Oil inlet and return pipe maintenance tool and method for diesel engine body at nuclear power station

A technology for overhauling tools and diesel engines, applied in manufacturing tools, workpiece clamping devices, etc., can solve problems such as large manpower, and achieve the effect of small pitch, self-locking, and top tightening stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

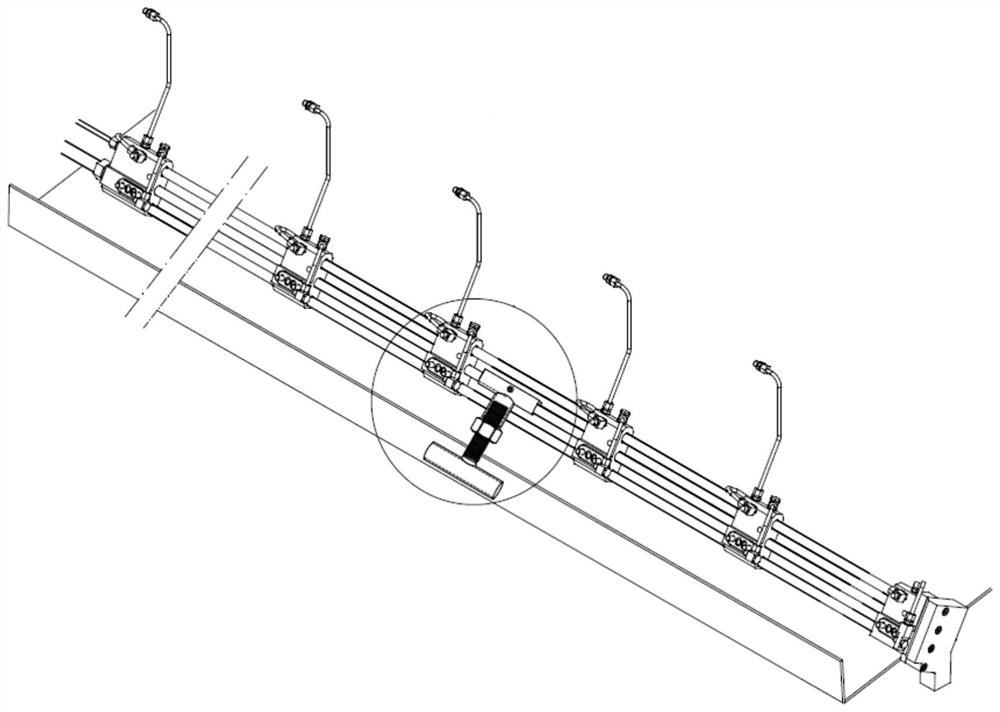

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

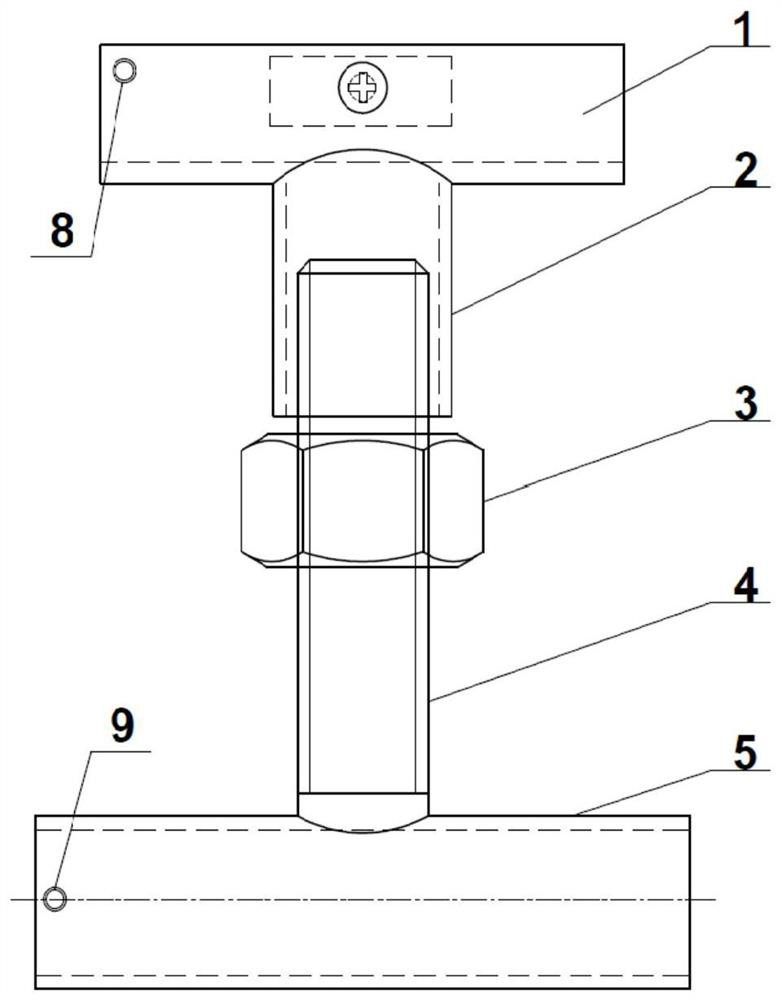

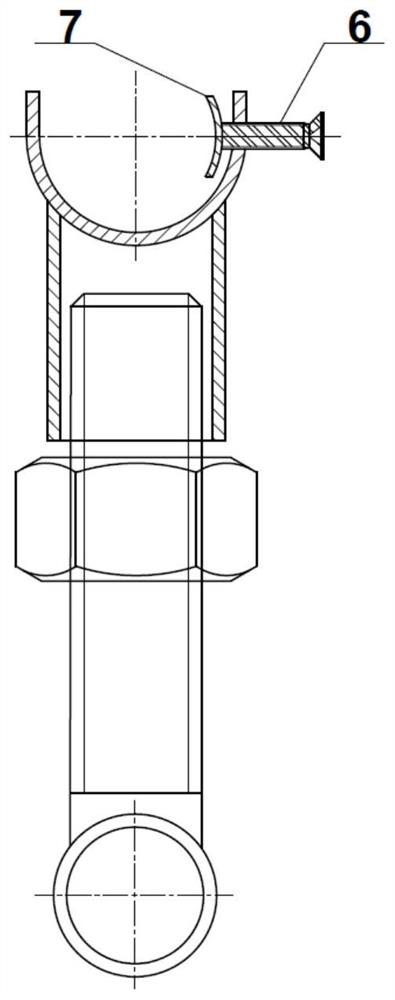

[0038] like figure 1 and figure 2 As shown, the present invention provides a maintenance tool for the inlet and outlet oil pipes of a diesel engine body in a nuclear power plant. The maintenance tool includes a clamping device and a jacking device. The tightening piece 7 and the lanyard hole A8, the tightening device includes a nut 3, a bolt 4, a bottom support member 5 and a lanyard hole B9.

[0039] like figure 1 and figure 2 As shown, the clamping tube 1 and the sleeve tube 2 are welded together to form a whole, the front of the clamping tube 1 is provided with a through hole along the axial direction, and the clamping screw 6 is connected with the through hole through a threaded connection, so that the clamping screw 6 can move Connected to the card tube 1, the clamping screw 6 is close to the end of the card tube 1, that is, the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com