Efficient fiber-based thermoelectric energy supply material and preparation method thereof

A technology of thermoelectric materials and fiber substrates, which is applied in the manufacture/processing of thermoelectric devices, fiber processing, and parts of thermoelectric devices, etc. It can solve the problems of low power generation efficiency, power consumption of heating plates, and difficulty in carrying around, etc., to achieve long-term use Long life, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of a high-efficiency fiber-based thermoelectric energy supply material, comprising the following steps:

[0032] S1, preparing a thermoelectric solution containing a thermoelectric material;

[0033] S2. Immerse the fiber substrate in the thermoelectric solution prepared in step S1, take it out and dry it, and obtain a fiber substrate with a thermoelectric material adsorption capacity of 10% to 40%; then place electrodes on the fiber substrate On the upper and lower surfaces, a fiber-based self-generating layer is obtained;

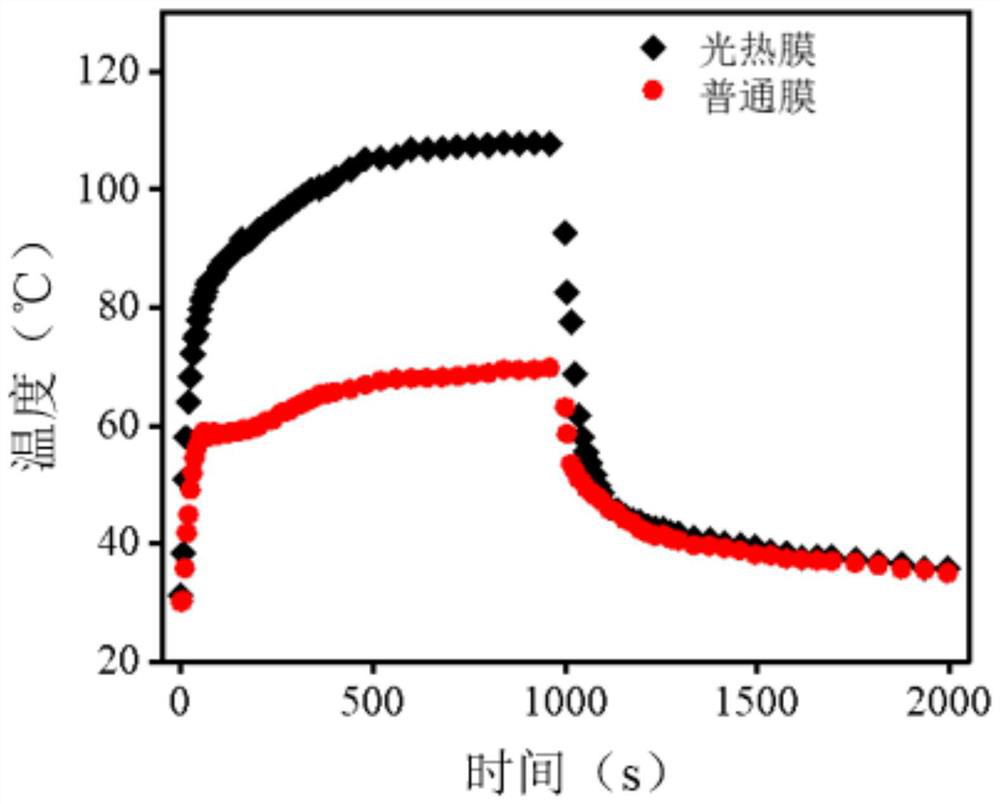

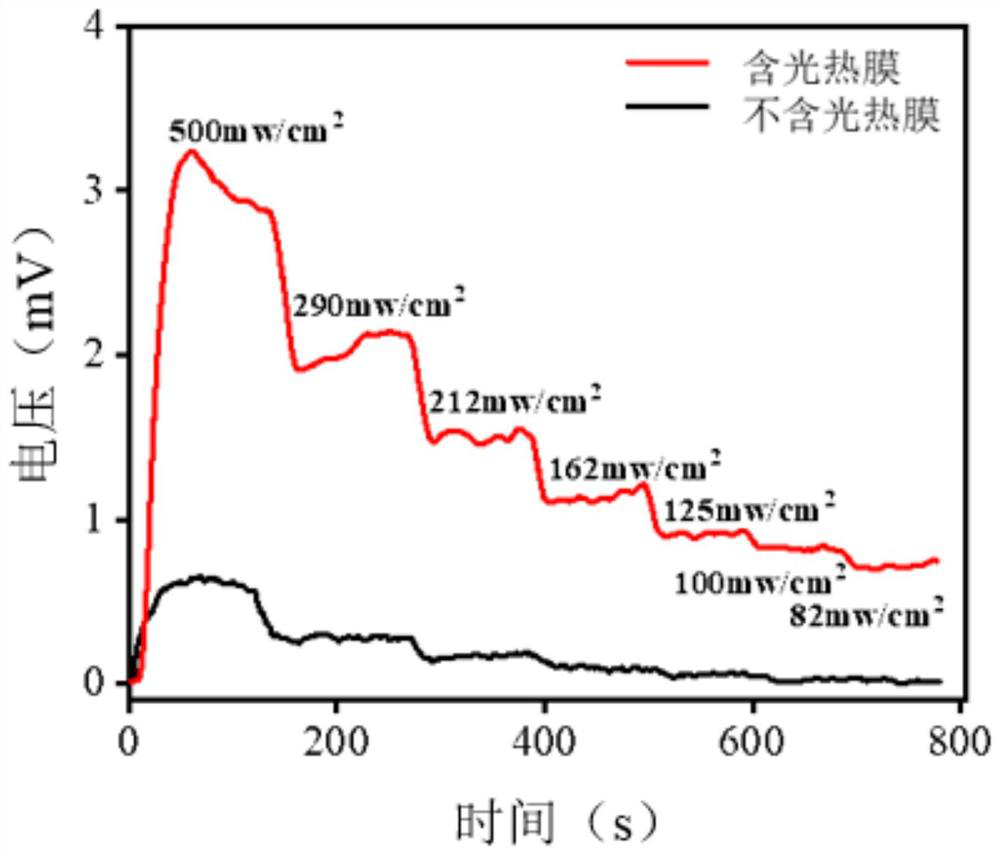

[0034]S3. Add the photothermal nanoparticles into the viscose solution containing the binding material, and mix uniformly to obtain a colloidal photothermal material; then uniformly coat the colloidal photothermal material on the fiber-based self- After the upper surface of the power generation layer is dried, the colloidal photothermal material forms a photothermal film on the upper surface to obtain a ...

Embodiment 1

[0045] This embodiment provides a method for preparing a high-efficiency fiber-based thermoelectric energy supply material, including the following steps:

