Seeder discharging device and using method thereof

A seeder and hopper technology, which is applied in the field of seeder unloading device, can solve problems such as easy dust splashing, affecting normal feeding, and blocking land sowing, so as to achieve good contact effect and ensure seeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the examples.

[0046] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

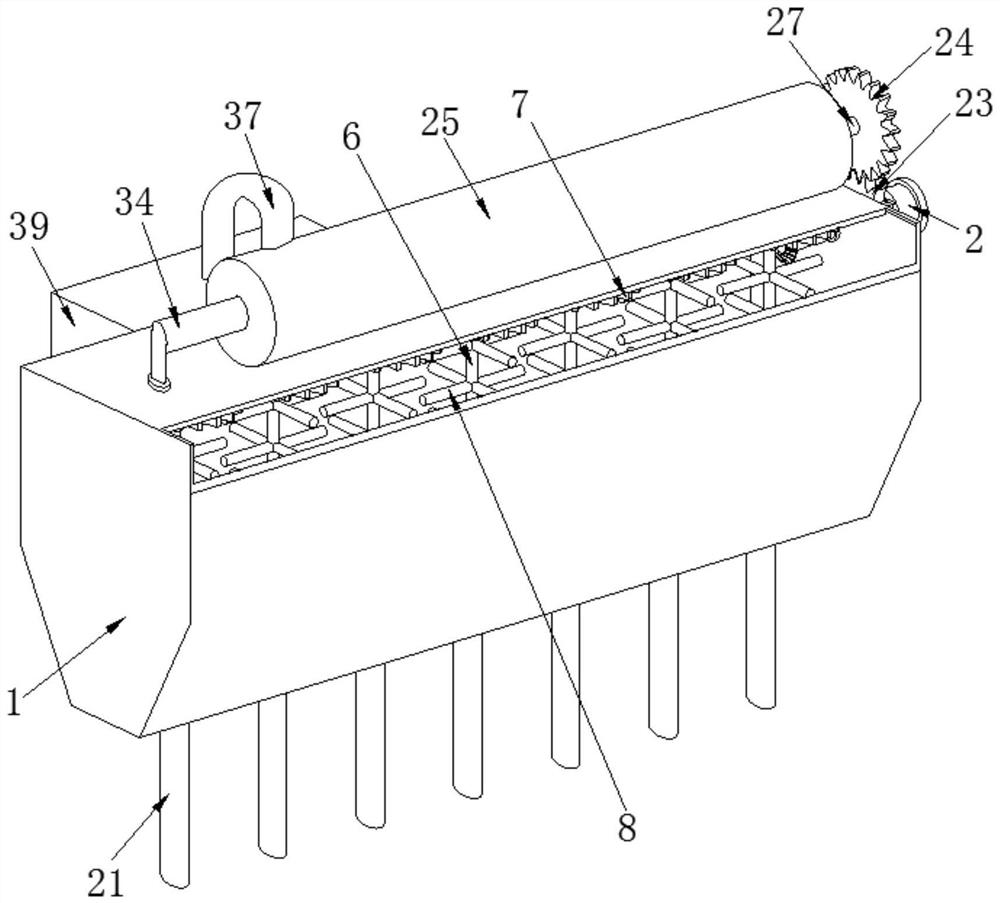

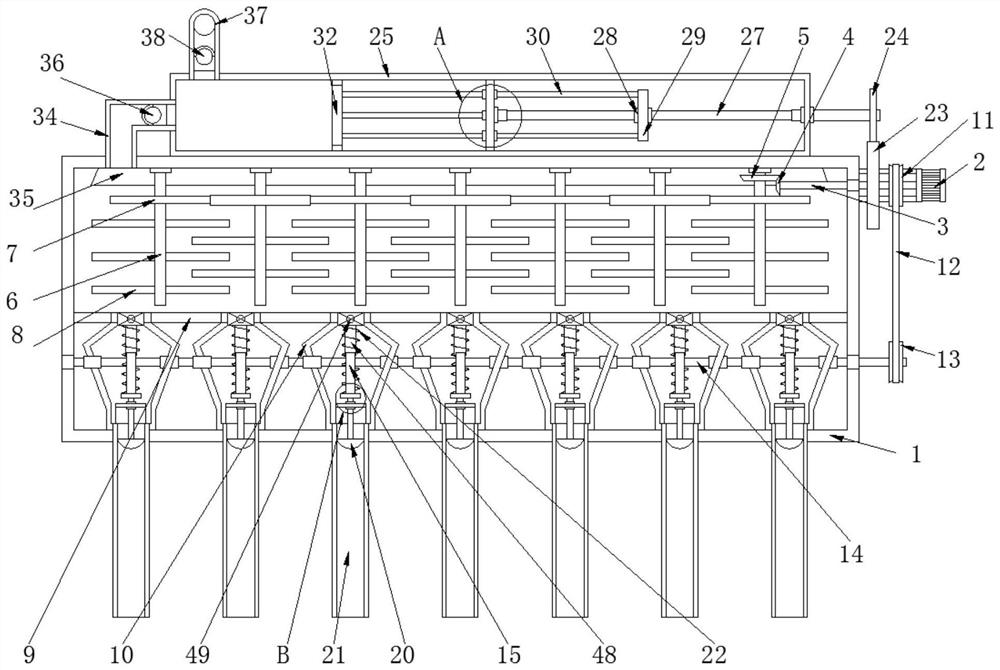

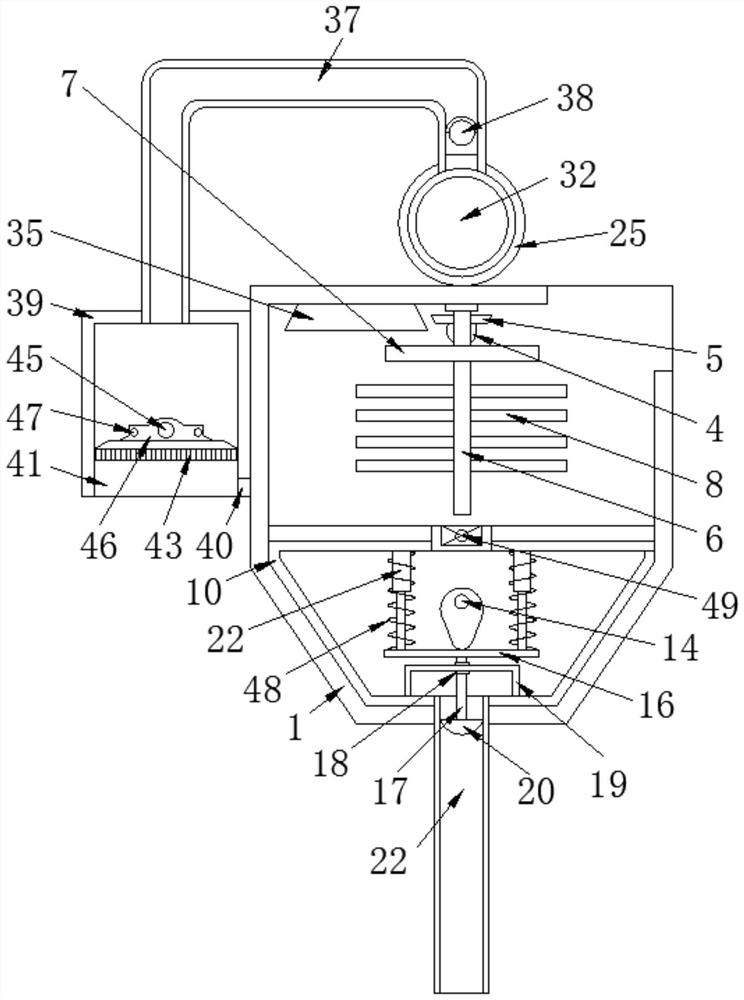

[0047] see Figure 1-8 , the present invention provides a seeder feeding device, comprising a lower hopper 1, a stirring unit is installed inside the lower hopper 1, a motor-2 is installed on the right side of the lower hopper 1, and a motor-2 is fixed on the output shaft of the motor-2 Rotating shaft one 3, rotating shaft one 3 runs through and extends to the inside of the lower hopper 1 and is equipped with a bevel gear one 4, the bevel gear one 4 is meshed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com