Small orchard operation platform

A technology for operating platforms and orchards, applied in the field of orchard management and operating machinery, can solve problems such as low labor efficiency, time-consuming, and high risk coefficients, and achieve the effects of improving production efficiency, convenient operation, and improving the level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

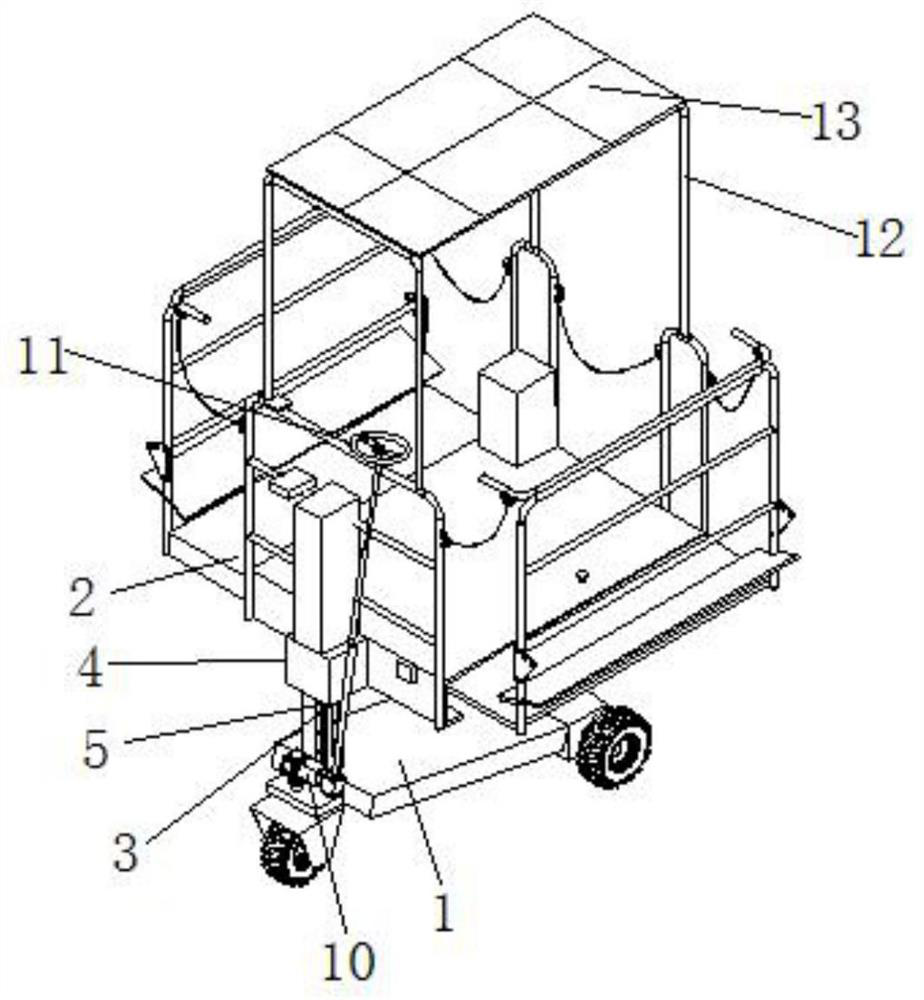

[0032] Such as figure 1 As shown, a small orchard work platform is disclosed in this embodiment, comprising a walking chassis 1, a working platform 2 is arranged above the walking chassis 1, and a vertical guide post 3 is welded on the front of the walking chassis 1, and the guide post 3 The upper cover is provided with a guide sleeve 4, the guide sleeve 4 is connected with the working platform 2 at the rear, and the guide sleeve 4 moves up and down along the guide column 3 through the rack and pinion driving structure 5.

