Preparation method for loading CsPbX3 on surface of long-afterglow luminescent material

A long-lasting luminescent and surface-loaded technology, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problem of single luminescent color, and achieve the effects of simple synthesis process, easy mass synthesis, and high long-lasting luminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

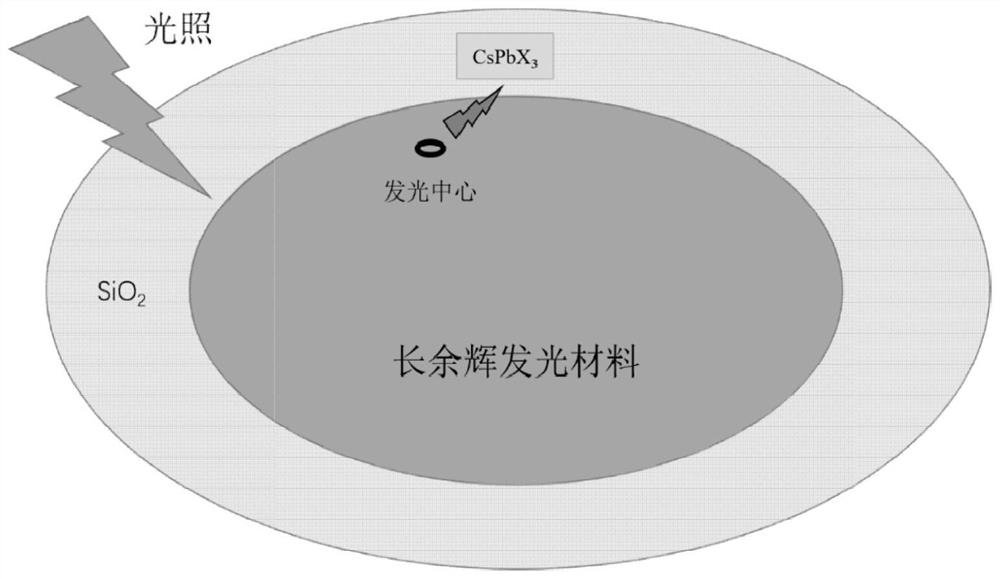

[0040]CsPbX loaded on the surface of a long afterglow luminescent material of the present invention 3 The preparation method is specifically implemented according to the following steps:

[0041] Step 1, mix 0.4mmolCsBr and 0.4mmolPbBr 2 , and 0.8ml oleic acid (OA), 0.2ml oleylamine (OAm) were completely dissolved in 10ml of dimethylformamide (DMF) solvent, magnetically stirred for 30min to obtain a clear solution after dissolution;

[0042] Step 2, drop 0.5ml of the clear solution into 10ml of toluene, stir to obtain sample a, and the stirring speed is 800rpm;

[0043] Step 3, 0.5ml of sample a, 0.1ml of tetraethyl orthosilicate (TEOS), 0.1g of Sr 2 MgSi 2 o 7 : Eu 2+ , Dy 3+ Add it into toluene, adjust the pH to 8, stir for 30min; the stirring speed is 500rpm;

[0044] Step 4, the turbid solution obtained in step 3 is centrifuged, washed 3 times with toluene, and dried to obtain CsPbX 3 Surface-loaded long-lasting luminescent materials.

[0045] The centrifugal spee...

Embodiment 2

[0048] CsPbX loaded on the surface of a long afterglow luminescent material of the present invention 3 The preparation method is specifically implemented according to the following steps:

[0049] Step 1, mix 0.4mmolCsCl and 0.4mmolPbCl 2 , and 0.8ml oleic acid (OA), 0.2ml oleylamine (OAm) were completely dissolved in 10ml of dimethylformamide (DMF) solvent, and magnetically stirred for 30min to obtain a clear solution after dissolution;

[0050] Step 2, drop 0.5ml of the clear solution into 10ml of toluene, stir to obtain sample a, and the stirring speed is 800rpm;

[0051] Step 3, 0.5ml of sample a, 0.1ml of tetraethyl orthosilicate (TEOS), 0.1g of Sr 2 MgSi 2 o 7 : Eu 2+ , Dy 3+ Add it into toluene, adjust the pH to 9, stir for 30min; the stirring speed is 500rpm;

[0052] Step 4, centrifuge the turbid solution obtained in step 3, wash with toluene several times, and dry to obtain CsPbX 3 Surface-loaded long-lasting luminescent materials.

[0053] The centrifugal s...

Embodiment 3

[0056] CsPbX loaded on the surface of a long afterglow luminescent material of the present invention 3 The preparation method is specifically implemented according to the following steps:

[0057] Step 1, mix 0.4mmolCsI and 0.4mmolPbI 2 , and 0.8ml oleic acid (OA), 0.2ml oleylamine (OAm) were completely dissolved in 10ml of dimethylformamide (DMF) solvent, and magnetically stirred for 30min to obtain a clear solution after dissolution;

[0058] Step 2, drop 0.5ml of the clear solution into 10ml of toluene, stir to obtain sample a, and the stirring speed is 800rpm;

[0059] Step 3, 0.5ml of sample a, 0.1ml of tetraethyl orthosilicate (TEOS), 0.1g of Sr 2 MgSi 2 o 7 : Eu 2+ , Dy 3+ Add it into toluene, adjust the pH to 10, stir for 30min; the stirring speed is 500rpm;

[0060] Step 4, centrifuge the turbid solution obtained in step 3, wash with toluene several times, and dry to obtain CsPbX 3 Surface-loaded long-lasting luminescent materials.

[0061] The centrifugal sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com