Gas stove waste heat recovery method and device

A technology of waste heat recovery and gas stoves, which is applied in heating methods, household heating, household stoves/stoves, etc., can solve the problems of unsatisfactory heat exchange effects and high requirements for heat exchangers, and achieve the single uncontrollable and controllable waste heat recovery Convenient and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

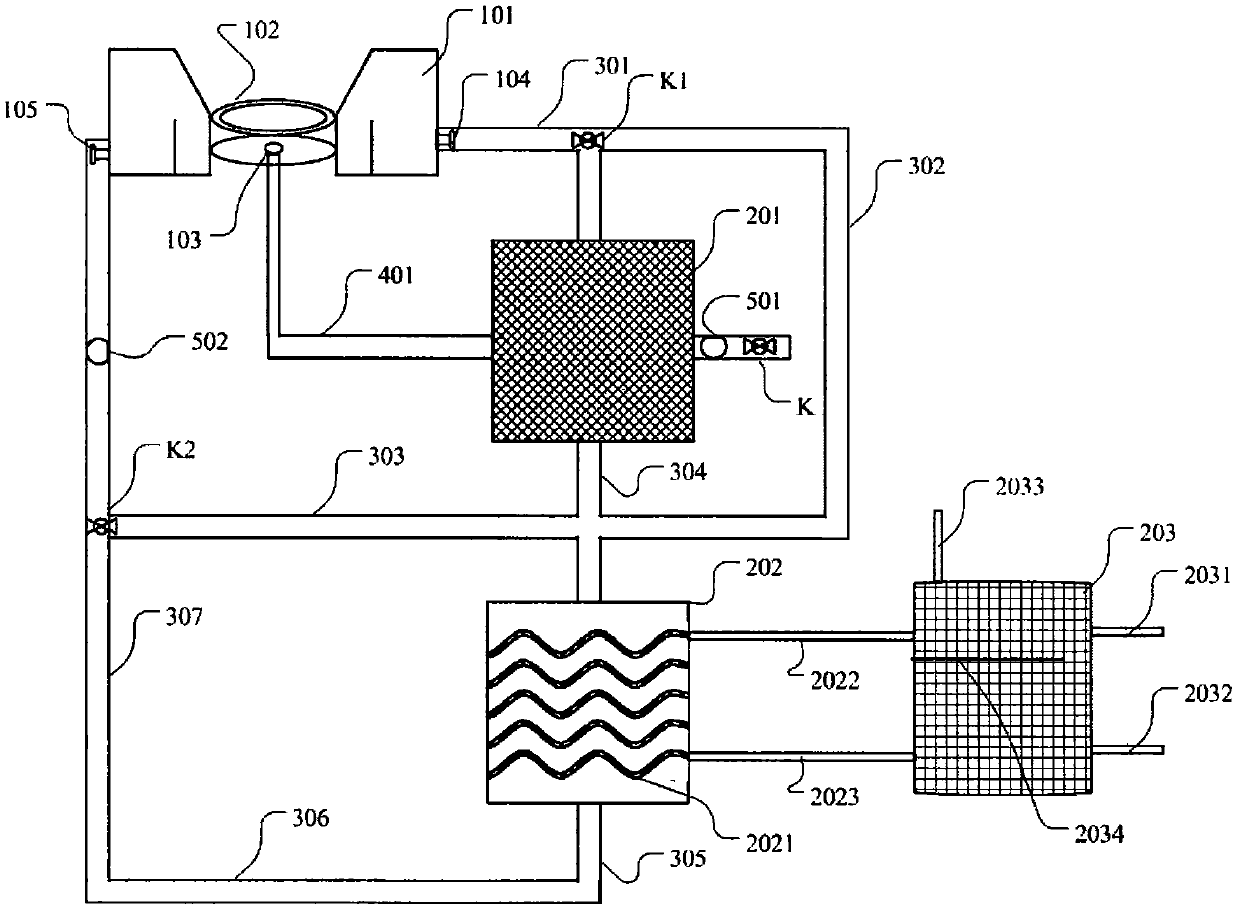

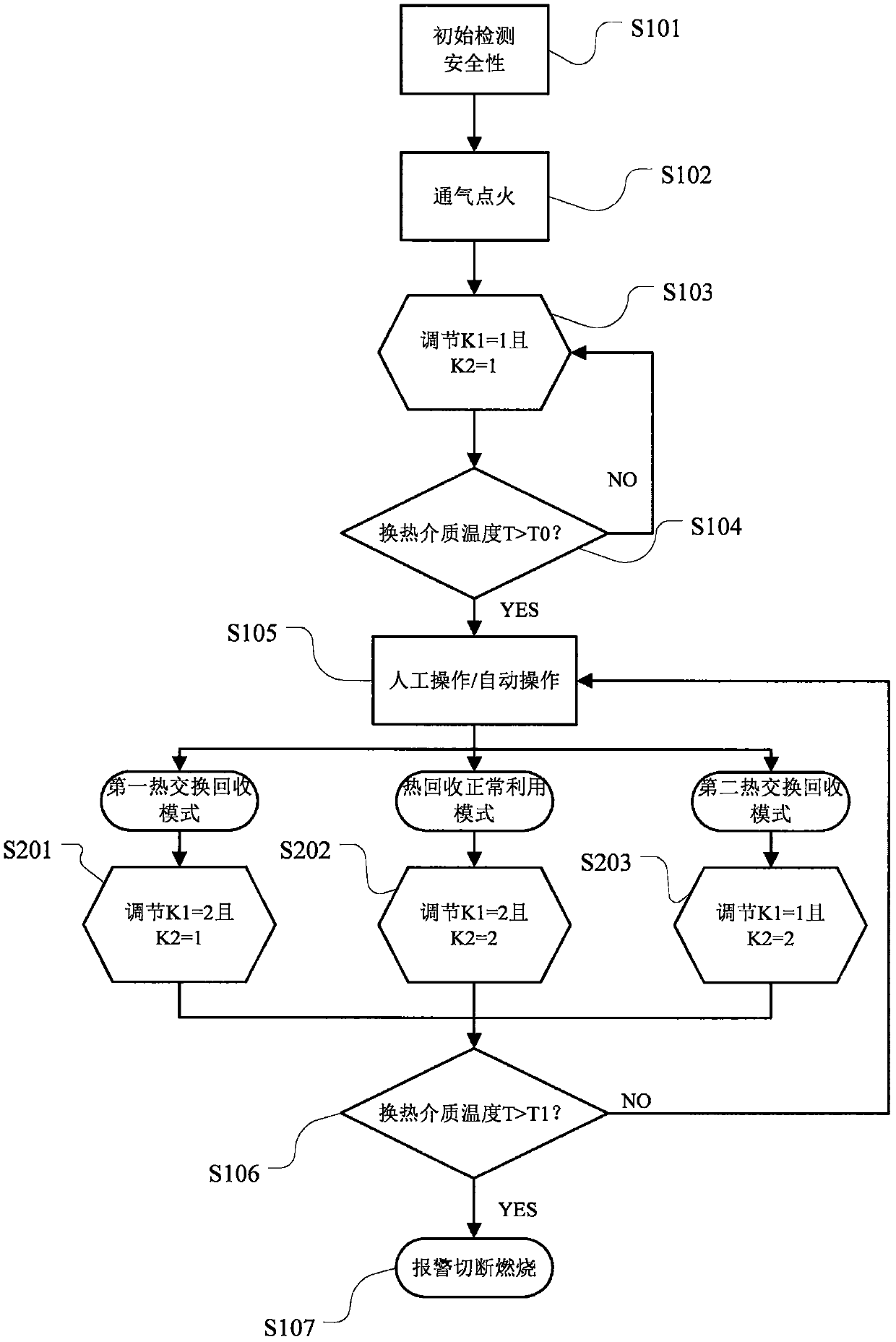

