Adjustable single-roll crusher

A single roll crusher, adjustable technology, applied in grain processing, etc., can solve the problems of wasting time, the distance between the crushing plate and the crushing roller is not adjustable, and the replacement process is troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

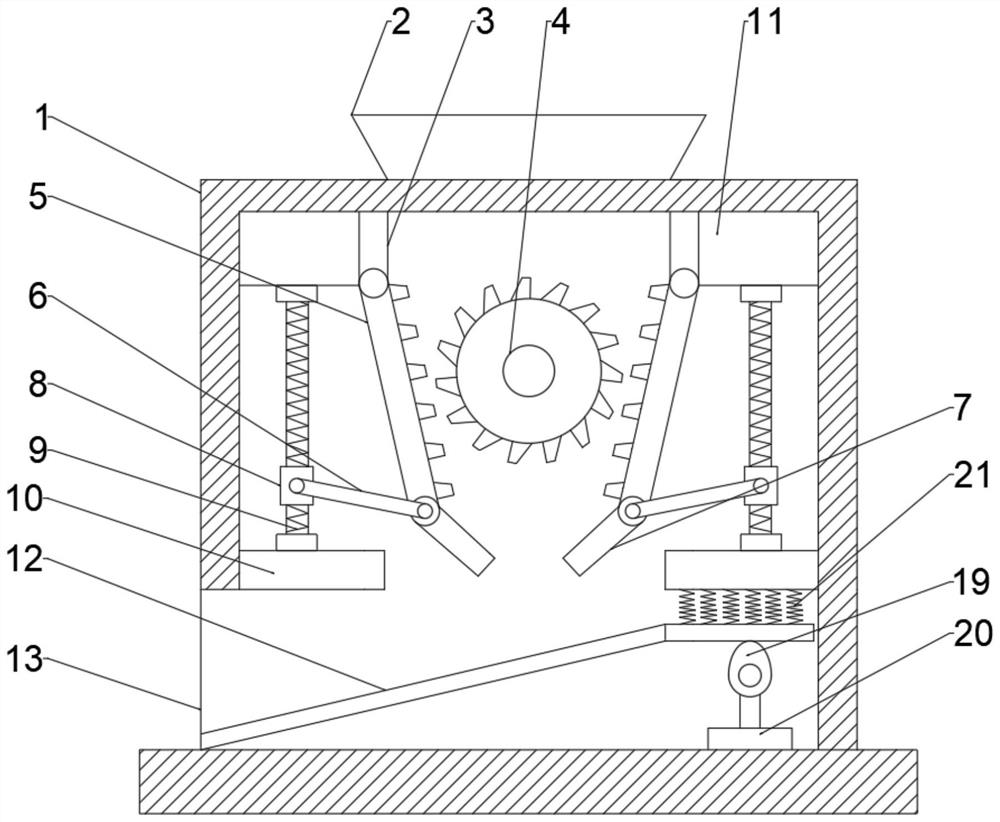

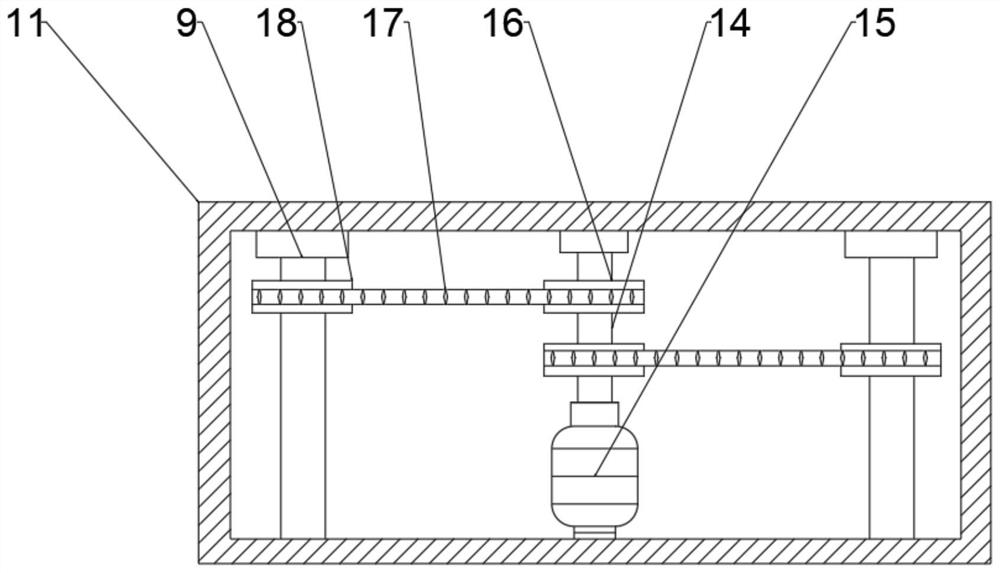

[0021] see Figure 1~3 , in Embodiment 1 of the present invention, an adjustable single-roll crusher includes a machine body 1, which includes a crushing part and a discharge part, and the crushing part is arranged on the upper part of the machine body 1, including two fixed plate 3, the fixed plate 3 is fixed on the top of the body 1, the two fixed plates 3 are hinged with a broken plate 5, the broken plate 5 can rotate on the fixed plate 3, and the middle part of the two broken plates 5 is provided with The crushing wheel 4, the crushing wheel 4 and the crushing plate 5 are provided with crushing teeth, through the rotation of the crushing wheel 4 and the crushing plate 5, the material is crushed, and the side of the crushing plate 5 far away from the crushing wheel 4 is connected with an adjustment mechanism , used to adjust the distance between the crushing plate 5 and the crushing wheel 4, the side of the crushing plate 5 away from the crushing wheel 4 is also provided wi...

