Rack oiling device

A technology for applying oil to a rack and an oil pump, applied in the field of machinery, can solve problems such as being easy to be blocked, and achieve the effect of avoiding easy blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

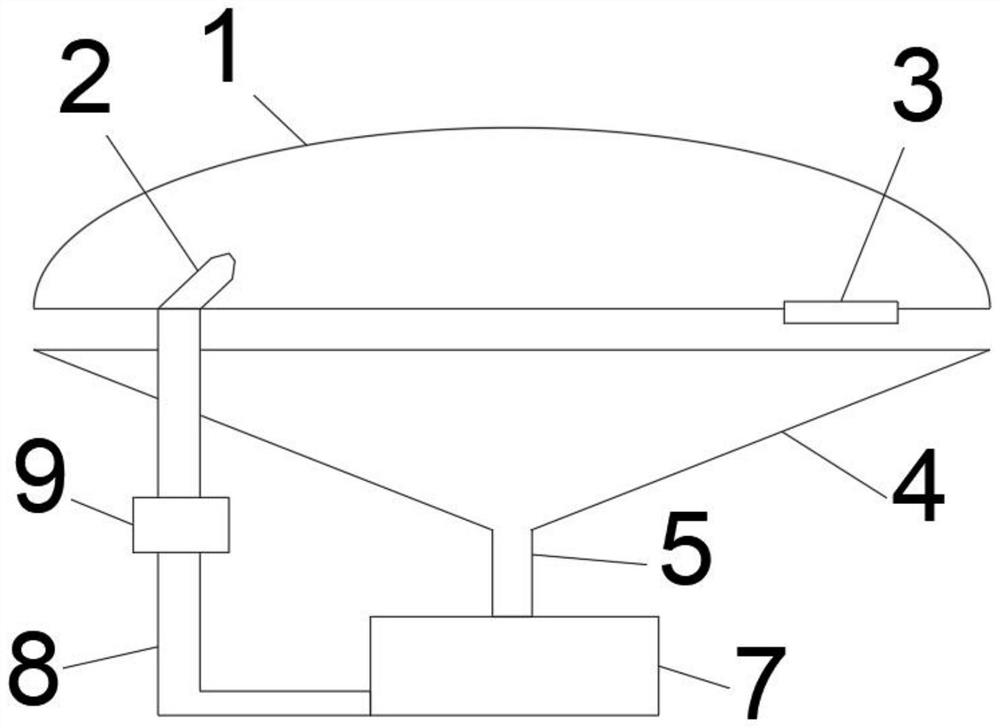

[0014] Such as figure 1 A rack oiling device shown includes an elliptical cover plate 1, a high-pressure spray nozzle 2 is installed at one focus of the elliptical cover plate 1, and the other focus forms a passage through which the rack 3 passes; the elliptical cover plate A recovery hopper 4 is installed below 1, the bottom of the recovery hopper 4 is a discharge port 5, and the bottom of the discharge port 5 is an oil storage tank 7, which communicates with the high-pressure nozzle 2 through a communication pipe 8; an oil pump 9 is installed on the communication pipe 8.

[0015] The oil pump 9 is a high-pressure oil pump. The connecting pipe 8 communicates with the bottom of the fuel tank 7 .

[0016] The oval cover plate 1 is a stainless steel plate. Recovery hopper 4 is conical.

[0017] The invention utilizes the principle that the light emitted from one focal point of the ellipse must pass through the other focal point after reflection, and the oil sprayed by the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com