Organic light-emitting device, preparation method and display panel

A technology of organic light-emitting devices and fluorescent dopants, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as hindering development, efficiency roll-off, etc., to improve efficiency and reduce efficiency roll-off , Improve the effect of exciton utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0138] In the second aspect of the present specification, a method for preparing an organic light-emitting device is also provided. see Figure 5 , the preparation method comprises the steps of:

[0139] Step 501: Provide a substrate.

[0140] It should be noted that the substrate includes an anode and a hole transport layer.

[0141] It should be noted that the anode is disposed on the BP substrate. Optionally, the BP substrate is ultrasonically cleaned in acetone, ethanol and deionized water in sequence, and then dried in an oven for use.

[0142] Optionally, the anode is substantially prepared by sputtering an anode material onto the BP in a vacuum chamber.

[0143] Optionally, the hole transport layer is prepared by vacuum evaporation.

[0144] In some optional embodiments, the substrate further includes a hole injection layer, and the hole injection layer is located between the hole transport layer and the anode. Optionally, the hole injection layer is prepared by e...

Embodiment 1

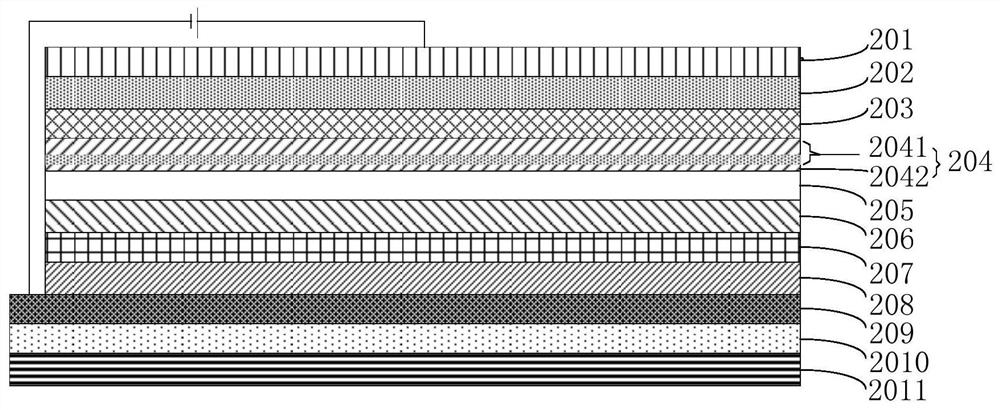

[0175] Example 1: Top emission doped organic light emitting device

[0176] The specific structure is as follows: ITO / HIL (10nm) / HTL (90nm) / p-type matrix material (15nm)+p-type matrix material (20nm): FD (10%)+p-type matrix material (5nm) / Interlayer (x nm ) / n-type host material (40nm) / ETL (50nm) / EIL (3nm) / Mg:Ag. Here, x represents the thickness of Interlayer. Wherein, x=1 nm, 4 nm or 8 nm.

Embodiment 2

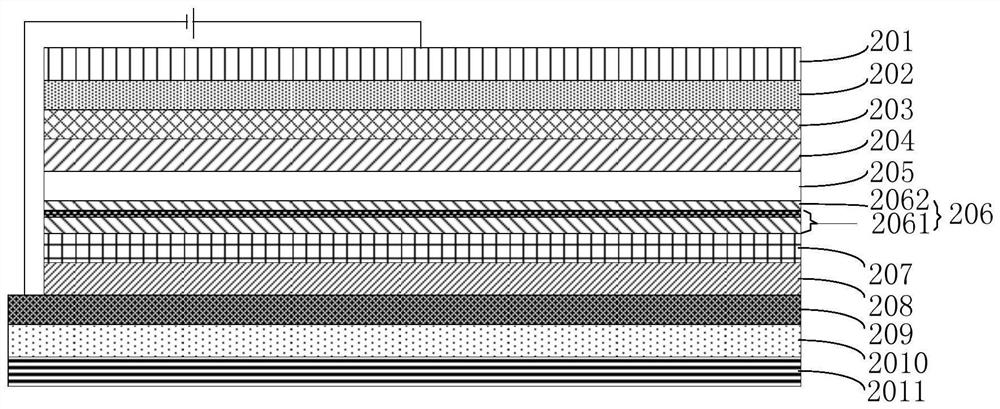

[0177] Example 2: Top emission doped organic light emitting device

[0178] The specific structure is as follows: ITO / HIL (10nm) / HTL (90nm) / p-type matrix material (40nm) / Interlayer (xnm) / n-type matrix material (5nm)+n-type matrix material (20nm):FD (10%) +n-type host material (15nm) / ETL (50nm) / EIL (3nm) / Mg:Ag. Here, x represents the thickness of Interlayer. Wherein, x=1nm, 4nm, 8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com