Oil and rust remover and preparation method and application thereof

A technology of rust remover and additives, which is applied in the field of oil remover and rust remover and its preparation, can solve the problems of too long use time, human carcinogenicity, and large corrosion of metal substrates, etc., and achieve the effect of simple processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

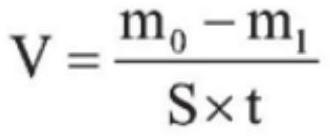

Method used

Image

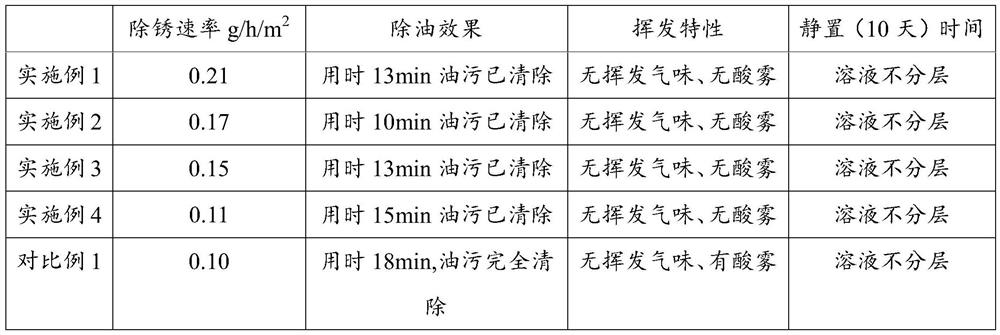

Examples

Embodiment 1

[0045] The rust remover that the embodiment of the present invention provides is by weight 3% of the concentrated sulfuric acid of purity 98%, 8% of the phosphoric acid of purity 85%, 2% of the concentrated nitric acid of purity 98%, the hydrofluoric acid 1% of purity 99%, 99% citric acid 4%, 99% oxalic acid 3%, 98% 2-hydroxyphosphonoacetic acid 13%, 99% sodium fluoride 1%, 99% sodium D-gluconate 4% , 99% purity JFC 1%, 99% purity urea 2%, 99% purity ethanolamine hydrochloride 2%, 99% purity sodium dodecylbenzenesulfonate 1%, 99% purity propylene glycol butyl ether 1%, Diethanolamine with a purity of 99% and 1% of diethanolamine, fatty acid methyl ester and fatty alcohol ether sulfonated product with a purity of 70% and 1.8%, and the balance is composed of pure water.

[0046] Preparation process: Dissolve water, diethanolamine, propylene glycol butyl ether, sodium dodecylbenzenesulfonate, JFC, fatty acid methyl ester and fatty alcohol ether sulfonate in a water bath at 50°C f...

Embodiment 2

[0050] The rust remover provided by the embodiments of the present invention is 3% by weight of concentrated sulfuric acid with a purity of 98%, 8% of phosphoric acid with a purity of 85%, 2% of concentrated nitric acid with a purity of 98%, 1% of hydrofluoric acid with a purity of 99%. 99% Citric Acid 10%, Purity 99% Oxalic Acid 8%, Purity 50% Acrylic Acid 5%, Purity 98% 2-Hydroxyphosphonoacetic Acid 10%, Purity 99% Sodium Fluoride 2%, Purity 99% Sodium D-Gluconate 5%, JFC 99% Purity 1%, Ethanolamine Hydrochloride 99% Purity 2%, Sodium Dodecylbenzene Sulfonate 99% Purity 1%, Propylene Glycol Butyl Ether 99% Purity 2%, Purity 99% diethanolamine 2%, fatty acid methyl ester and fatty alcohol ether sulfonate 1.8% purity 70%, and the balance is composed of pure water.

[0051] Preparation process: Dissolve water, propylene glycol butyl ether, sodium dodecylbenzenesulfonate, JFC, fatty acid methyl ester and fatty alcohol ether sulfonate in a water bath at 50°C for 30 minutes to obt...

Embodiment 3

[0055] The rust remover provided by the embodiments of the present invention is 3% by weight of concentrated sulfuric acid with a purity of 98%, 2% of concentrated nitric acid with a purity of 98%, 5% of phosphoric acid with a purity of 85%, 1% of hydrofluoric acid with a purity of 99%, Oxalic Acid 99% Purity 10%, Acrylic Acid 50% Purity 10%, 2-Hydroxyphosphonoacetic Acid 98% Purity 8%, Sodium Fluoride 99% Purity 1%, Sodium D-Gluconate 99% Purity 3% , 99% purity JFC 1%, 99% purity urea 2%, 99% purity ethanolamine hydrochloride 2%, 99% purity sodium dodecylbenzenesulfonate 1%, 99% purity propylene glycol butyl ether 1%, 2% of fatty acid methyl ester and fatty alcohol ether sulfonate with a purity of 70%, and the balance is composed of pure water.

[0056] Preparation process: Dissolve water, propylene glycol butyl ether, sodium dodecylbenzenesulfonate, JFC, fatty acid methyl ester and fatty alcohol ether sulfonate in a water bath at 50°C for 30 minutes to obtain liquid A;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com