A blower-type rice processing conveyor located in the middle of the conveyor belt

A conveying device and rice processing technology, which is applied in the transportation of bulk materials, conveyors, transportation and packaging, etc., can solve the problems of incapable rice dust removal, time utilization that cannot be conveyed, and efficiency improvement that cannot be processed, etc., to save physical effort. The effect of consumption, reducing the amount of dust spread to the outside world, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

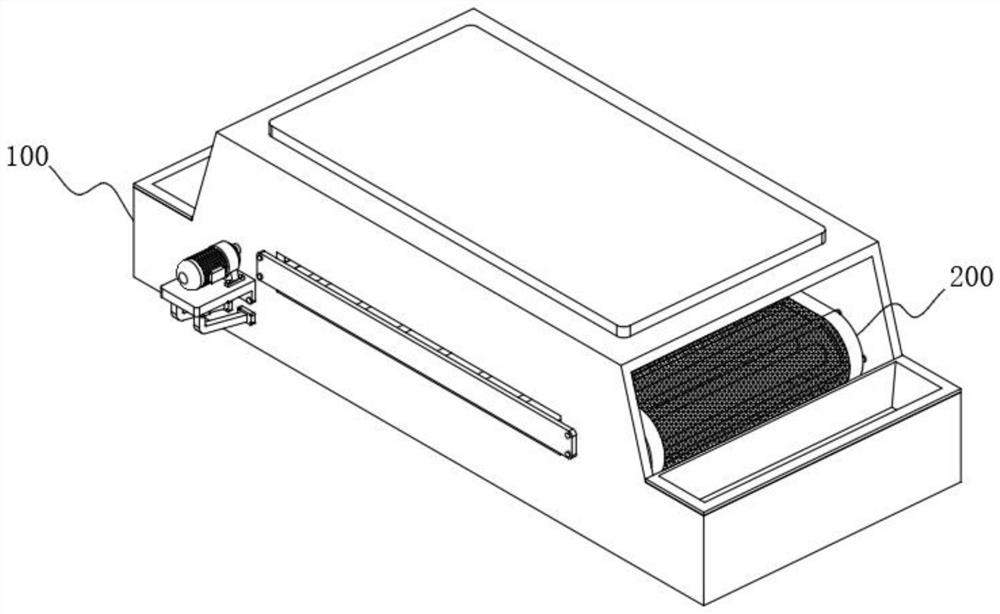

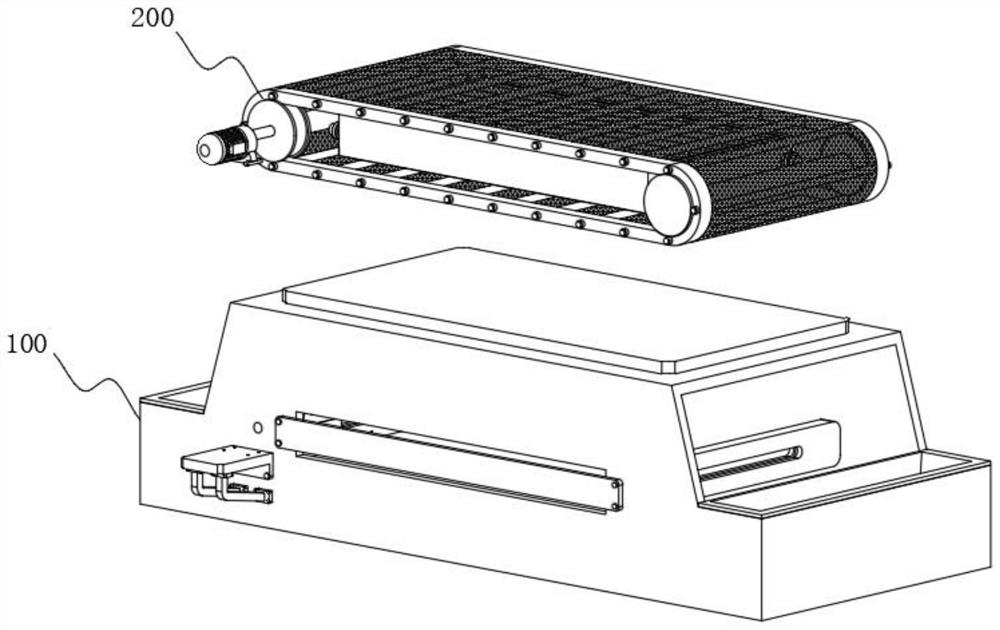

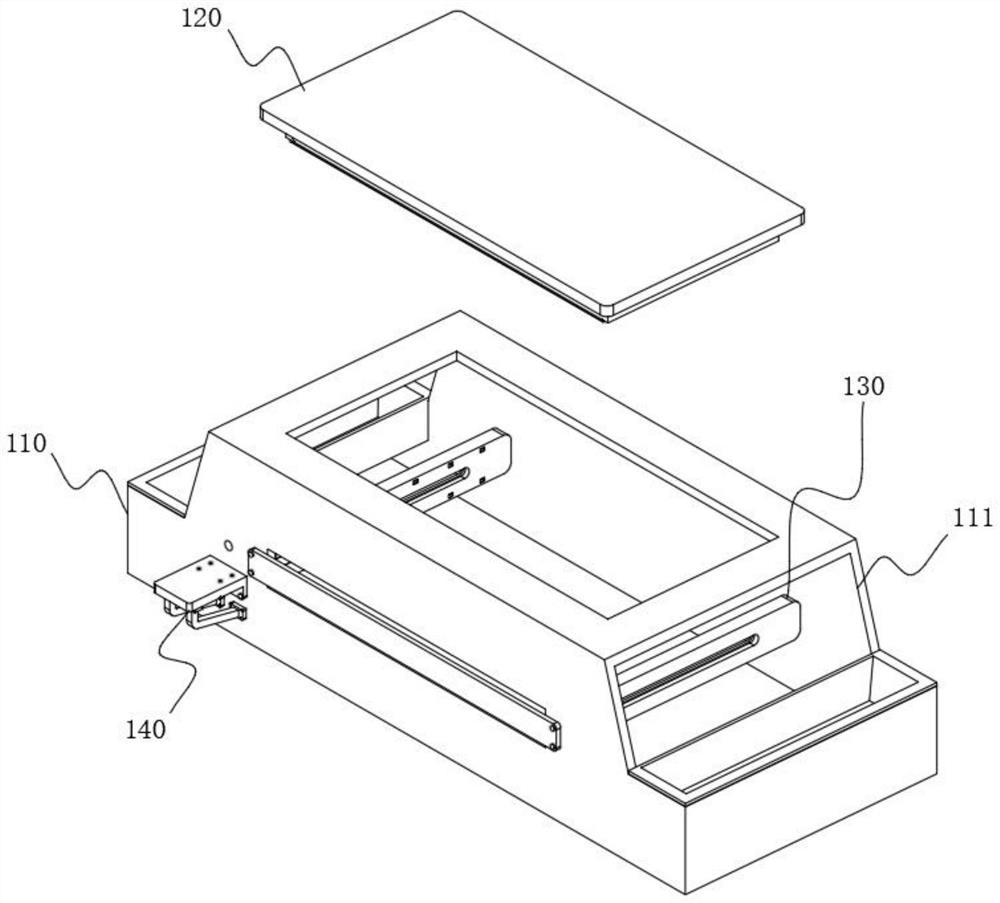

[0074] see Figure 1-Figure 14 As shown, the purpose of this embodiment is to provide a blower type rice processing conveyor located in the middle of the conveyor belt, including a support mechanism 100 and a blower type conveyor mechanism 200 arranged inside the support mechanism 100, and the support mechanism 100 includes a support platform 110, the inside of the support platform 110 is a hollow structure, and the front side and the rear side of the support platform 110 are provided with a transmission groove 111, and the material is discharged to the ventilation net 213 through the transmission groove 111 opened on the front side during use, and then through the rear side. Conveying chute 111 takes out material, and blast type conveying mechanism 200 comprises conveying device 210, and conveying device 210 comprises left conveyer belt 211 and right conveyer belt 212, and left conveyer belt 211 is arranged on the left side of right conveyer belt 212, between left conveyer bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com