Method for operating a regenerative heat reservoir arrangement and heat reservoir arrangement

A regenerator and regenerative technology, applied in regenerative heat exchangers, thermal storage equipment, indirect heat exchangers, etc., can solve the problems of low utilization rate and increase energy storage costs, and achieve the reduction of thermal storage costs, The effect of low compressor power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

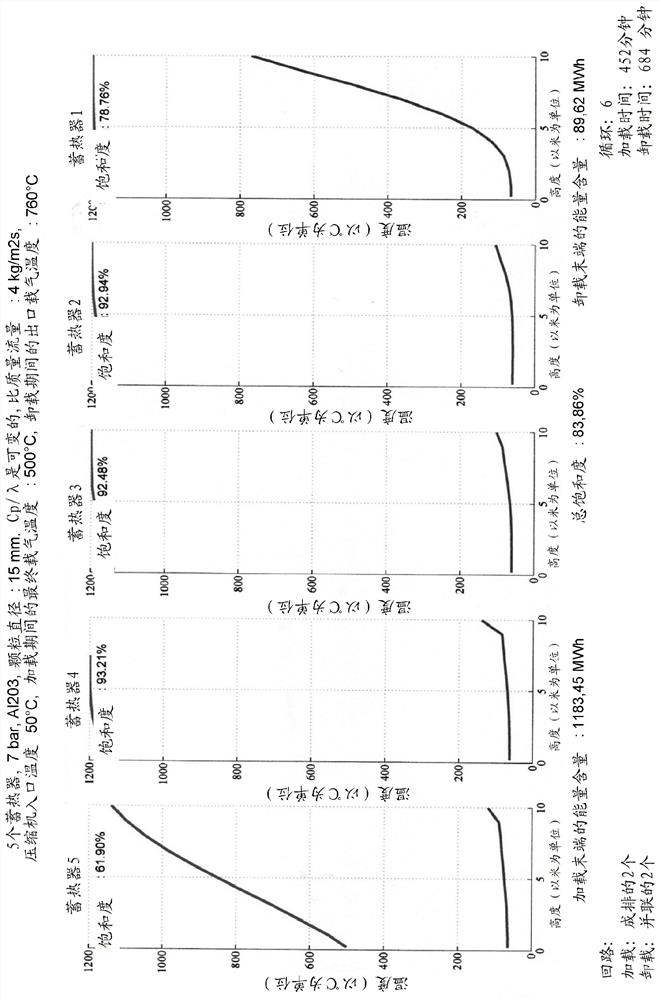

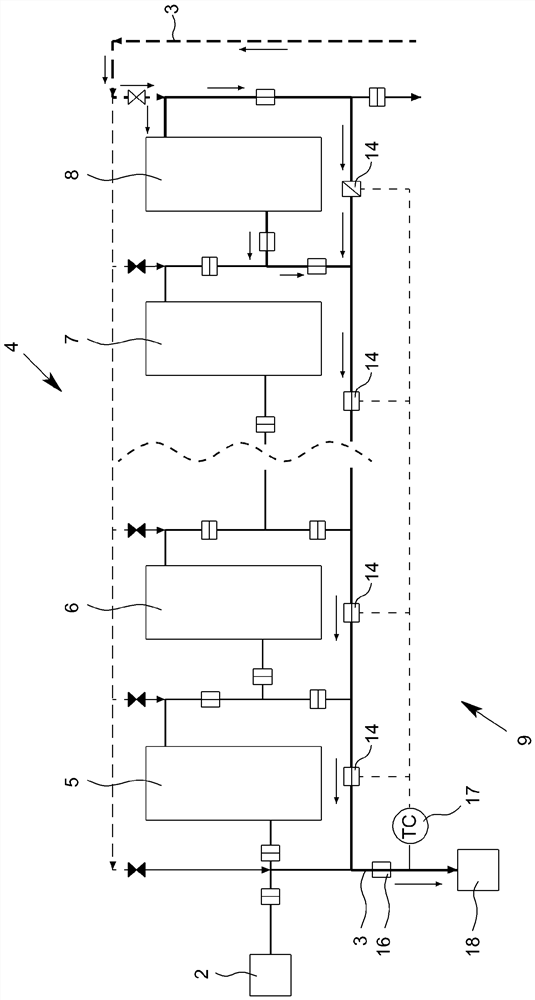

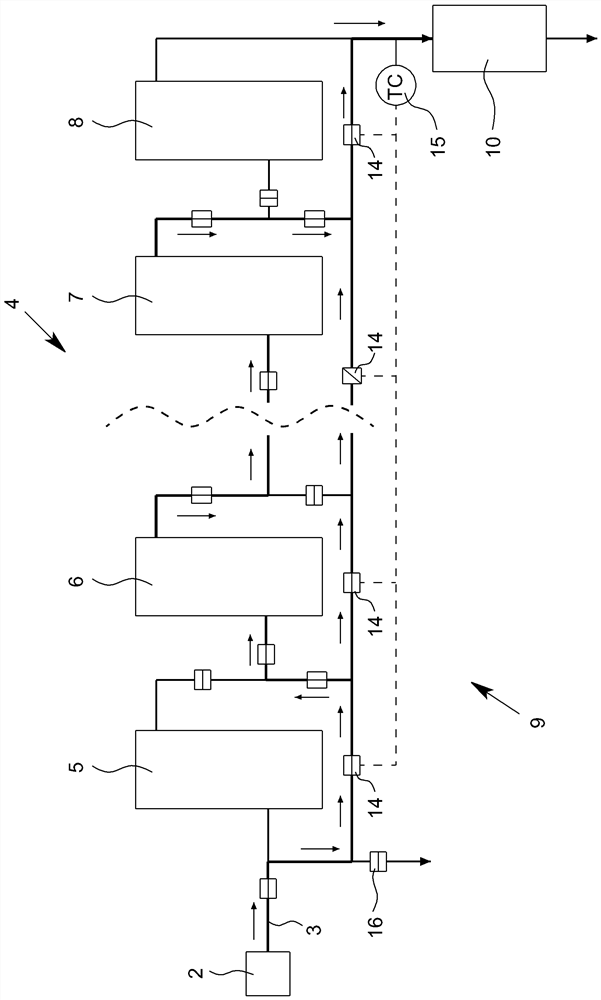

[0046] figure 1 Shown is a known heat accumulator arrangement 1 with at least one gas heater 2 for heating a carrier gas 3 , in particular air, and with a heat accumulator row 4 , for example with a series Four other heat accumulator modules 5 to 8 are connected. Of course, more or fewer than four heat accumulator modules 5 to 8 can also form a heat accumulator row 4 .

[0047] A blower or compressor 6 is also provided.

[0048] The heat accumulator arrangement 1 may correspond to the heat accumulator arrangement described in the publication DE 10 2014 017 346 A1 and is operated according to the procedure described in the aforementioned publication. The disclosure content of DE 10 2014 017 346 A1 is fully included in the disclosure content of the present description both with respect to the type and design of the heat storage device 1 and with regard to known operating procedures.

[0049] During the loading cycle or during the loading process of the regenerator modules 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com