Moment rotary rigidity high-low temperature testing device

A test device, high and low temperature technology, applied in the direction of measuring device, elastic test, machine/structural component test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

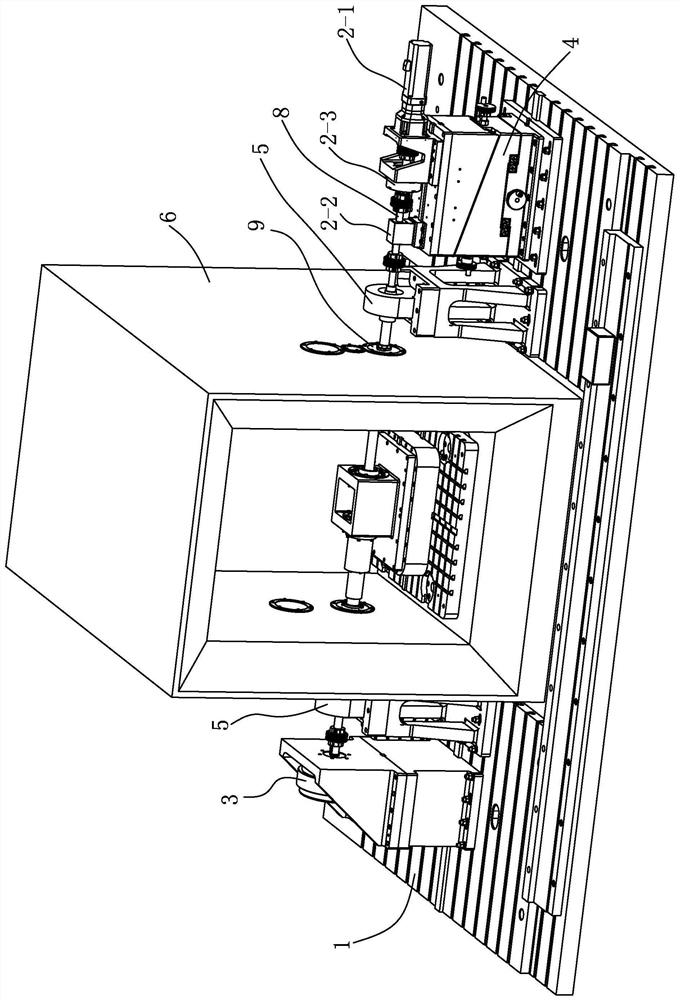

[0023] see Figure 1-Figure 5 As shown, a high and low temperature test device for torque rotation stiffness in this embodiment includes a basic platform 1, an integrated torsion measurement module 2, an overload protection module 3, an adjustment module 4 and a support module 5, and the overload protection module 3 is a magnetic powder brake Overload protection module;

[0024] The overload protection module 3, the support module 5, the high and low temperature box 6 and the adjustment module 4 are installed on the basic platform 1, the high and low temperature box 6 is located between the two support modules 5, and the torsional measurement integrated module 2 is installed on the adjustment module 4, The torsion measurement integrated module 2 includes a torsion drive module 2-1, a dynamic torque sensor 2-2 and an angle encoder 2-3, and the torsion drive module 2-1, the overload protection module 3 and the support module 5 are coaxially arranged , the transmission shaft 8 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com