Diamond fretsaw cutting tension control device

A diamond wire saw and tension control technology, which is used in grinding automatic control devices, fine working devices, manufacturing tools, etc., to achieve the effect of improving stability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in detail and completely below with reference to the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

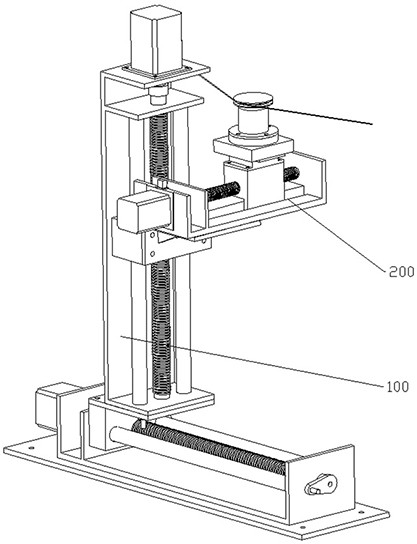

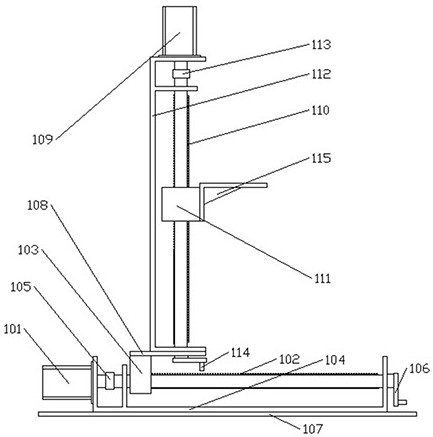

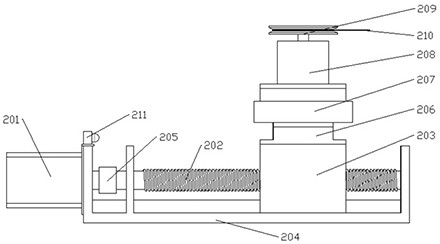

[0017] A diamond wire saw cutting tension control device includes a moving module 100 and a tension control module 200 , and the tension control module 200 is installed on the moving module 100 . The mobile module 100 includes a horizontal displacement mechanism and a vertical displacement mechanism. Horizontal displacement mechanism comprises stepper motor one 101, leading screw one 102, leading screw slider one 103 and guide rail one 104 that cooperate with stepper motor one 101 to move, and leading screw one 102 is connected with stepper motor through coupling one 105 The output shaft of one 101 is connected, and the leading screw one 105 is fixedly connected with the manual crank one 106 by screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com