Mechanical casting pouring system

A mechanical casting and electric technology, applied in foundry equipment, casting molding equipment, casting molds, etc., can solve the problems that the casting liquid is difficult to fill the mold, the effect of mold forming, and the lack of casting liquid, so as to achieve safe and convenient use and avoid voids. , to avoid the effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

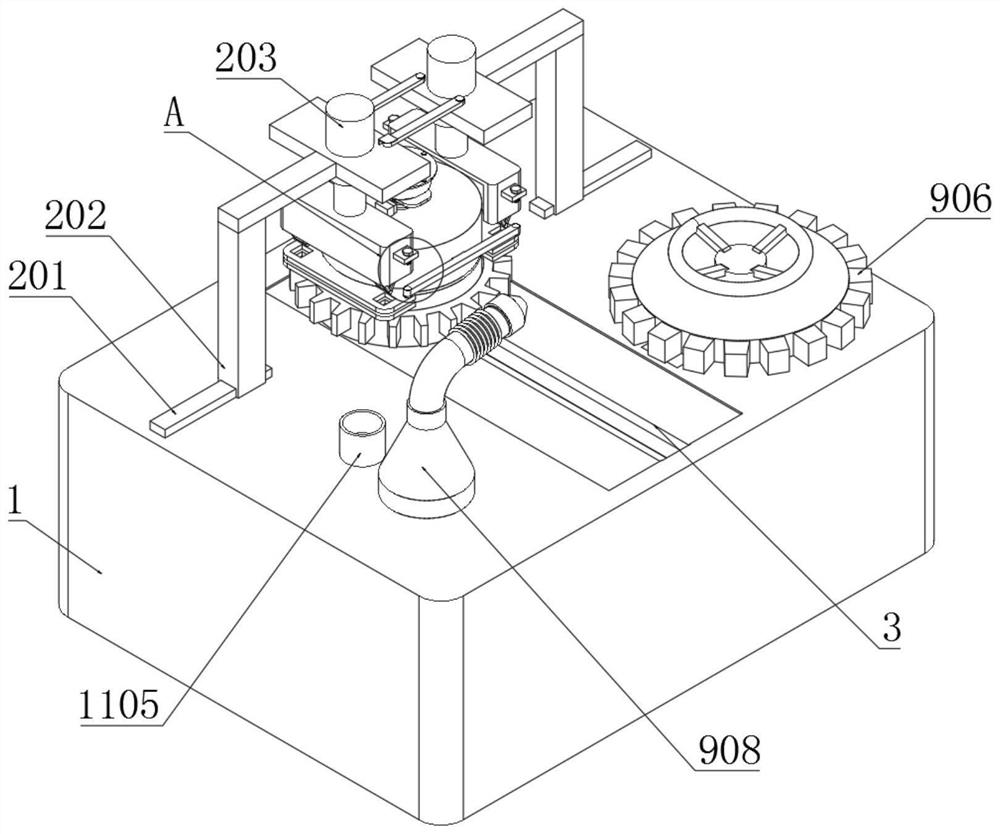

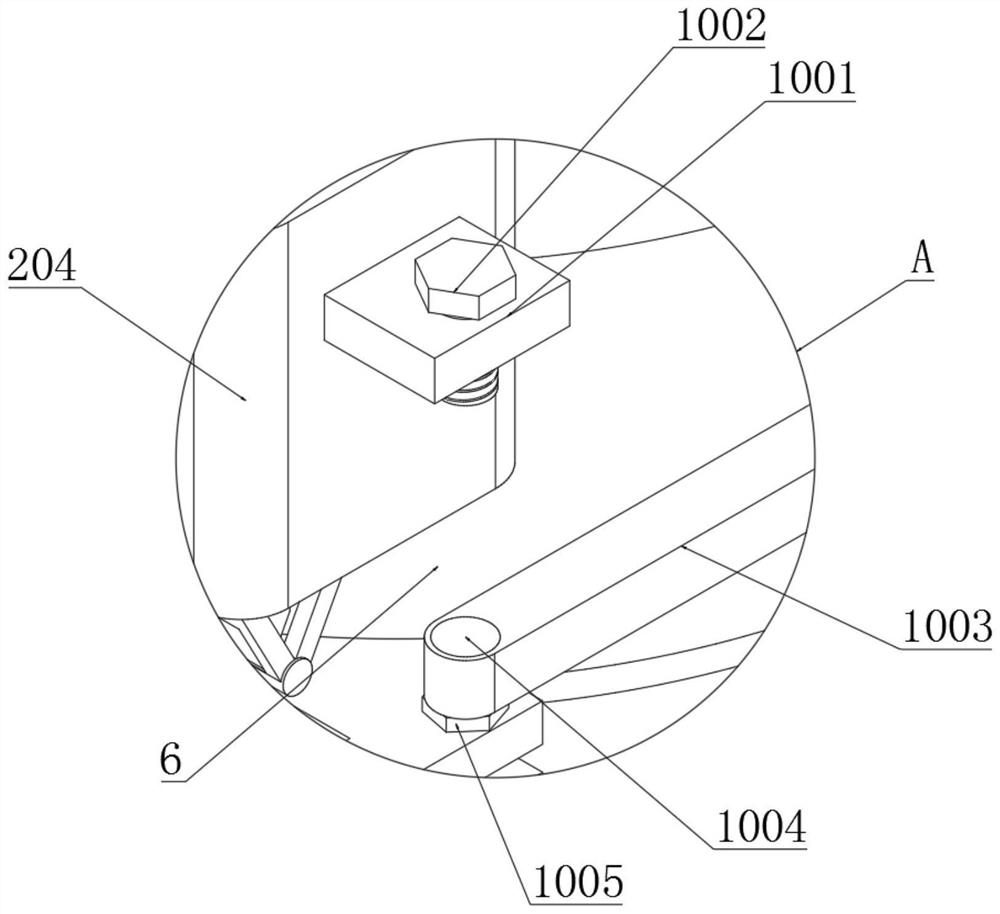

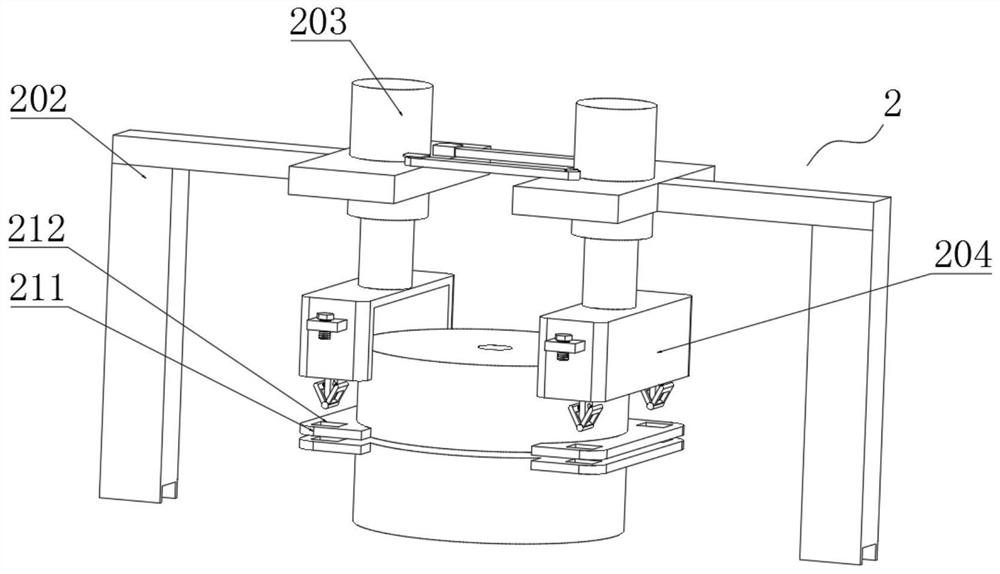

[0051] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a mechanical casting pouring system, including a workbench 1, a second electric slide rail 3 is installed in the middle of the top of the workbench 1, and a slider is slidably connected to the outer end of the second electric slide rail 3 12. The top of the slider 12 is rotatably connected with the placement cylinder 4, the lower mold 5 is placed inside the placement cylinder 4, the top of the lower mold 5 is clamped with the upper mold 6, and the middle part of the top of the upper mold 6 is provided with a pouring hole 7, and the inside of the pouring hole 7 is clamped. The pouring mechanism 8 is connected, and the input end of the second electric slide rail 3 is electrically connected with the output end of the external power supply;

[0052] The pouring mechanism 8 includes a delivery pipe 801, a guide cylinder 802, a clamping rod 803, a mounting rod 804, a threaded guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com