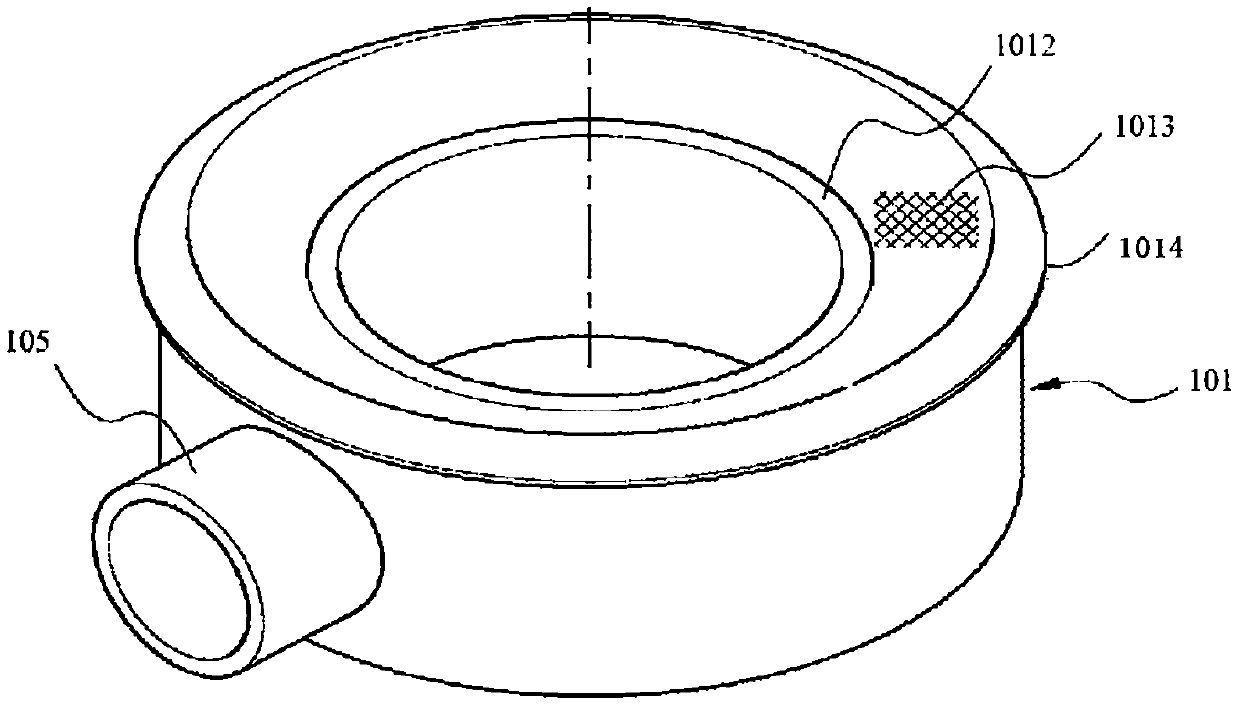

[0042] Such as figure 1 As shown, the gas stove waste heat recovery device of the present invention includes a burner assembly, a heat exchanger assembly, a water storage tank and a connecting control pipeline assembly, wherein the burner assembly includes a burner 101 and a support ring 102 that can be integrated into the gas stove, An air outlet 103 is provided at the bottom of the burner 101 to form a combustion zone for igniting the gas-air mixture, and an annular cavity for accommodating the heat exchange medium fluid is formed inside the burner 101 along the annular body, and in the burner 101 shell The two sides are respectively provided with a waste heat fluid outlet 104 and a waste heat fluid inlet 105 connected to the annular cavity.

[0043] The heat exchanger assembly includes a first heat exchanger 201 and a second heat exchanger 202, wherein the upstream fluid pipeline 301 of the first heat exchanger 201 communicates with the waste heat fluid outlet 104, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com