Stirrer for electric heating stirring tank

A mixing tank and agitator technology, which is applied in the direction of mixer accessories, chemical instruments and methods, mixers with rotating containers, etc., can solve the problems of small mixing area, low mixing efficiency, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

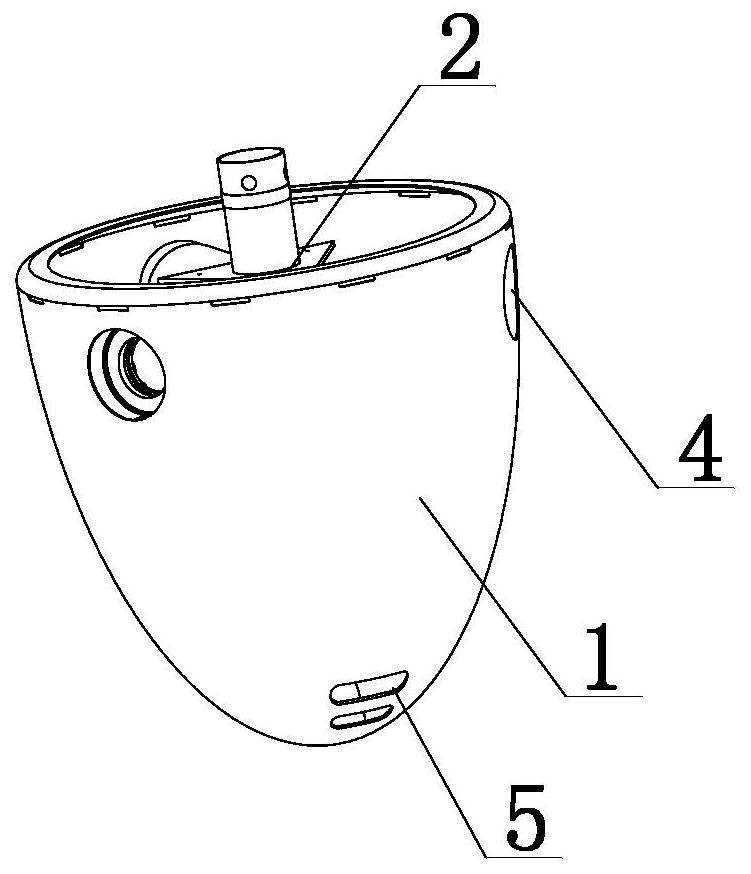

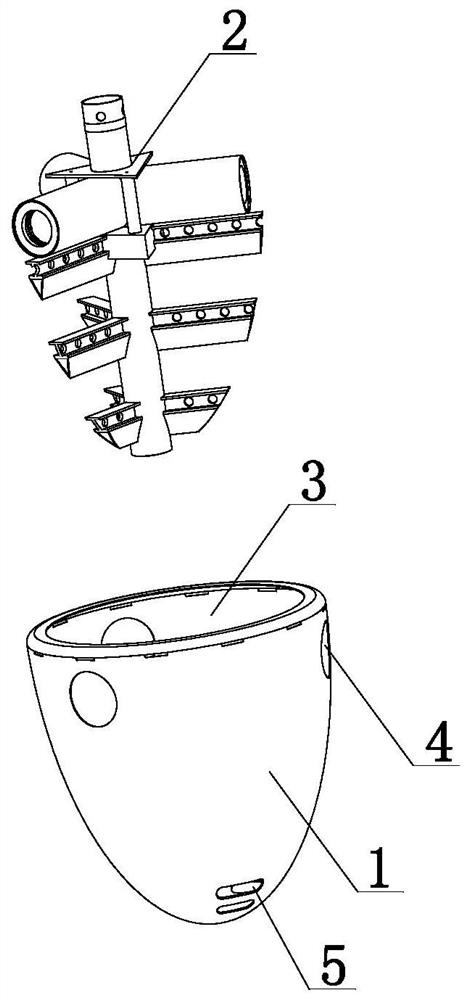

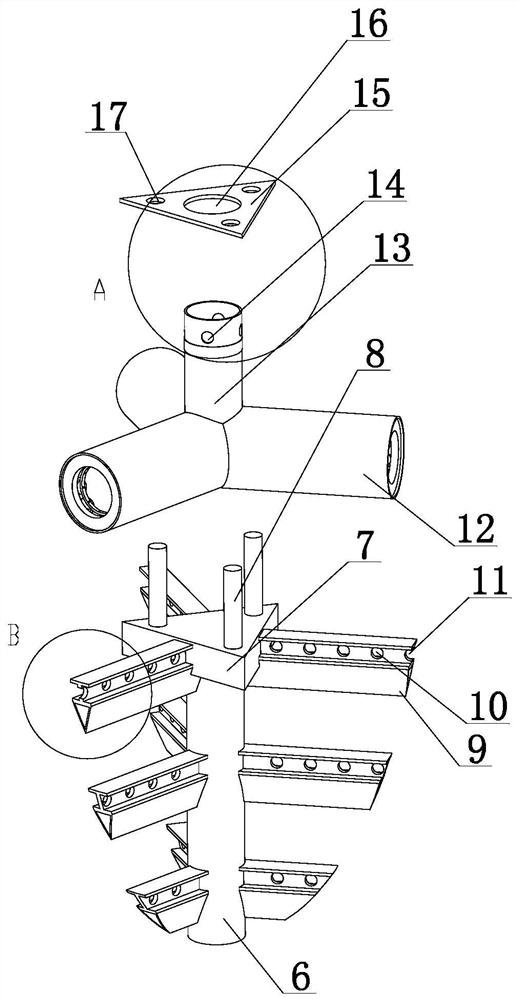

[0018] like Figure 1 to Figure 5 Shown, a kind of stirrer that is used for electric heating stirring tank, comprises mixing drum 1, and the interior of stirring drum 1 is provided with stirring mechanism 2, and stirring drum 1 is conical shape, and the inside of stirring drum 1 is provided with stirring chamber 3, The top of the mixing drum 1 is an open structure; the top edge of the mixing drum 1 is provided with several positioning holes 4, and the bottom of the mixing drum 1 is provided with an opening 5; the stirring mechanism 2 includes a stirring tube 6, and the end of the mixing tube 6 is provided with a stirring Block 7, stirring block 7 is provided with several positioning shafts 8; Positioning tube 12, the outer end of positioning tube 12 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com