Quantitative generation-reaction device and synchronous detection method for ammonia gas

A reaction device and ammonia gas generation technology, applied in the field of experimental instruments, can solve the problems of pollution detection, experimental result error, leakage, etc., and achieve the effect of avoiding pollution and leakage, and accurately calibrating real-time detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

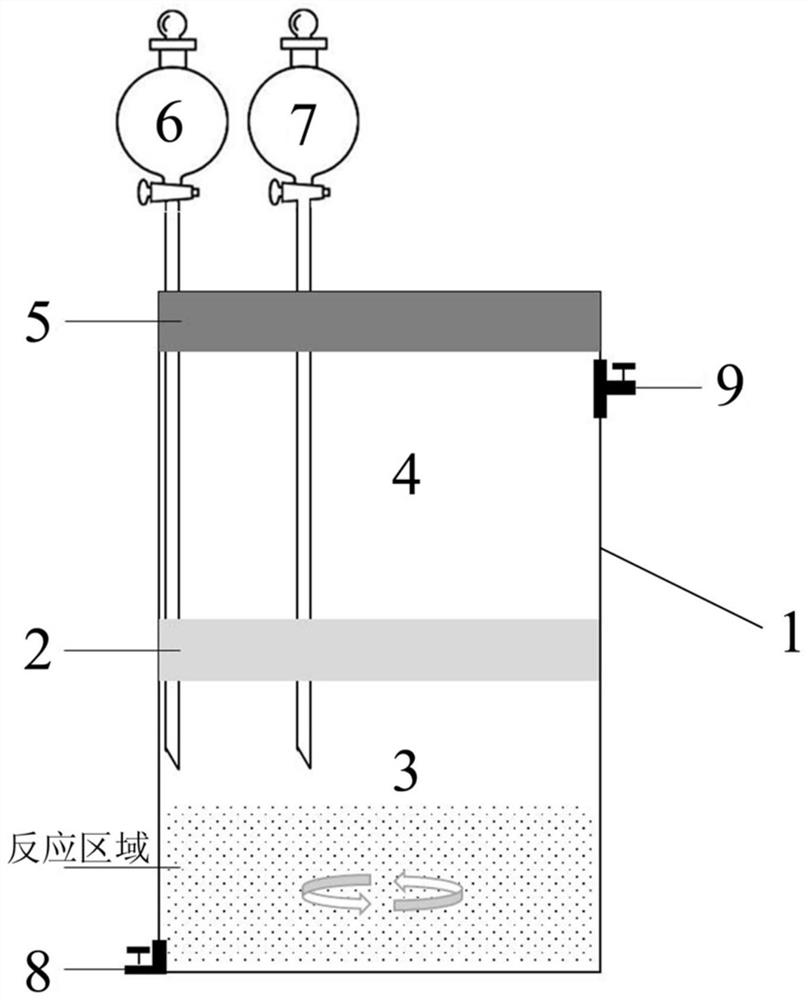

[0025] A quantitative ammonia gas generation-reaction device, such as figure 1 As shown, a first tank body 1 is included, and a desiccant spacer layer 2 (soda lime) is horizontally arranged in the first tank body 1, and an ammonia gas generating chamber 3 is below the desiccant spacer layer 2, so Above the desiccant spacer layer 2 is an ammonia gas reaction chamber 4; the top of the first tank body 1 is provided with a rubber cover 5 for keeping the container airtight, and the rubber cover 5 is provided with NH 4 Cl dosing funnel 6 and NaOH dosing funnel 7, the NH 4 The ends of the Cl dosing funnel 6 and the NaOH dosing funnel 7 are all arranged below the desiccant spacer layer 2; the bottom end of the side wall of the first tank body 1 is provided with a first valve 8 for the reaction liquid Sampling and discharge of reaction liquid, the top of the side wall of the first tank body 1 is provided with a second valve 9, which is used for the discharge of air in the first tank b...

