Planetary carrier

A planetary carrier and pinion technology, which is applied to belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of misinstallation of pinions, cost barriers of pinions, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described based on the drawings. In the embodiment, an example in which the planetary carrier 4 is applied to the single-pinion type planetary gear mechanism 1 is described as an example, but the planetary carrier 4 may be applied to, for example, a double-pinion type planetary gear mechanism or the like. . In addition, in the embodiment, an example in which the planetary gear mechanism 1 is applied to a driving device of an automobile is described as an example, but the planetary gear mechanism 1 may be applied to other devices.

[0030] [Planetary gear mechanism]

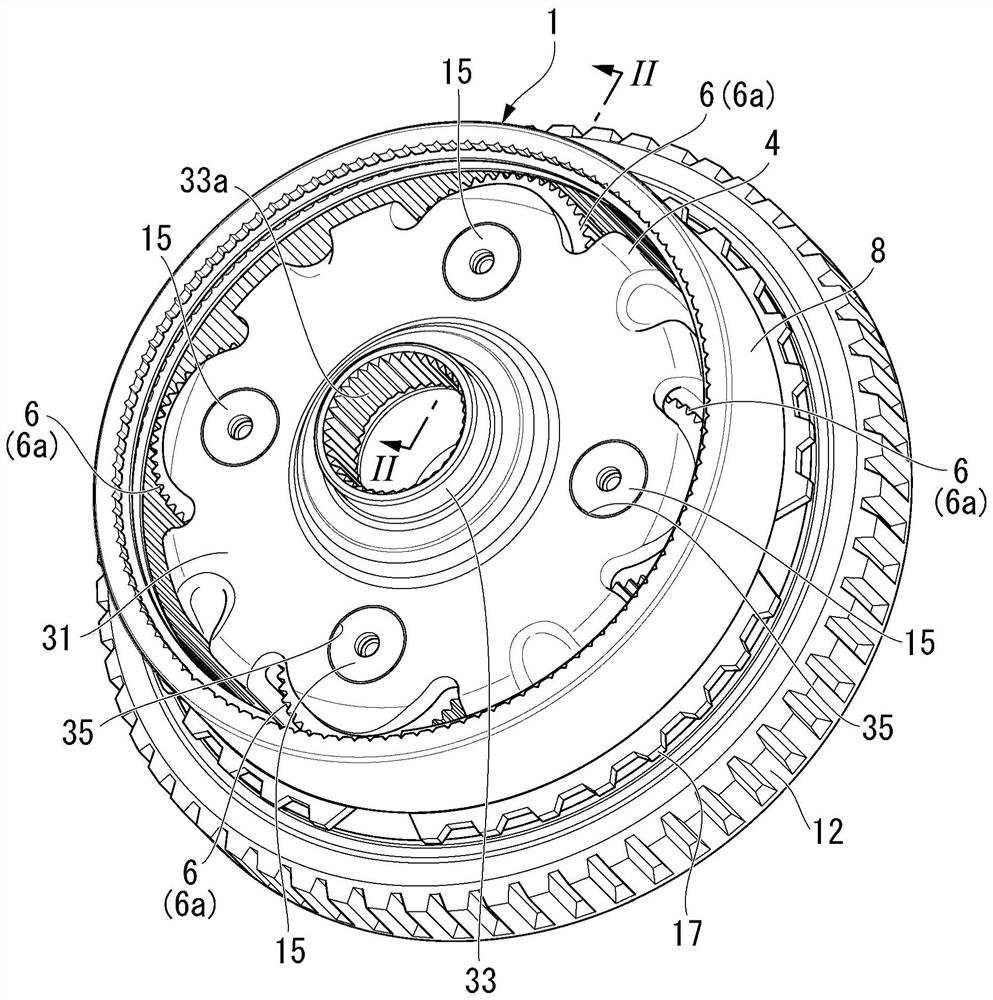

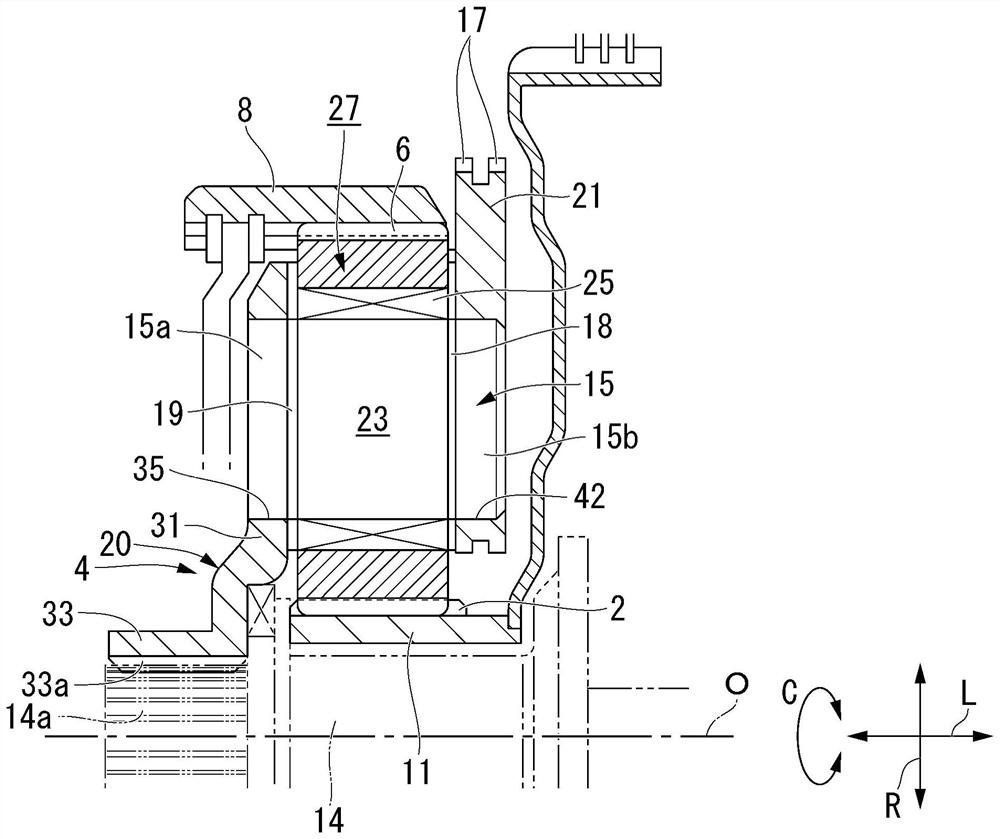

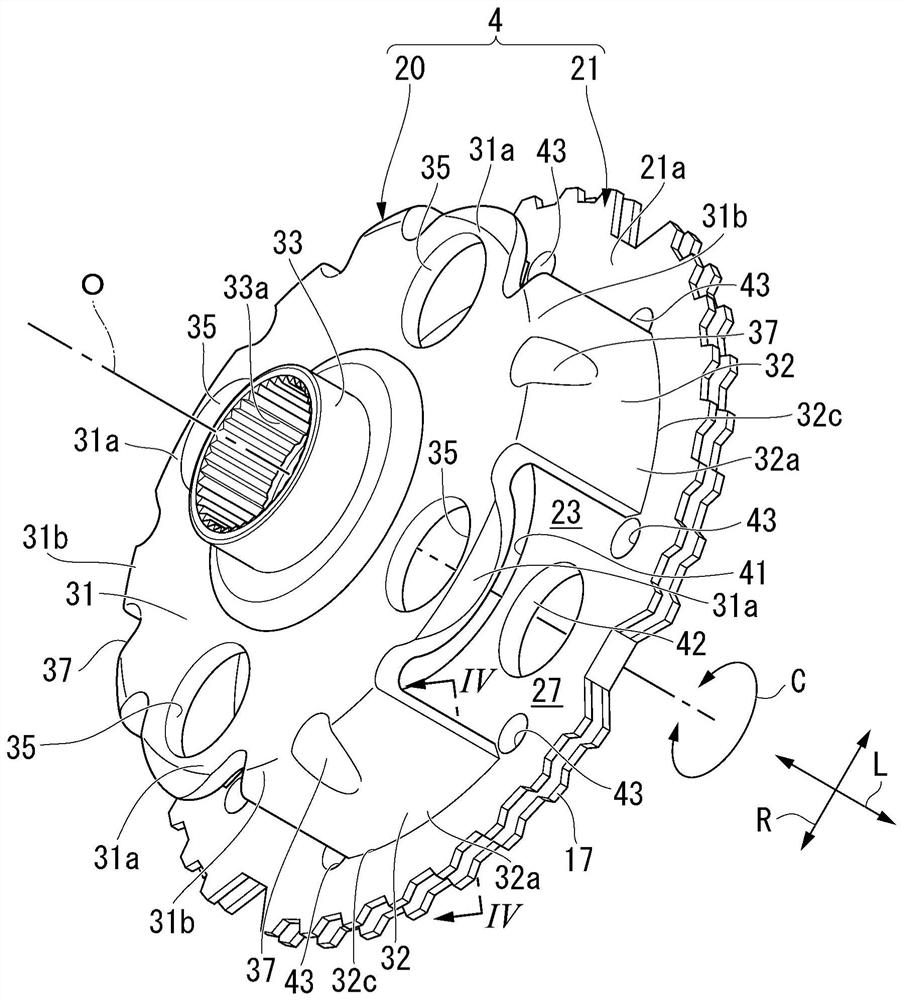

[0031] figure 1 It is a perspective view of the planetary gear mechanism 1 . figure 2 is along figure 1 Sectional view of line II-II.

[0032] Such as figure 1 , figure 2 As shown, the planetary gear mechanism 1 is equipped, for example, in a drive device of a vehicle. The planetary gear mechanism 1 includes a sun gear 2 , a carrier 4 , a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com