A variable electrode spacing cable arrangement for high-density resistivity method

A high-density resistivity and wire arrangement technology is applied in the field of physical earth exploration, which can solve the problems of time-consuming and laborious work efficiency and large wiring workload, and achieve the effects of simple structure, high accuracy and simple stapling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

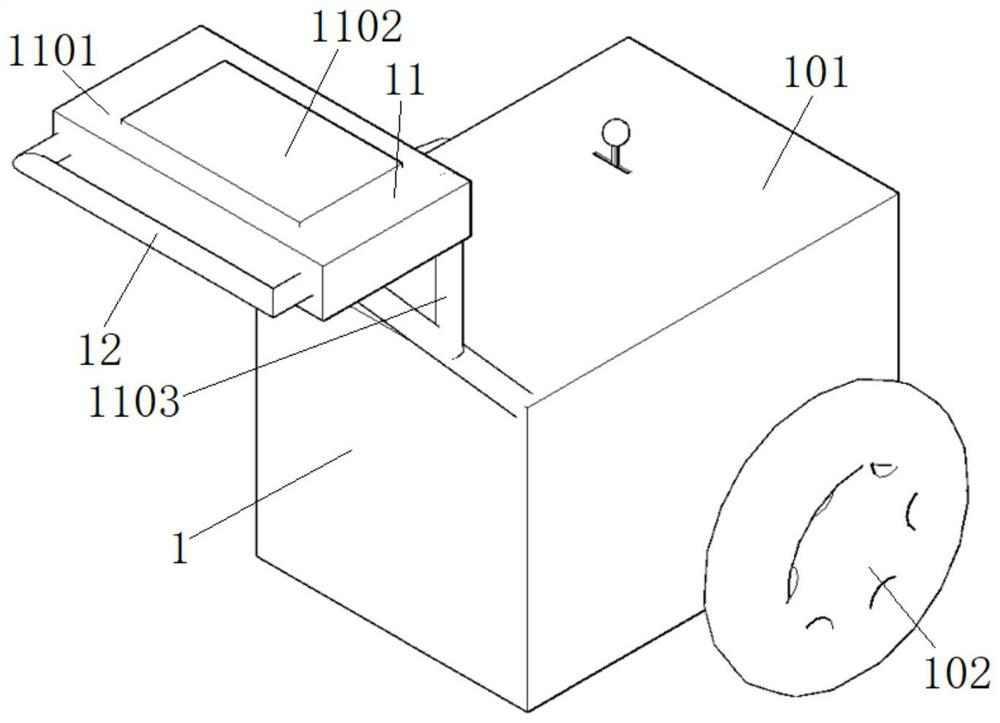

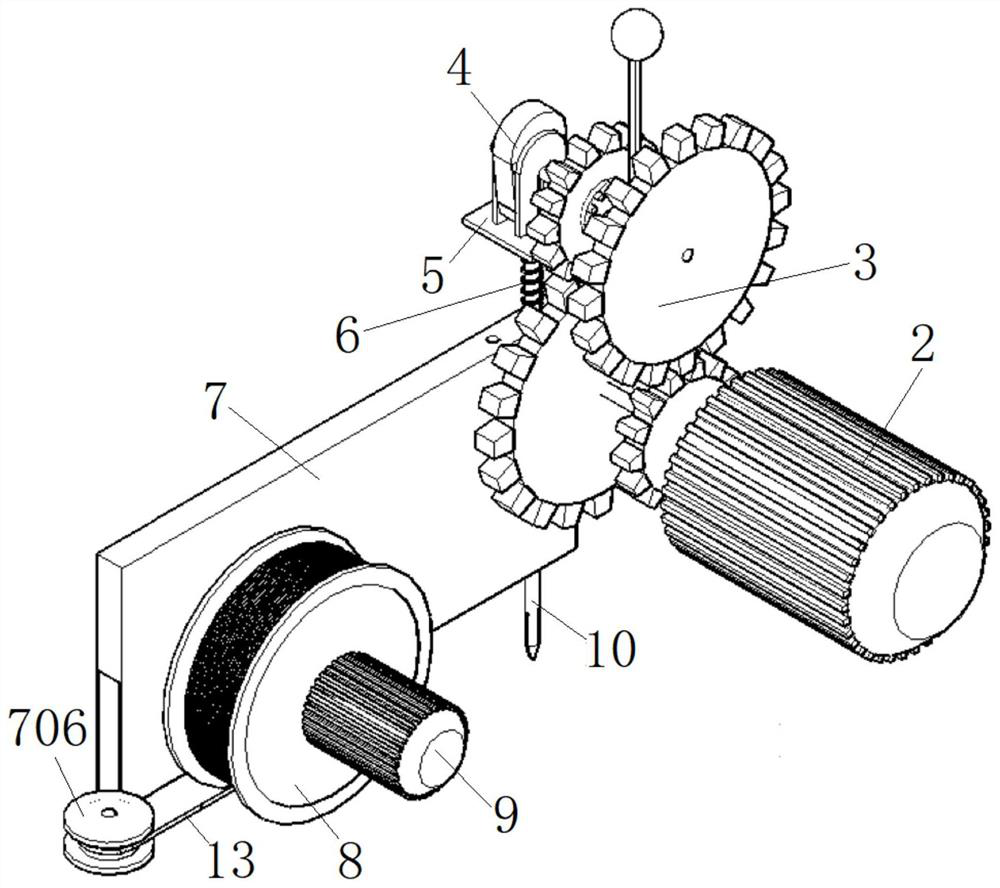

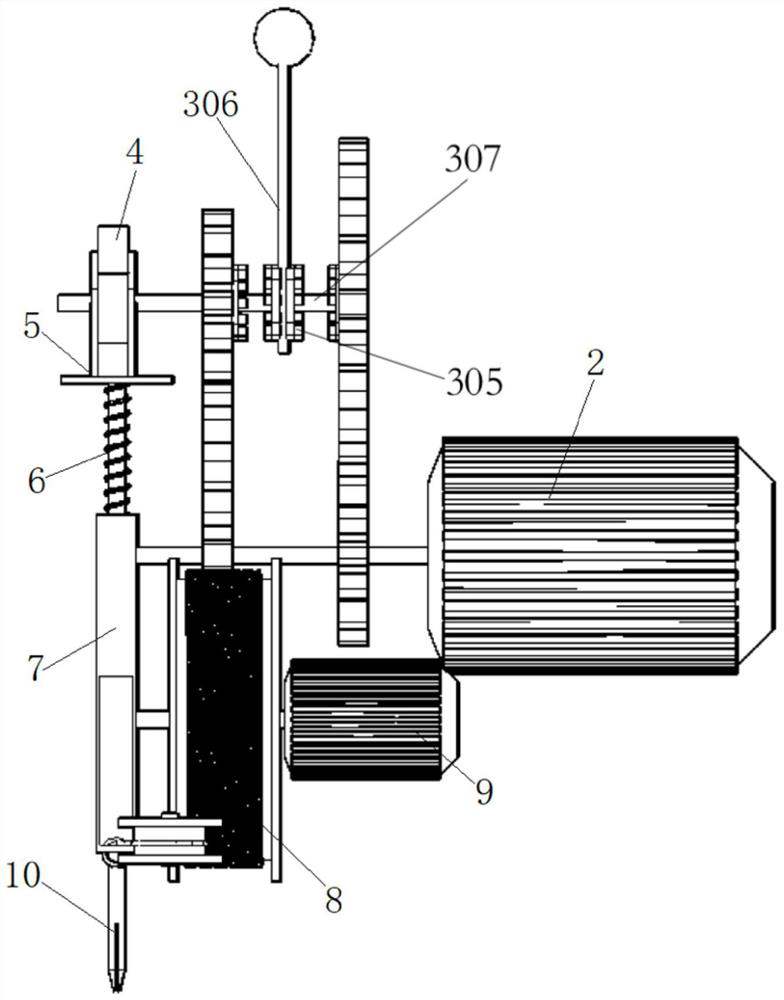

[0063] This embodiment provides a variable electrode spacing cable arrangement for high-density resistivity method, including a vehicle body and a cable arrangement unit, the cable arrangement unit is installed on the vehicle body; the circuit rack in the vehicle body is connected to the compartment and the operation Table and push rod, the operation terminal is set on the operation table, and the interior is connected with the wiring unit and the operation terminal through the built-in circuit;

[0064] The car body includes a carriage and wheels, and the wheels are installed on both sides of the carriage; the first drive motor, speed change mechanism, cam mechanism, cam base, telescopic rod, cable box, coil and second drive motor are all arranged in the carriage. The system and the push rod are arranged on the side of the carriage; in this embodiment, the size of the carriage is 0.7×0.7×1m, and the material is aluminum alloy; the circuit rack adopts a hollow cylinder, the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com