Multi-stage elastic assembly applied to pedal simulation mechanism

A technology of pedal simulation and elastic components, which is applied to vehicle components, braking action activation devices, brakes, etc., can solve the problems of inconvenient disassembly, unreliable force transmission, and mixing, so as to achieve stable and reliable force transmission , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to illustrate the present invention in detail.

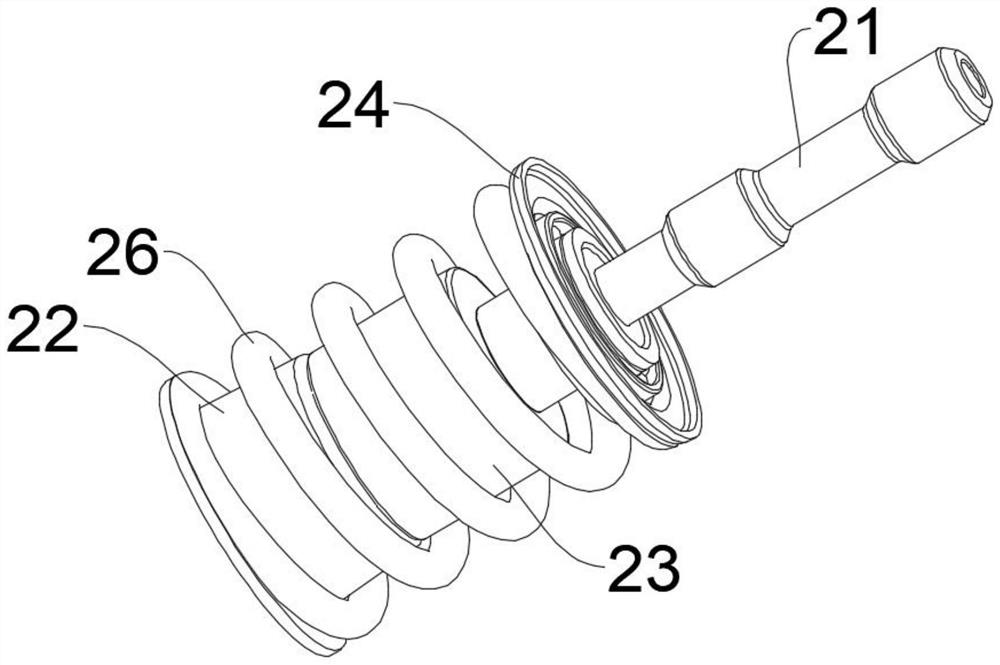

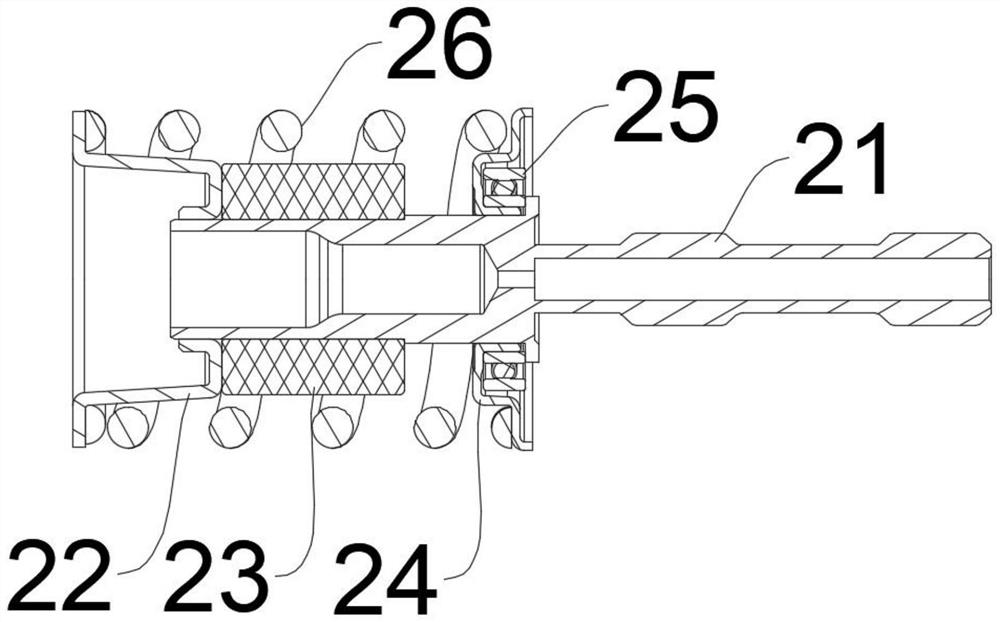

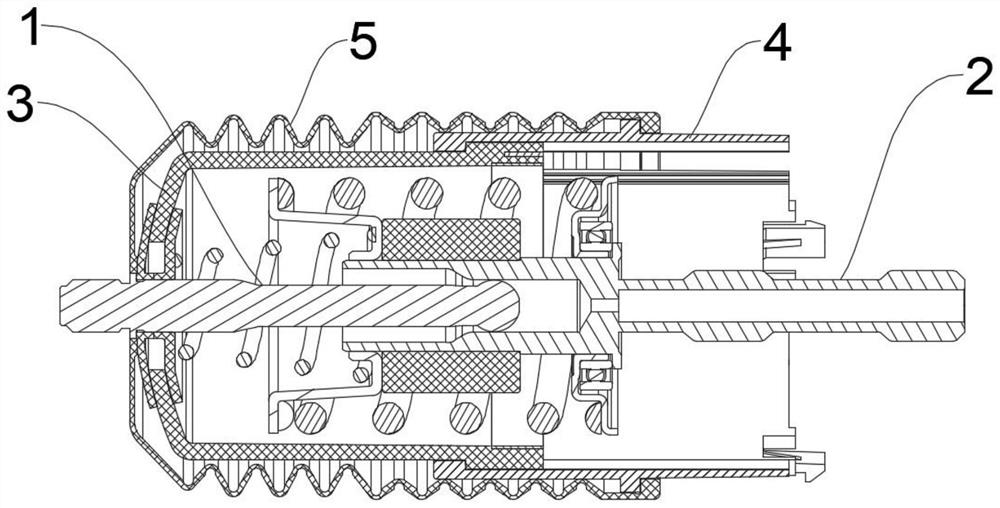

[0027] refer to figure 1 and figure 2 , is a schematic structural diagram of the multi-stage elastic assembly of the present invention; combining 3 to Figure 6 , is a schematic diagram of the application of the multi-stage elastic component of the present invention. and defined as figure 1 The direction from left to right shown on the paper is the direction from back to front in this embodiment. Among them, the multi-stage elastic assembly includes a guide rod 21, and the outer circumference of the guide rod 21 is sequentially set with a spring support seat 22, a third elastic member 23 and a bearing seat 24, and there is a gap between the spring support seat 22 and the bearing seat 24. A second elastic member 26 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com