Production equipment of emulsifiable concentrate botanical composite pesticide special for green tea trees

A compound pesticide and production equipment technology, applied in the direction of mixer, chemical/physical process, dissolution, etc., can solve the problems of affecting production efficiency, low efficiency, high labor cost, etc., achieve rapid and sufficient mixing of raw materials, improve the efficiency of discharging, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

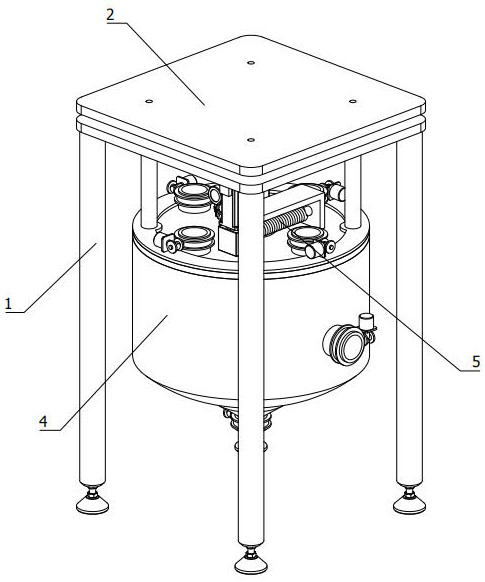

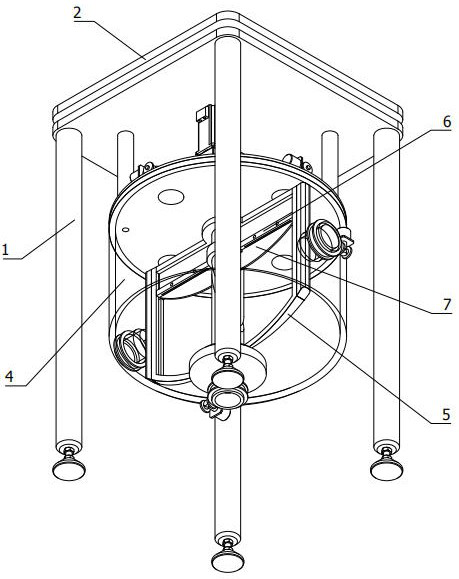

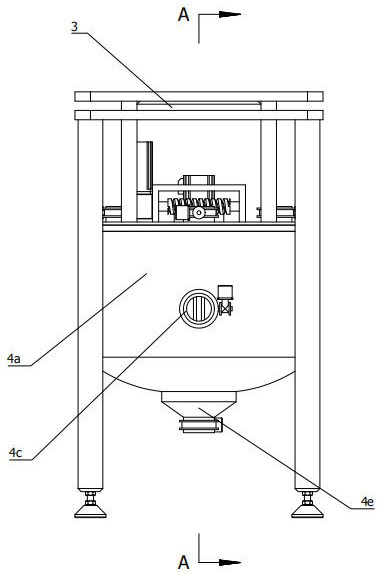

[0076] Such as Figure 1 to Figure 4 Shown, a kind of production equipment of emulsifiable plant source compound pesticide special for green tea tree, comprises frame 1, hanger 2, electronic scale 3, mixing tank 4, rotating mechanism 5, reciprocating mechanism 6 and stirring blade 7;

[0077] The hanger 2 is installed on the top of the frame 1 in a gap fit with the frame 1, and is used to suspend the mixing tank 4;

[0078] The electronic scale 3 is installed between the top of the frame 1 and the hanger 2, and is used to monitor the overall weight of the mixing tank 4 and then control the quantitative feeding of raw materials;

[0079] The mixing tank 4 is installed at the bottom of the hanger 2 to stir t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com