Embodiment 2

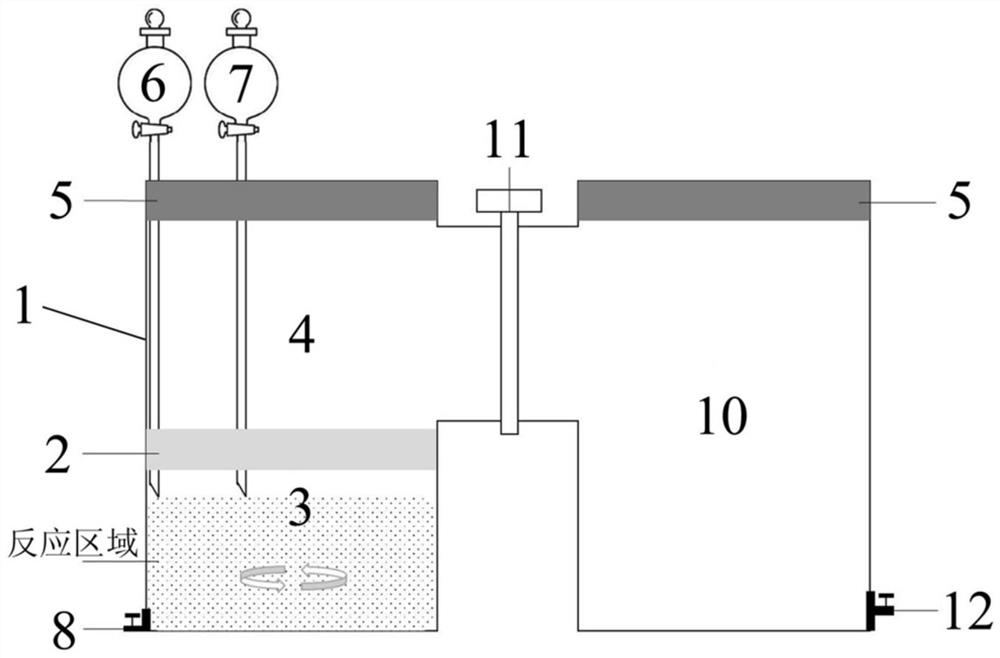

[0027] A quantitative ammonia gas generation-reaction device, such as figure 2 As shown, the split structure designed on the basis of Embodiment 1 (one-piece structure) also includes a second tank body 10, a third valve 11 and a fourth valve 12, wherein the second tank body 10 and the The first tank body 1 communicates with each other, and the communication is located at the side wall of the ammonia reaction chamber 4, and the communication is provided with a third valve 11, which is used to separate the ammonia generating device from the reaction device to form an independent A reaction place with quantitative ammonia concentration, the bottom end of the side wall of the second tank body 10 is provided with a fourth valve 12, which is used for the discharge of air in the second tank body 10 and the gas sampling of the generated ammonia gas, so The top of the second tank body 10 is also provided with a rubber cover 5 .

Embodiment 3

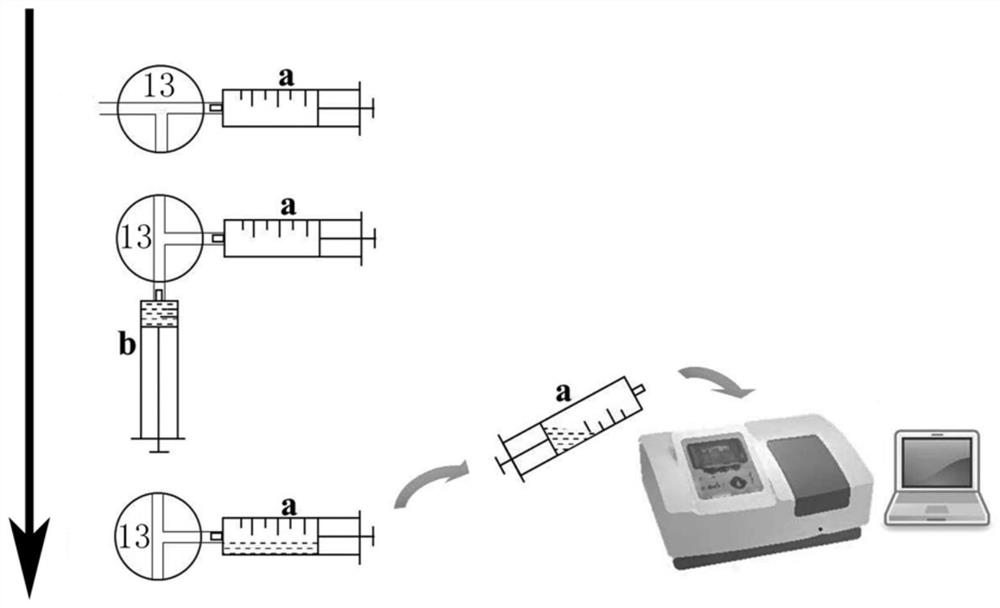

[0029] The ammonia gas synchronous detection method based on the ammonia gas quantitative generation-reaction device of embodiment 2, concrete steps are as follows:

[0030] (1) Quantitative generation of ammonia gas: firstly, the ammonium chloride solution is mixed with NH 4 Add the Cl dosing funnel 6 into the ammonia gas generating chamber 3 below the desiccant spacer layer 2, then slowly add sodium hydroxide from the NaOH dosing funnel 7 into the ammonium chloride solution in the ammonia gas generating chamber 3, and start Stir at a constant speed, and the following reaction occurs:

[0031] NH 4 Cl+NaOH=NaCl+NH 3 ↑+H 2 O,

[0032] Until the pH of the solution is more than or equal to 12, it is considered that all ammonium ions in the solution are all converted into ammonia, and the addition of sodium hydroxide is stopped, and the reaction is completed; use wet phenolphthalein test paper to carry out ammonia gas at the second valve 9 or the fourth valve 12. The generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com