[0046] S1. Add dimethyl sulfoxide and carbon nanotubes to the aqueous solution of PEDOT:PSS, and ultrasonically treat for 1 hour to mix them uniformly to obtain a thermoelectric composite solution. In the thermoelectric composite solution, the volume fraction of dimethyl sulfoxide is 5%, and the mass fraction of carbon nanotubes is 2%.

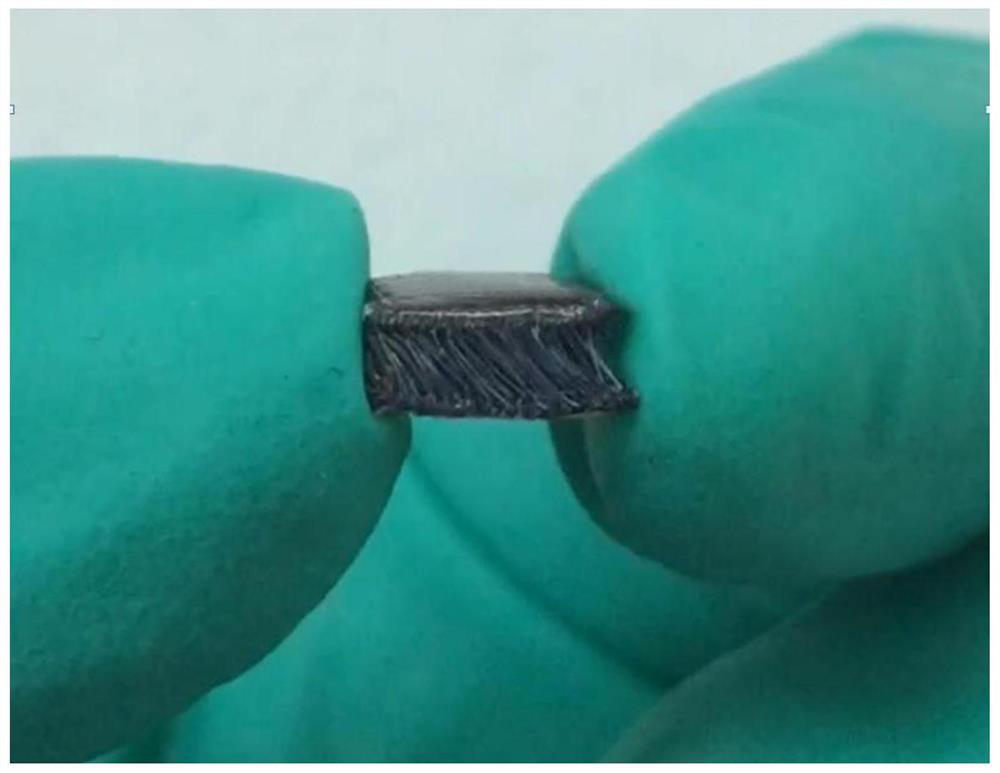

[0047] S2. Use a three-dimensional fabric (10mm×10mm×3mm) with a hollow heat-insulating layer inside as a fiber substrate, immerse it in the thermoelectric composite solution prepared in step S1, take it out after ultrasonic treatment for 2 hours, and dry it at 130° C. for 15 minutes. Then it was immersed in ethylene glycol solution for 2 hours, and after taking it out, it was dried in vacuum at 130° C. for 5 minutes to obtain a fiber substrate with a thermoelectric material adsorption cap...

Embodiment 2~7 and comparative example 1~2

[0050] Examples 2 to 7 respectively provide a method for preparing a high-efficiency fiber-based thermoelectric energy supply material. Compared with Example 1, the difference is that the content of photothermal nanoparticles in the colloidal photothermal material in step S3 or The thickness of the photothermal film and other steps are the same as in Example 1, and will not be repeated here. The content of photothermal nanoparticles and the thickness of the photothermal film corresponding to each embodiment are shown in Table 1.

[0051] Comparative Examples 1 and 2 respectively provide a fiber-based thermoelectric energy supply material. Compared with Example 1, the difference is that no photothermal nanoparticles are added in Step S3 of Comparative Example 1; while in Step S3 of Comparative Example 2 Photothermal nanoparticles with a mass fraction of 3.5% were added to form a photothermal film with a thickness of 200 μm; the remaining steps of Comparative Examples 1-2 were c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com