Flexible sensor array

A flexible sensor and array technology, applied in the field of flexible sensors, can solve the problems of less research on flexible array sensors, low material utilization, and low efficiency, and achieve the effect of simple structure, high material utilization, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0029] In the flexible sensors of the prior art, the preparation of the pressure-sensitive film is mostly achieved by means of uniform glue, etc. After curing and molding, the pressure-sensitive layer of the desired shape is obtained from the film. This process is too inefficient and the material utilization The efficiency is also low, which is not suitable for the preparation of large-area sensing arrays.

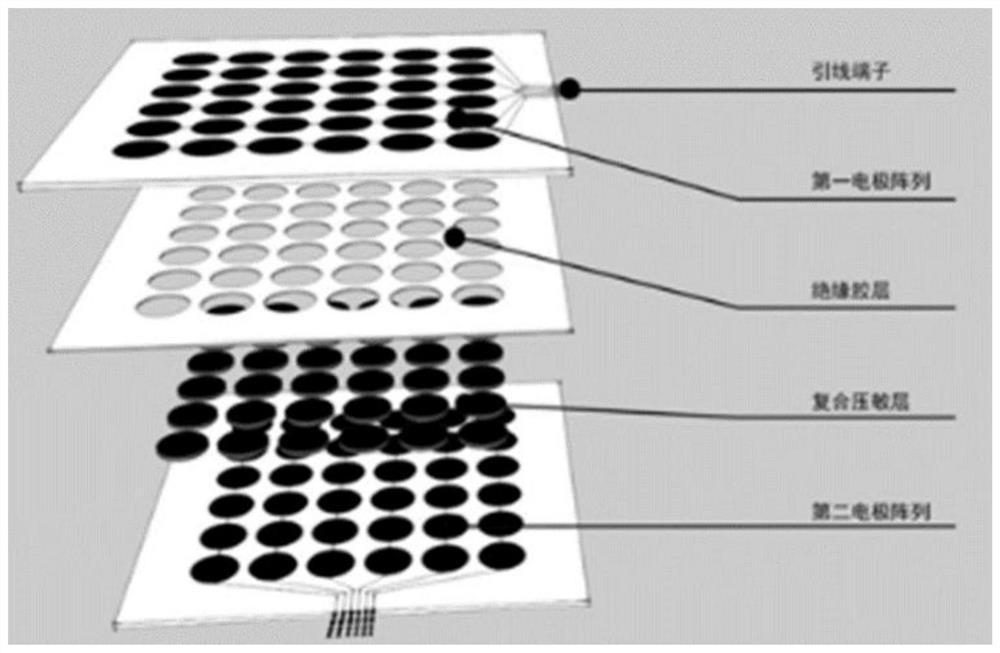

[0030] see figure 1 , which is a structural block diagram of a flexible sensor array provided by the present invention, which adopts a "sandwich" type sandwich structure, and sequentially arranges a first electrode array substrate, an insulating adhesive layer, a composite pressure-sensitive layer and a second electrode array substrate, wherein, the Both the first electrode array substrate and the second electrode array substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com