Automatic pressurizing and water mixing valve of water heater

A technology of automatic pressurization and water mixing valve, which is applied in branch pipelines, pipes, pipes/pipe joints/pipes and other directions, which can solve the problems of low water pressure and cumbersome manual temperature adjustment process, and achieve the effect of good user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

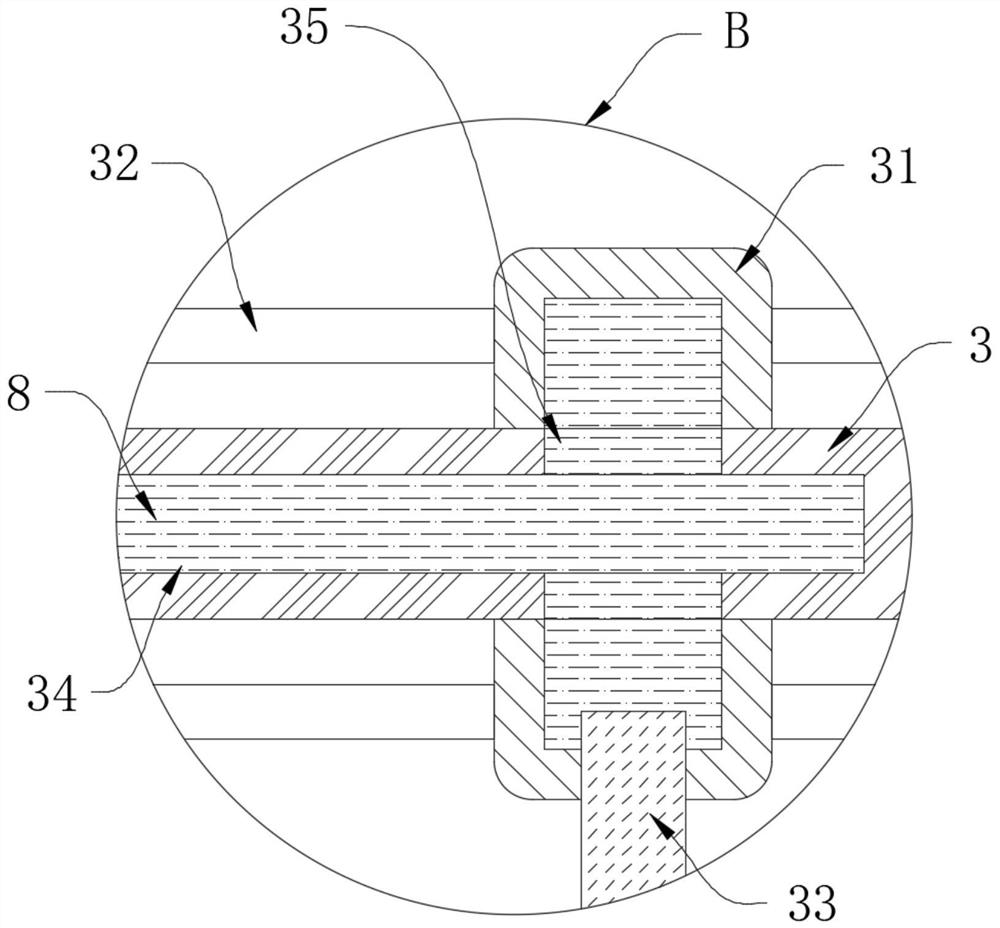

[0022] refer to Figure 1-4 , an automatic pressurized water mixing valve for a water heater, comprising a hollow valve body shell 1, the valve body shell 1 is penetrating and fixedly connected with a hot water pipe 101 and a cold water pipe 102, and a check valve is arranged inside the hot water pipe 102, allowing only hot water Water enters the pressurization chamber 2 from the hot water pipe 101 and cannot flow back. One end of the hot water pipe 101 located inside the valve housing 1 is fixedly connected to the pressurization chamber 2, and the cold water pipe 102 is located at one end of the valve housing 1. The water mixing pipe 10 is fixedly connected with the bottom wall of the pressurization chamber 2, and the water mixing pipe 10 is fixedly connected with the bottom wall of the valve body shell 1. The pressurization chamber 2 is connected with the rotating shaft 3 through the rotation of the bearing, and the rotating shaft 3 runs through and extends to the cold water....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com