Novel zeolite deodorization bead and preparation method thereof

A zeolite and deodorizing technology, which is applied in the field of new zeolite deodorizing beads and its preparation, can solve the problems of low deodorization efficiency, poor stability, poor durability, etc., to reduce material costs, facilitate the diffusion of internal deodorization functions, The effect of convenient secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

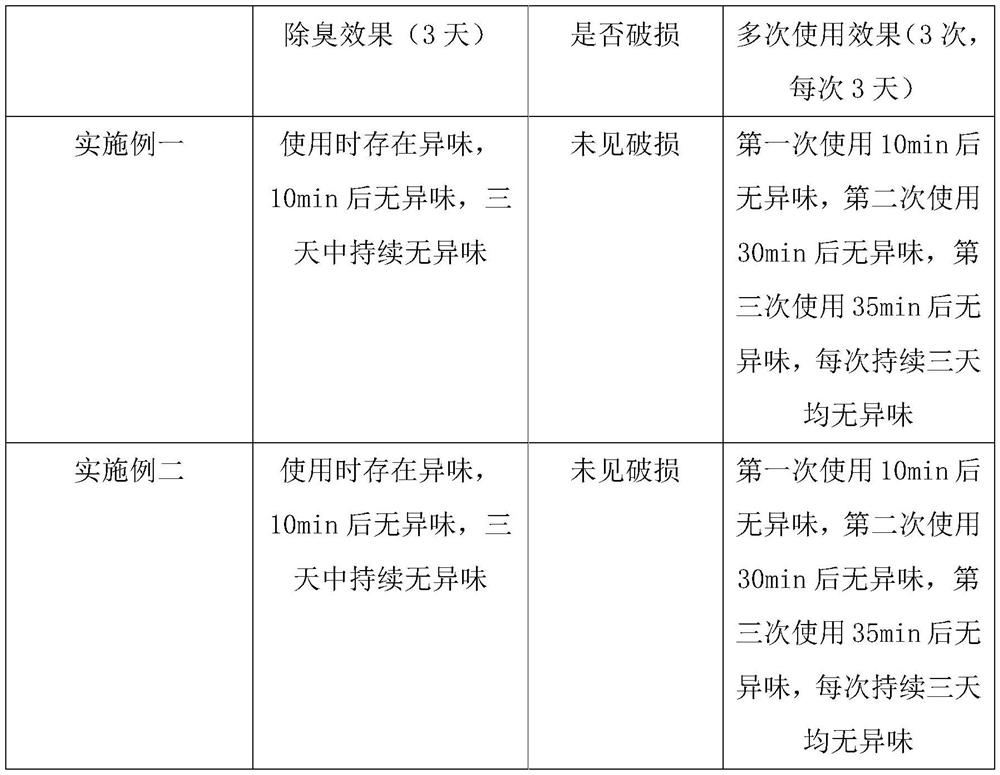

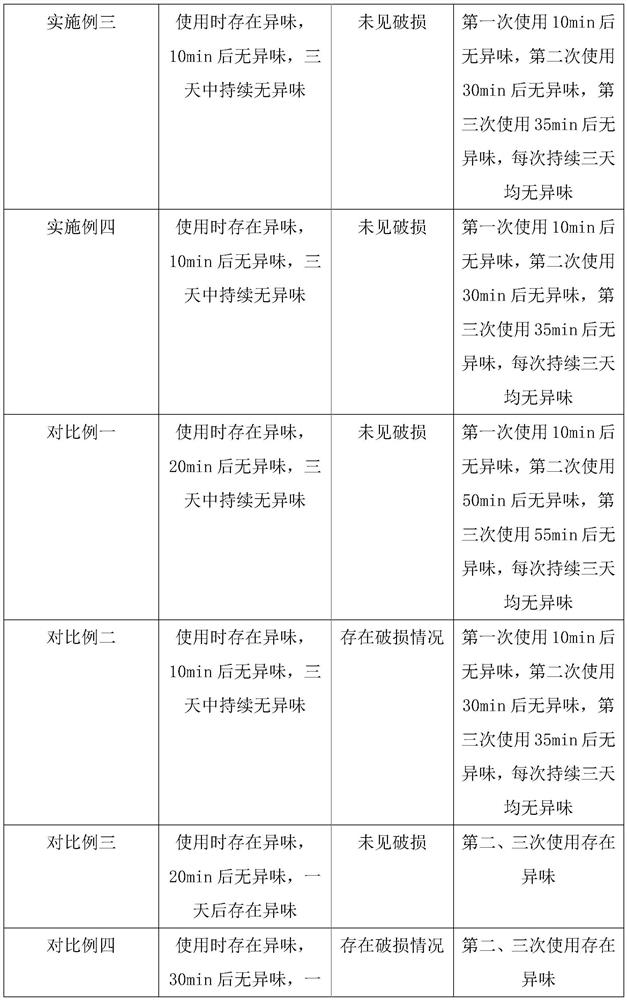

Examples

Embodiment 1

[0028] A new type of zeolite deodorizing beads proposed by the present invention comprises the following components in parts by weight: 80 parts of zeolite, 140 parts of sodium polyacrylate, 30 parts of cetylpyridinium chloride, 2 parts of fennel, 10 parts of terpene, support 150 parts of structure, 40 parts of deodorant and 20 parts of anti-wear agent.

[0029] Among them, the supporting structure is to heat the organic raw materials to 400°C under the condition of isolating the air, and then react with the gas, the surface is eroded, and a structure with developed micropores is formed. The organic raw materials include fruit shells, coal, wood, and the gas reaction step Including: firstly, in a 5% H2 / Ar atmosphere, and keep it for 4h, then cool to room temperature; then switch to air atmosphere, raise the temperature to 200°C at a rate of 1°C / min, and keep it for 2h, then cool to room temperature; finally, Switch to a nitrogen atmosphere, raise the temperature to 800°C at a ...

Embodiment 2

[0037] A new type of zeolite deodorizing beads proposed by the present invention comprises the following components in parts by weight: 85 parts of zeolite, 160 parts of sodium polyacrylate, 35 parts of cetylpyridinium chloride, 4 parts of fennel, 20 parts of terpene, support 170 parts of structure, 50 parts of deodorant and 25 parts of anti-wear agent.