Embodiment 2

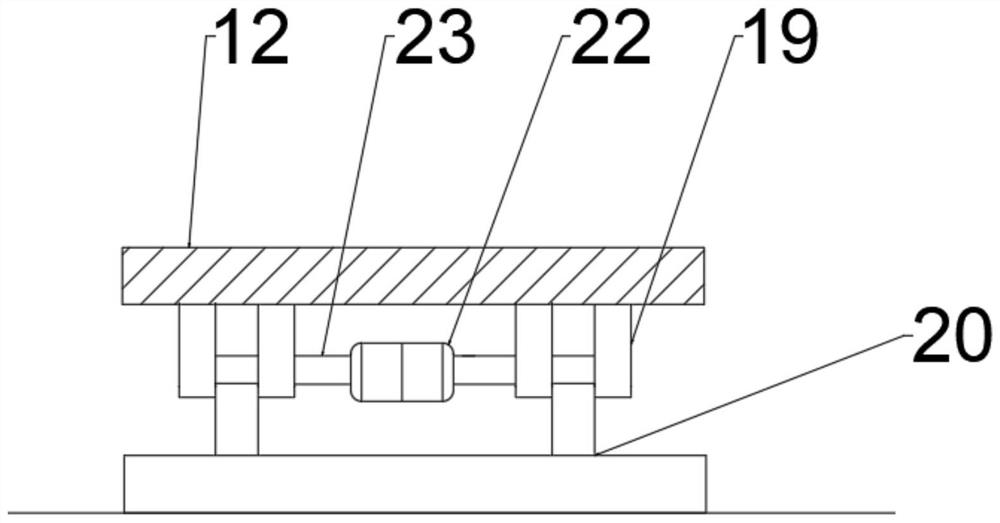

[0026] see Figure 1~3 , the high end of the slide table 12 is connected with the fixed table 10 by a spring 21, so that the slide table 12 can vibrate up and down, and the lower side of the high end of the slide table 12 is provided with two convex wheels 19, and the convex wheel 19 Used to drive the slide table 12 to vibrate up and down, the convex wheel 19 is fixed on the bottom of the body 1 through the base 20, a b motor 22 is arranged between the two convex wheels 19, and the two ends of the b motor 22 rotate Connected with the b rotating shaft 23, the b motor 22 is used to drive the b rotating shaft 23 to rotate, the other end of the b rotating shaft 23 is connected to the cam wheel 19, and the b rotating shaft 23 is used to drive the cam wheel 19 to rotate.

[0027] Further, the body 1 is also provided with a feed port 2 and a discharge port 13, the feed port 2 is arranged directly above the crushing wheel 4, the feed port 2 is used for feeding materials into the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com