Ultra-high voltage transmission line security inspection equipment

A transmission line and UHV technology, applied in the field of UHV transmission line security inspection equipment, can solve problems such as power supply accidents, inconvenient maintenance work, pedestrian injuries, etc., and achieve the effects of enhancing earthquake resistance, avoiding damage, and reinforcing slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

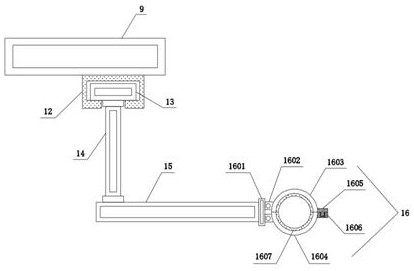

[0035] see Figure 1-6 , a UHV transmission line security inspection equipment, comprising a base 1, a moving mechanism 2 is fixedly installed on the bottom of the base 1, a stabilizing mechanism 3 is fixedly installed on the left and right sides of the base 1, and the left and right sides of the top of the base 1 Both sides are fixedly connected with supporting columns 4, and the tops of the supporting columns 4 are provided with installation grooves 5, and hydraulic cylinders 6 are fixedly installed inside the installation grooves 5, and the output ends of the hydraulic cylinders 6 are fixedly connected There is a working bottom plate 7, four corners of the top of the working bottom plate 7 are fixedly connected with upright columns 8, and the tops of the upright columns 8 are fixedly connected with a working top plate 9, and the top of the working top plate 9 is fixedly installed with a solar power generation mechanism 10. Guardrails 11 are fixedly connected between the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com