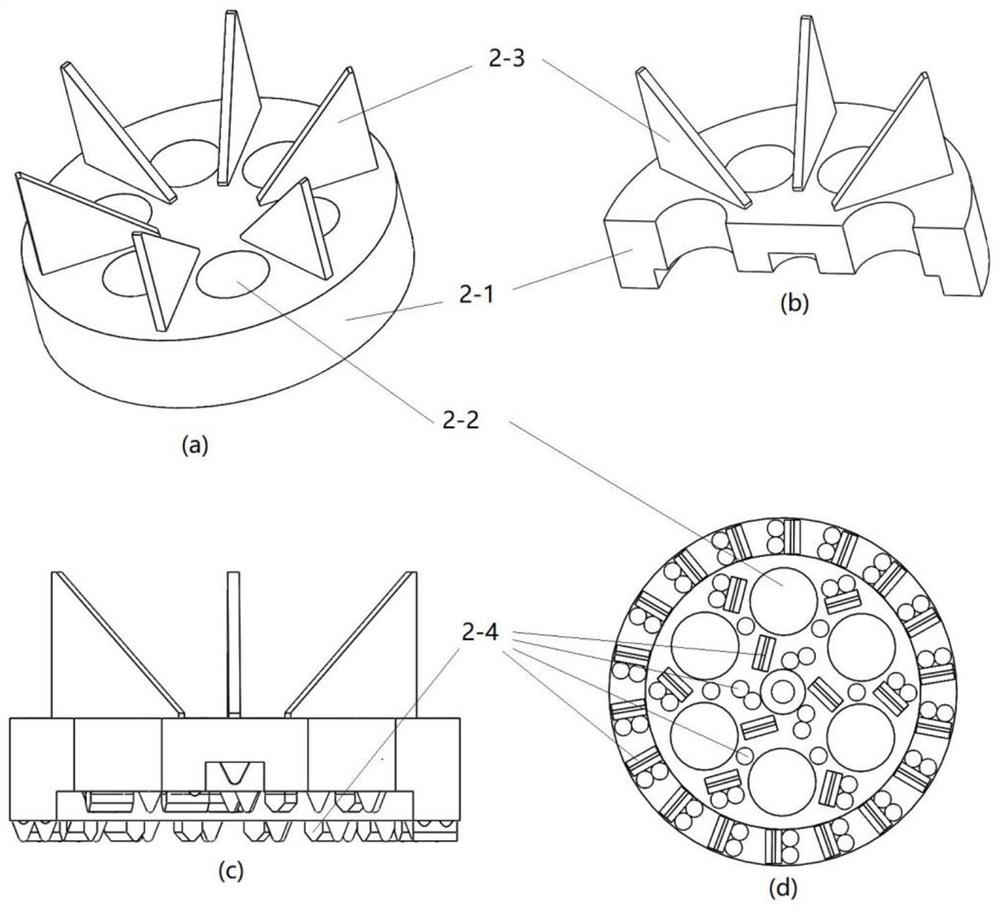

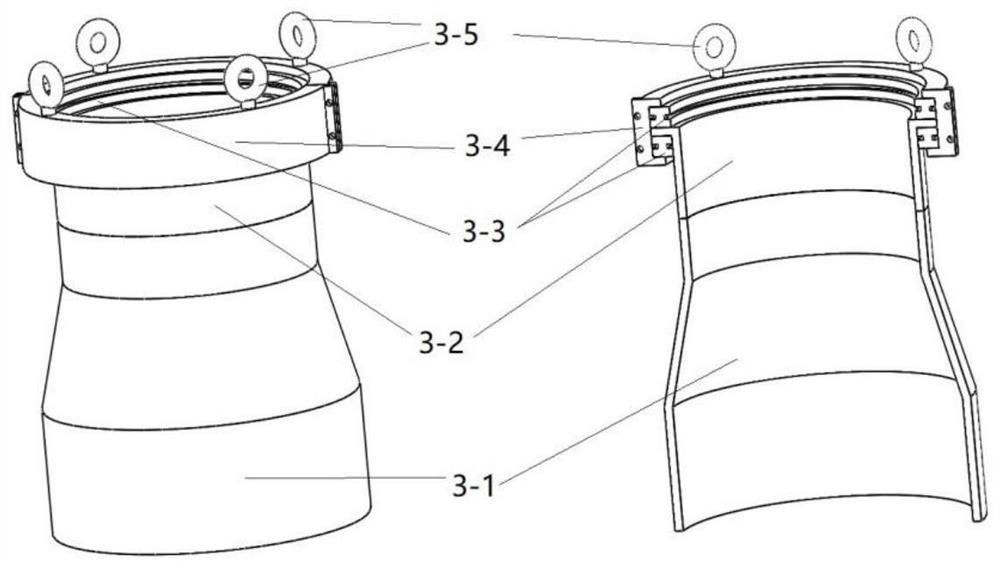

[0053] refer to figure 1 , figure 1It is a structural schematic diagram of a cylindrical high-efficiency percussion drill bit for rock-socketed inclined pile construction provided by an embodiment of the present invention. In this embodiment, the cylindrical high-efficiency percussion drill bit for rock-socketed inclined pile construction includes: a circular drill cylinder body 1 , a gear holder 2 , a single-action device 3 and a reverse circulation slag discharge device 4 .

[0054] In this embodiment, the circular drill cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com