Modular structure of open-frame gasifier system

An open-frame gasifier, modular technology, applied in the pipeline system, building structure support, building structure support, etc., can solve the problems of high service labor costs, high precision requirements for concrete tank civil construction, long installation period, etc. Achieve the effects of convenient on-site installation and subsequent maintenance, shortening the on-site construction period, and improving the modularization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

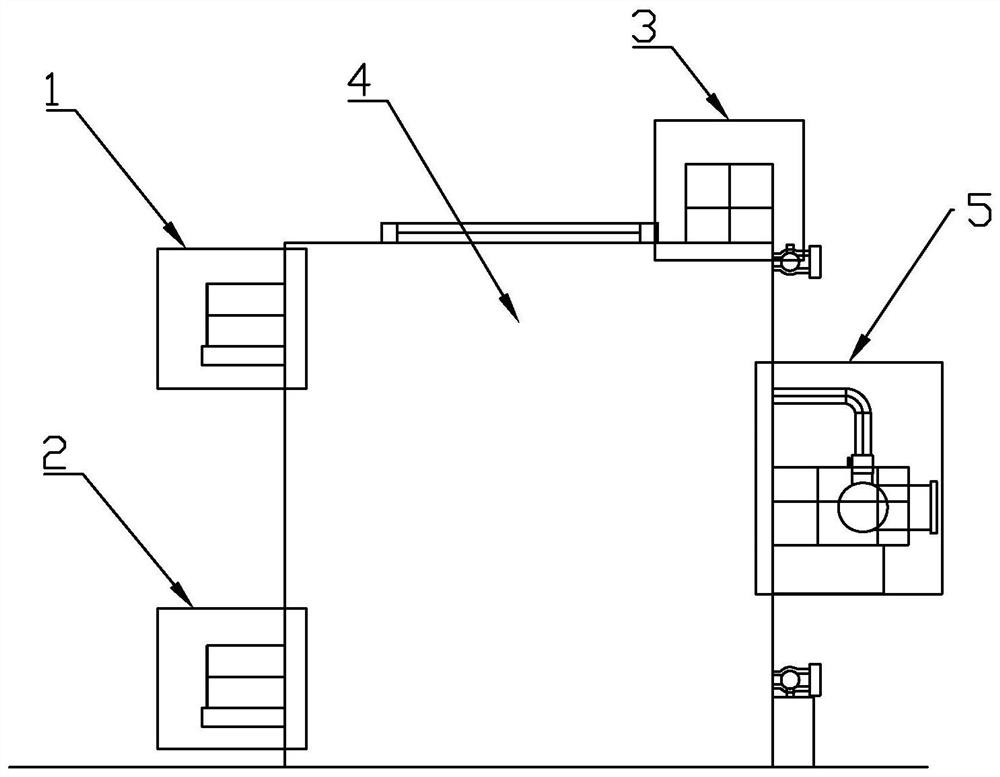

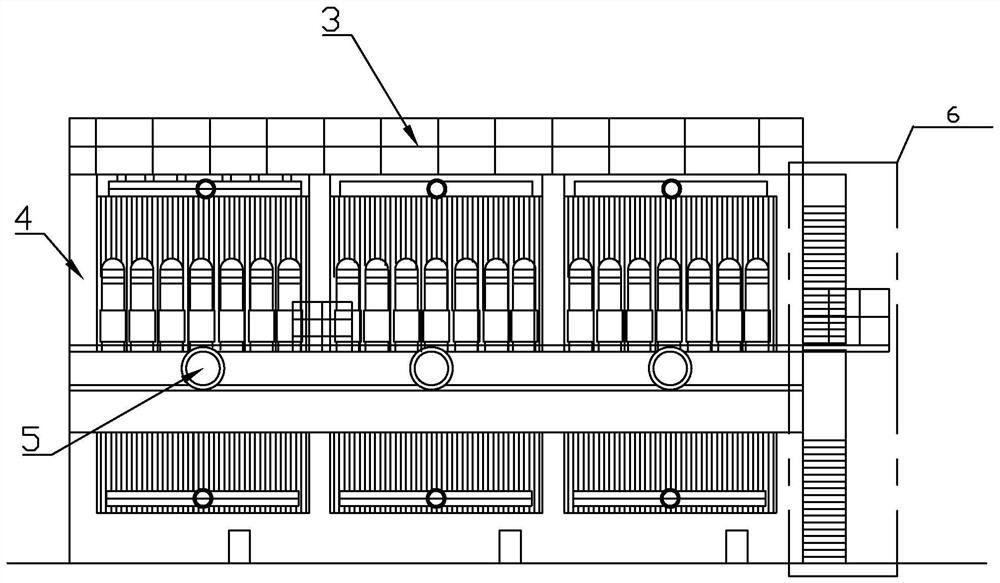

[0042] like figure 1 , figure 2 As shown, the modular structure of an open-frame gasifier system provided by the present invention mainly includes an upper maintenance platform module 1, a lower observation platform module 2, a top walkway module 3, a heat exchange plate module 4, and a seawater pipeline adjustment platform module 5 and the ladder platform module 6, wherein:

[0043] The upper maintenance platform module 1 is arranged on one side of the heat exchange plate module 4, as image 3 As shown, it mainly includes a steel structure maintenance platform 11 and a maintenance guardrail 12. The steel structure maintenance platform 11 can be used by maintenance personnel to walk through, and the maintenance guardrail 12 is fixed on one side of the steel structure maintenance platform 11 to protect the maintenance personnel. ;

[0044] The lower observation platform module 2 is arranged on one side of the heat exchange plate module 4, and is preferably located below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com