Stereoscopic vision three-dimensional displacement measurement method based on structure surface point features

A technology of stereo vision and structured surface, applied in measurement devices, image data processing, instruments, etc., can solve problems such as poor practicability and limitations of artificial targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0078] according to Figure 1 to Figure 9 As shown, the present invention provides a stereoscopic three-dimensional displacement measurement method based on structure surface point features, specifically:

[0079] A stereo vision three-dimensional displacement measurement method based on structure surface point features, comprising the following steps:

[0080] Step 1: Use a stereo vision system to collect images of the structural surface in the deformation process to obtain a left and right image sequence, and preprocess the image sequence to obtain a reference image; the stereo vision system, such as figure 1 shown.

[0081] The step 1 is specifically:

[0082] Step 1.1: Preprocessing the image sequence, selecting the region of interest on the left image at the initial moment, taking the object of interest on the structural surface as the measurement target, and selecting a rectangular region containing the measurement target on the left image at the initial moment as the ...

specific Embodiment 2

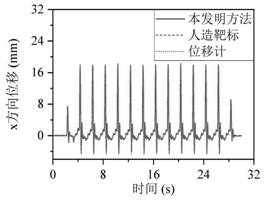

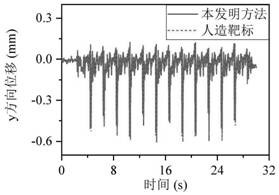

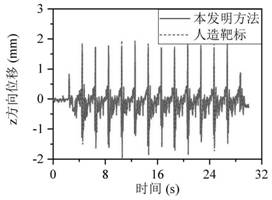

[0139] This embodiment is a three-dimensional displacement measurement test of a three-story frame model seismic shaking table, which is specifically prepared according to the following steps:

[0140] The three-layer frame model used in this embodiment is as follows Figure 6 As shown, the length and width of the model structure are 410mm×150mm, and the height is 900mm. The vibrating table used in the test is a WS-Z30-50 small vibrating table produced by Beijing Pope Company. The size of the vibrating table is 480mm×520mm, and the height of the table is 300mm. The vibrating table is a one-way vibrating table, and the vibration direction is selected as the x direction . During the three-dimensional displacement measurement test, high-strength double-sided adhesive is used to paste the test image and the circular target at the measuring point on the surface of the model. The size of the test image is 100mm×100mm. The diameter of the circle is 35mm, black on the outside and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com