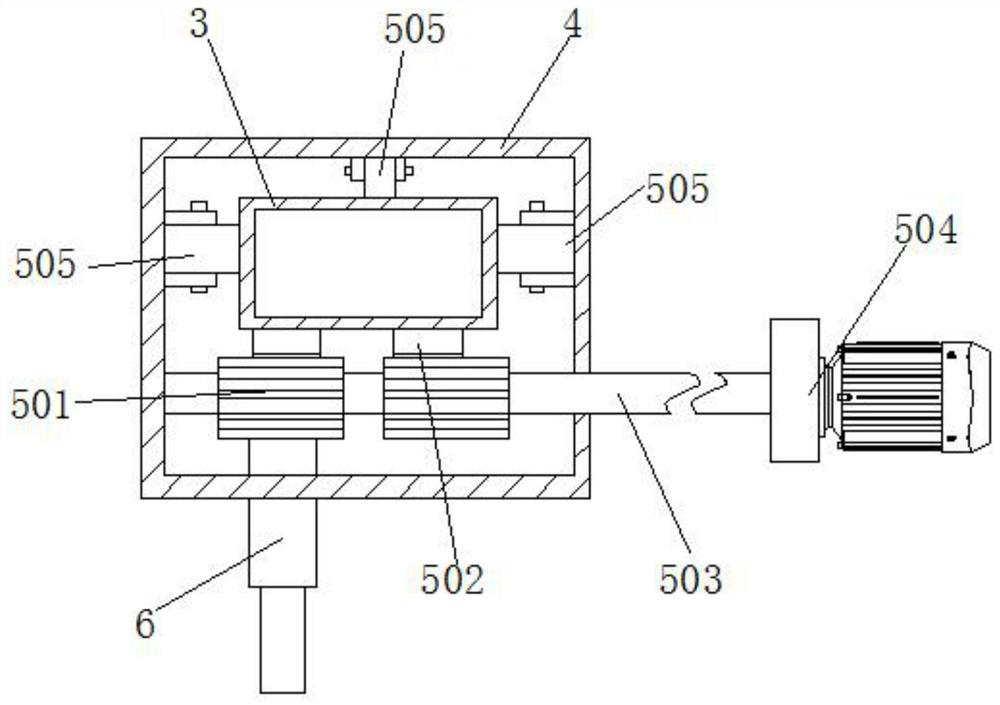

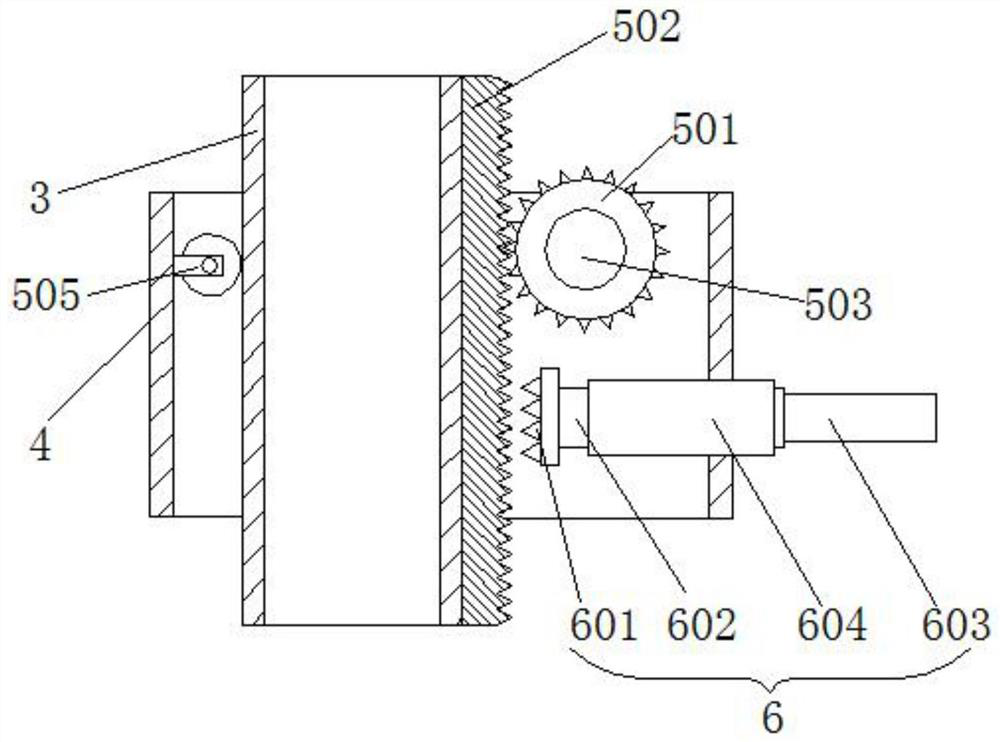

[0033] Such as figure 2 As shown, the rack and pinion driving structure 5 includes a gear 501 and a rack 502 that mesh and cooperate. Rotationally connected on the guide sleeve 4, and the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com