Double-thread steel column head connection type steel rib floor support plate-beam-column system and using method thereof

A technology of threaded steel and floor deck, which is applied in the field of double threaded steel column head connection type steel reinforced floor deck-beam-column system, can solve the problems of poor connection performance, large thickness of reinforced concrete floor, weak anti-slip performance, etc. , to achieve the effect of improved integrity and stability, small amount of concrete poured in place, and high connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In conjunction with accompanying drawing, the concrete implementation process of the present invention is described in detail:

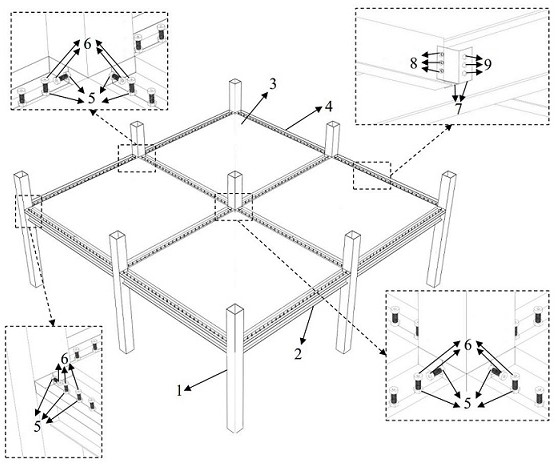

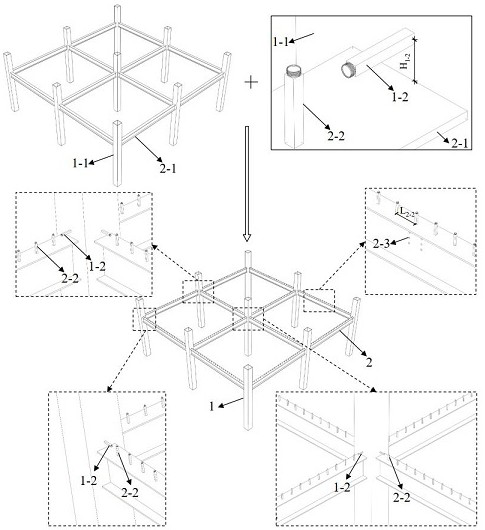

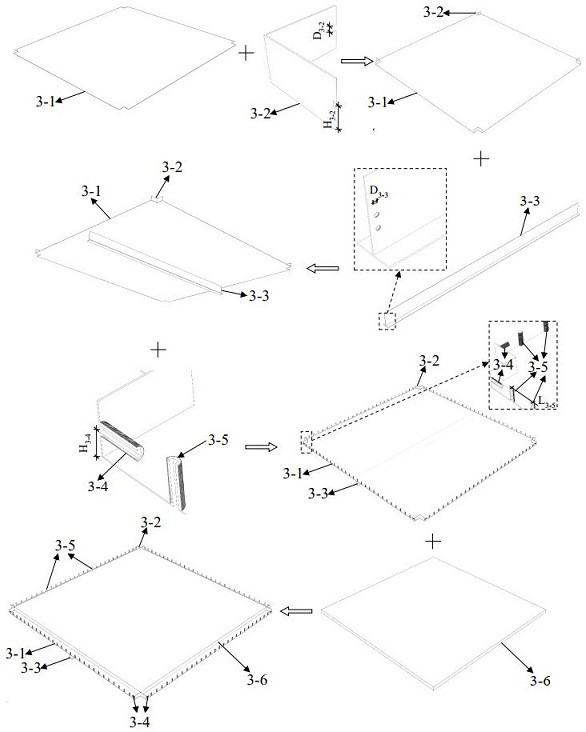

[0046] Such as Figure 1~9 As shown, the present invention is a double-threaded steel column head connected steel frame floor deck-beam-column system, including a steel pipe column with an inner threaded steel column head, a steel beam with an inner threaded steel column head 2, and a half-wrapped threaded steel column with an outer ring. Steel frame composite floor deck at the bottom of the steel column head 3. Outer steel formwork with outer threaded half-clad steel column head 4. Fixed outer ring threaded steel column head large hexagonal nut 5. Fixed inner and outer ring threaded steel column head cylindrical nut 6. Hinged Connecting plate 7, connecting steel frame and hinged connecting plate bolt group 8, connecting hinged connecting plate and steel beam bolt group 9;

[0047] Such as figure 1 As shown, the steel pipe column 1 with inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com