[0038] Among them, the supporting structure is to heat the organic raw materials to 400°C under the condition of isolating the air, and then react with the gas, the surface is eroded, and a structure with developed micropores is formed. The organic raw materials include fruit shells, coal, wood, and the gas reaction step Including: firstly, in a 5% H2 / Ar atmosphere, and keep it for 4h, then cool to room temperature; then switch to air atmosphere, raise the temperature to 200°C at a rate of 1°C / min, and keep it for 2h, then cool to room temperature; finally, Switch to a nitrogen atmosphere, raise the temperature to 800°C at a ...

Embodiment 3

[0046] A new type of zeolite deodorizing beads proposed by the present invention comprises the following components in parts by weight: 95 parts of zeolite, 180 parts of sodium polyacrylate, 45 parts of cetylpyridinium chloride, 5 parts of fennel, 25 parts of terpene, support 180 parts of structure, 55 parts of deodorant and 28 parts of anti-wear agent.

[0047] Among them, the supporting structure is to heat the organic raw materials to 400°C under the condition of isolating the air, and then react with the gas, the surface is eroded, and a structure with developed micropores is formed. The organic raw materials include fruit shells, coal, wood, and the gas reaction step Including: firstly, in a 5% H2 / Ar atmosphere, and keep it for 4h, then cool to room temperature; then switch to air atmosphere, raise the temperature to 200°C at a rate of 1°C / min, and keep it for 2h, then cool to room temperature; finally, Switch to a nitrogen atmosphere, raise the temperature to 800°C at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com