Method for preparing mine filling by cementing heavy metal tailings with solid waste in iron and steel industry

A solid waste and mine filling technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of low comprehensive utilization rate, environmental pollution, occupying land resources, etc., to achieve low prices and reduce production Cost, the effect of abundant sources

Active Publication Date: 2022-05-31

CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

View PDF18 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Desulfurization ash is an industrial solid waste produced by semi-dry flue gas desulfurization technology in the iron and steel industry. The main component is calcium sulfite (CaSO 3 ), calcium sulfate (CaSO 4 ), calcium sulfate hemihydrate (CaSO 4 0.5H 2 O) and ammonium salts, etc., CaSO 3 Easily oxidized to calcium sulfate (CaSO 4 ), due to the low comprehensive utilization rate of desulfurization ash due to its unstable properties, most iron and steel enterprises currently use concentrated accumulation to deal with desulfurization ash, occupying valuable land resources and causing serious environmental pollution

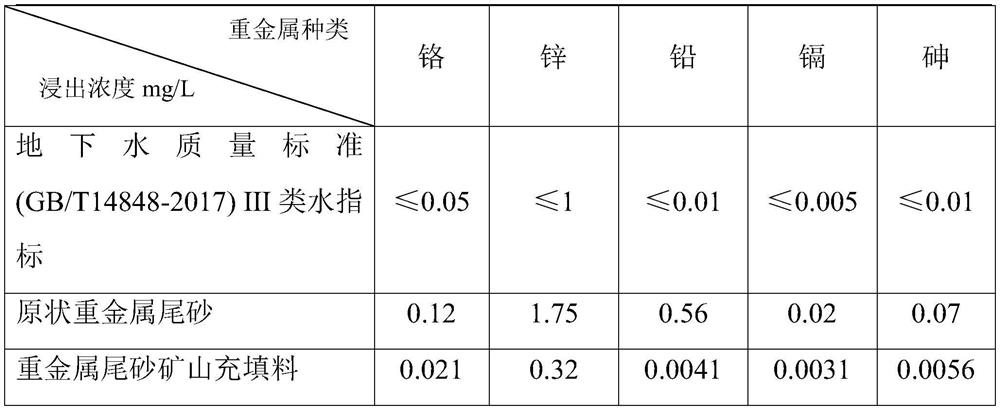

[0004] Tailings are raw ores that enter the concentrator and go through a series of processes such as crushing, grinding, and sorting. The remaining parts that cannot be used for production are discharged in the form of slurry. A large amount of tailings cannot be used as a resource and is accumulated in the tailings pond all year round. , the stockpiling takes up valuable land resources, and the heavy metals in the tailings permeate into the surrounding soil, causing serious ecological environmental pollution

[0005] At present, consolidating tailing sand as a mine filling material is the first choice to quickly and massively consume tailing sand. Cement is the first cement for mine filling, but the high price of cement increases the cost of mine filling materials, which limits the large-scale utilization of tailing sand in the field of mine filling. , and the heavy metal solidification / stabilization effect of cement is poor when cementing heavy metal tailings, resulting in low utilization of heavy metal tailings in the field of mine filling. Resource utilization is of great significance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

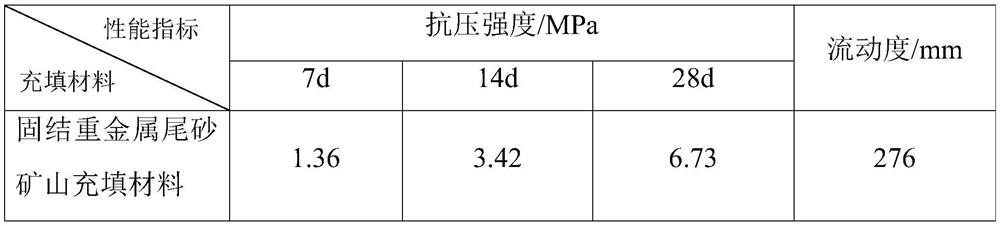

Embodiment 1

[0034]

[0036]

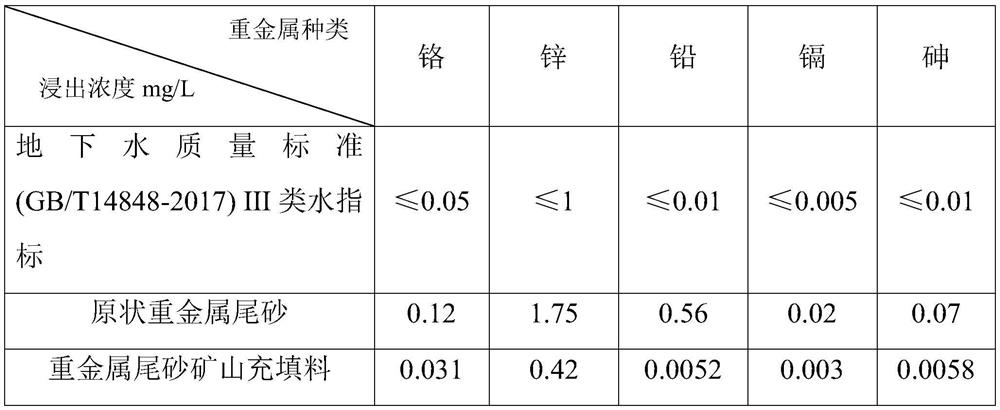

Embodiment 2

[0041]

[0043]

Embodiment 3

[0048]

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a method for preparing mine filling by cementing heavy metal tailings with solid waste in the iron and steel industry. S2, add dispersant, binder and heavy metal curing agent to the heavy metal tailings and stir evenly; S3, stir and mix the cementation agent of S1 and the heavy metal tailings of S2 in a certain proportion to make a uniform preparation into mine fillings. The invention utilizes solid waste from the iron and steel industry to cement heavy metal tailings, replaces cement-solidified tailings as mine filling materials, reduces mine filling costs, improves the comprehensive utilization of steel slag, desulfurization ash, tailings bulk solid waste and the mechanical strength of mine filling bodies.

Description

Method for preparing mine filling by cementing heavy metal tailings with solid waste in iron and steel industry technical field The present invention relates to the resource utilization of industrial solid waste in the iron and steel industry, in particular to the cementation of the solid waste in the iron and steel industry Method for preparing mine filling from heavy metal tailings. Background technique Steel slag is the industrial waste slag produced in the steelmaking process of the iron and steel industry, and the steel slag is poor in grindability due to low gelling activity, Factors such as poor accumulation stability limit the resource utilization of steel slag. In 2018, my country's steel slag output reached 120 million tons. The stock exceeds 1 billion tons, and the comprehensive utilization rate of steel slag is about 25%. Desulfurized ash is a kind of industrial solid waste that iron and steel industry adopts semi-dry flue gas desulfurization technology t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/00

CPCC04B28/006C04B2111/00724C04B2201/50C04B18/142C04B18/062C04B18/141C04B18/12C04B22/064C04B18/0427C04B22/062C04B22/16C04B24/383C04B24/18C04B24/10C04B24/16C04B22/124C04B22/12C04B22/148C04B22/147C04B24/122C04B22/085C04B22/00C04B14/28C04B24/04C04B16/0633C04B14/42C04B22/144C04B14/047C04B18/146C04B18/101C04B14/104C04B2103/0068Y02W30/91

Inventor 熊敬超姜明明郭华军宋自新邵雁刘子豪刘颖劳德平胡国锋向浩陈堃覃慧史记熙蒋庆肯杨振

Owner CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com