Oyster shell powder desalted sea sand AC-20 asphalt mixture and preparation method thereof

A technology of AC-20 and asphalt mixture, applied in the field of building materials, can solve problems such as environmental pollution and waste of resources, and achieve the effects of protecting the natural environment, making materials convenient, and reducing material prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of oyster shell powder desalinated sea sand AC-20 asphalt mixture, at first, produce desalinated sea sand according to the following process:

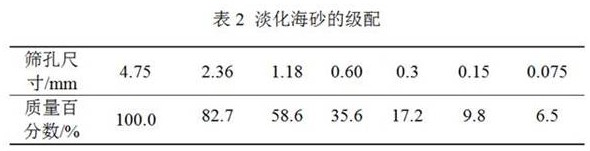

[0032] Collect the purchased sea sand; wash, dry, and pass through a 4.75mm sieve to obtain the desalinated sea sand in the required particle size range; the gross volume relative density of the desalinated sea sand is 2.685g / cm 3 The obtained sea sand is shown in Table 2 by the mass percent of the following sieve holes.

[0033]

[0034] Then, adopt the oyster shell powder listed in table 3, wherein the gross volume relative density of oyster shell powder is 2.708g / cm 3 . Described oyster shell powder is the discarded oyster shell (its CaO content ≥ 96.9%, Na 2 O content ≥ 0.56%), obtained by jaw crusher crushing, drying, planetary brand ball mill grinding, and passing through a 0.15mm sieve.

[0035]

[0036] The asphalt used is 50#A grade road asphalt, with a penetration of 53 (0.1mm), a softening ...

Embodiment 2

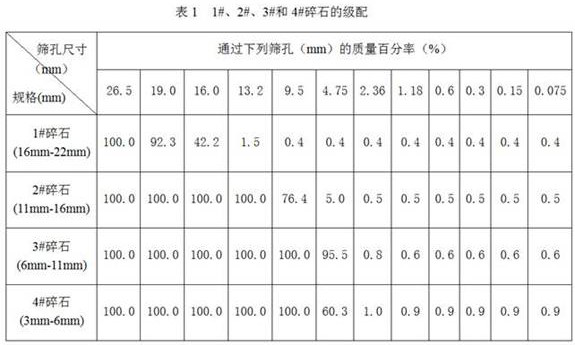

[0040] The performance of each raw material used in embodiment 2 is consistent with that described in embodiment 1, and the difference between embodiment 2 and embodiment 1 is: the present embodiment according to the mass percentage ratio: oyster shell powder: desalinated sea sand: 4# Crushed stone: 3# crushed stone: 2# crushed stone: 1# crushed stone is 3.8%: 26.6%: 6.4%: 15.2%: 18.6%: 25.1%. Mix these raw material components evenly and heat To 175°C, a mixed material was obtained.

[0041] In order to verify the road performance of the prepared oyster shell powder desalinated sea sand AC-20 asphalt mixture, the optimal asphalt ratio was determined by Marshall compaction test, and the prepared oyster shell powder desalinated sea sand AC-20 was added to the mixture prepared above. -20 asphalt mixture with 4.3% mass and 50#A grade road asphalt at a temperature of 165°C was mixed to prepare oyster shell powder desalinated sea sand AC-20 asphalt mixture, and the road performance ...

Embodiment 3

[0043] The performance of each raw material used in embodiment 3 is consistent with that described in embodiment 1, and the difference between embodiment 3 and embodiment 1 is: the present embodiment according to the mass percentage ratio: oyster shell powder: desalinated sea sand: 4# Crushed stone: 3# crushed stone: 2# crushed stone: 1# crushed stone is 3.0%: 23.8%: 6.4%: 15.2%: 19.5%: 28.4%. Mix these raw material components evenly and heat To 175°C, a mixed material was obtained.

[0044] In order to verify the road performance of the prepared oyster shell powder desalinated sea sand AC-20 asphalt mixture, the optimal asphalt content (3.7%) determined by the Marshall compaction test, the prepared oyster shell was added to the above prepared mixture Oyster shell powder desalinated sea sand AC-20 asphalt mixture was mixed with 50#A grade road asphalt with a mass of 3.7% and a temperature of 165°C to obtain an AC-20 asphalt mixture desalinated with oyster shell powder, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com